+86 13600513715

+86 13600513715 Will your Screw Press equipment experience clogging during operation

What is a spiral stacking dewatering machine?

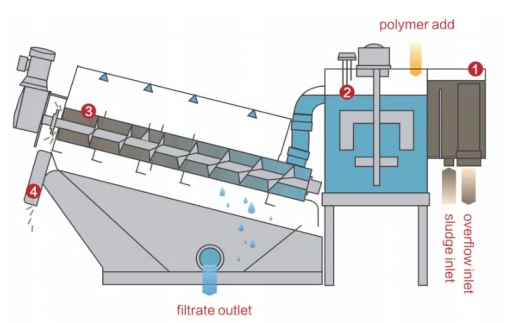

The Screw Press Sludge Dewatering machine is a new type of solid-liquidseparation equipment that utilizes the principle of screw extrusion. lt appliespowerful extrusion force generated by changes in screw diameter and pitch,along with the tiny gaps between the movable and fixed rings, to achievesludge dewatering.What is a spiral stacking dewatering machine?

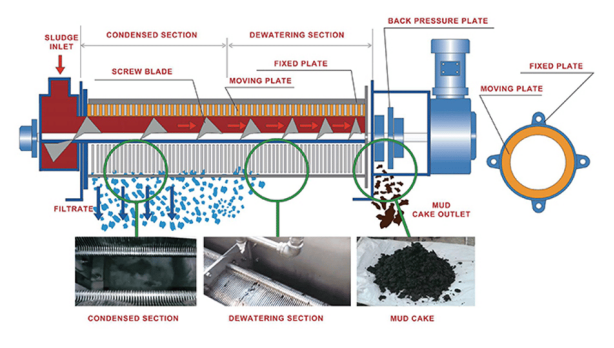

Components of the Screw Press Machine

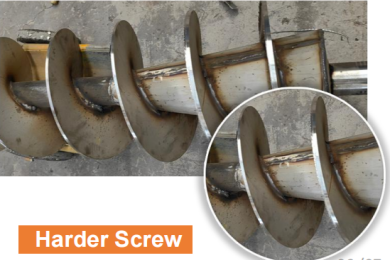

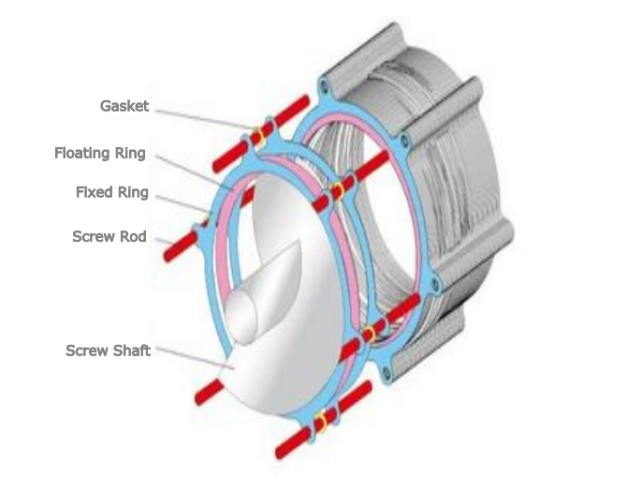

- Screw PressBody: Composed of fixed rings, movable rings, a spiral shaft, screws, spacers, and several connecting plates. The fixed rings are connected by six screws, with spacers and movable rings placed between them. Both fixed and movable rings are made of wear-resistant materials to ensure long machine life. The spiral shaft runs through the fixed and movable rings, with the movable rings loosely fitted on the shaft.

- Spiral Shaft: Consists of the shaft and spiral blades. The shaft is welded from solid and hollow shafts. During assembly, the solid and hollow shafts are first welded, then rough-turned to ensure coaxiality, and finally, the spiral blades are fully welded to the shaft.

- Drive Unit: The power source of the equipment, directly affecting overall performance. High-performance motors are typically used, with a protection rating of IP54 and insulation class F.

- Filtrate Trough: A welded plate structure for collecting filtrate squeezed out by the spiral stacking body. The trough is connected to the frame with screws and features flanges on the sides for external connections.

