+86 13600513715

+86 13600513715 What is MBBR Media? Engine of Biofilm Wastewater Treatment

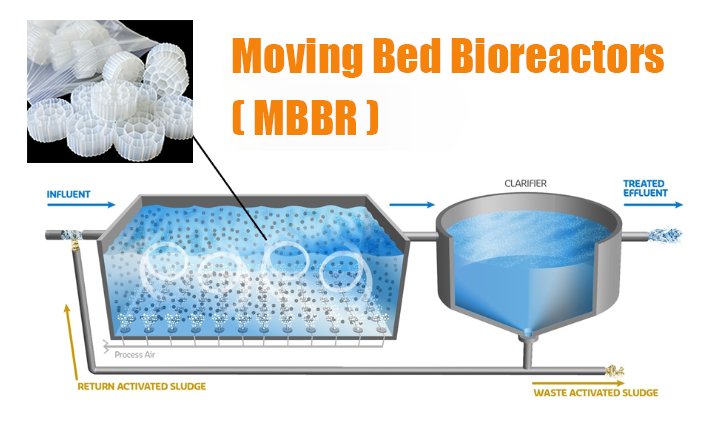

what is MBBR?

Mbbr Media (Moving Bed Biofilm Reactor media) are specially designed plastic carriers that serve as the growth surface for beneficial microorganisms in wastewater treatment systems. These tiny, free-floating elements—also known as biofilm carriers, MBBR filter media, or biochips—revolutionize biological treatment by maximizing microbial density without clogging. In an MBBR system, thousands of these media circulate within MBBR tanks, enabling efficient removal of organic pollutants, nitrogen, and phosphorus from municipal and industrial wastewater. Globally adopted from WWTPs (Wastewater Treatment Plants) to compact STPs (Sewage Treatment Plants), MBBR technology leverages this dynamic biofilm reactor process to outperform conventional methods.

1 Core Principles of MBBR Technology