- Mixing System: Ensures thorough mixing of sludge and chemicals to form flocs before entering the spiral stacking body for dewatering.

Dewatering Principle of the Screw Press Machine

- Concentration: As the spiral shaft rotates, the multiple fixed and movable rings move relative to each other, allowing water to filter out through the gaps under gravity, achieving rapid concentration

- Dehydration: The concentrated sludge moves forward with the rotation of the spiral shaft. The pitch of the spiral shaft and the gaps between the rings gradually decrease, compressing the sludge. Under the resistance of the back-pressure plate at the outlet, internal pressure builds up, continuously squeezing out water and increasing the solid content of the filter cake.

- Self-Cleaning: The rotation of the spiral shaft drives the movable rings, enabling continuous self-cleaning through the movement between fixed and movable rings, effectively avoiding clogging issues common in traditional dewatering machines.

Operation of the Screw Press Machine

- Start the spray device ten minutes before operation. Sludge enters through the feed inlet, with excess flowing back through the overflow port to prevent spillage.

- The sludge flows into the flocculation mixing tank, combines with chemicals to form flocs, and enters the dewatering body for concentration and dehydration.

- Clear water flows out through the gaps between the fixed and movable rings into the collection trough, while the sludge is increasingly compressed by the spiral shaft, eventually discharged from the outlet.

- Turn on the spray device half an hour before shutdown to clean the spiral shaft and rings of residual sludge and debris.

- The entire process is automated, reducing costs.

Advantages of the Screw Press Machine

- Wide Applicability:Suitable for sludge from municipal wastewater, food, beverage, chemical, leather, welding materials, paper, printing, pharmaceutical, and other industries.

Effective for both high- and low-concentration sludge. For low-concentration sludge (2000 mg/L or lower), no concentration or storage tanks are needed, reducing construction costs and minimizing phosphorus release and anaerobic odor.

- Compact Design:Integrates the control cabinet, measuring tank, flocculation mixing tank, and dewatering body.

Small footprint, easy maintenance, and lightweight.

- Resistant to Clogging:Self-cleaning function eliminates the need for frequent washing to prevent clogging, reducing water usage and internal circulation load.Effective for oily sludge dewatering.

- Low-Speed Operation:Spiral shaft speed is only 2–3 rpm, ensuring low power consumption.

Minimal faults, low noise and vibration, and safe operation.

- Easy Operation:Automated 24/7 operation through linkage with dosing machines, sludge pumps, and chemical pumps via the control cabinet.

Short daily maintenance time and simple procedures.

- Durable:Mostly made of stainless steel for extended lifespan.

Only the spiral shaft and movable rings need replacement, with long service intervals.

Screw Press Common Faults and Solutions

- Clogging or Jamming of the Dewatering Body

Causes:

- Poor equipment quality, especially uneven spiral shafts or rings.

- Sludge properties: High inorganic content, coarse particles, or rapid separation can lead to low mobility and clogging.

- Improper operation, such as overloading or failure to clean before/after use.

Solutions:

- Run the machine idle for 10 minutes before use and 30 minutes after, with spray cleaning.

- For minor clogs, reverse the spiral shaft or use spray cleaning.

- For severe clogs, stop operation, flush with water, or disassemble the shaft for cleaning.

- Wet Sludge Output

- Poor flocculation due to improper chemical selection, dosage, or dissolution.

- Incorrect equipment settings, such as spindle speed or back-pressure plate gap.

Solutions:

- Optimize chemical selection and dosage based on sludge properties.

- Adjust the back-pressure plate gap and feed flow with professional guidance

- Screw Press Deformed Rings

Causes:

- Low-quality rings or insufficient thickness.

- Excessive feed flow beyond machine capacity.

- Sludge containing sand, oil, glue, or solid waste.

Solutions:

- Prioritize equipment quality and after-sales service when purchasing.

- Install an overflow pipe to regulate feed flow.

- Add filtration for sludge with large debris or metal impurities.

If you are looking for a high-performance Screw Press tailored to your specific needs, contact Juntai’s expert technical team for customized solutions. Our professional engineers will provide you with the most suitable equipment and comprehensive support to ensure optimal performance and longevity.

Reach out to Juntai today and let us help you achieve efficient and reliable sludge dewatering!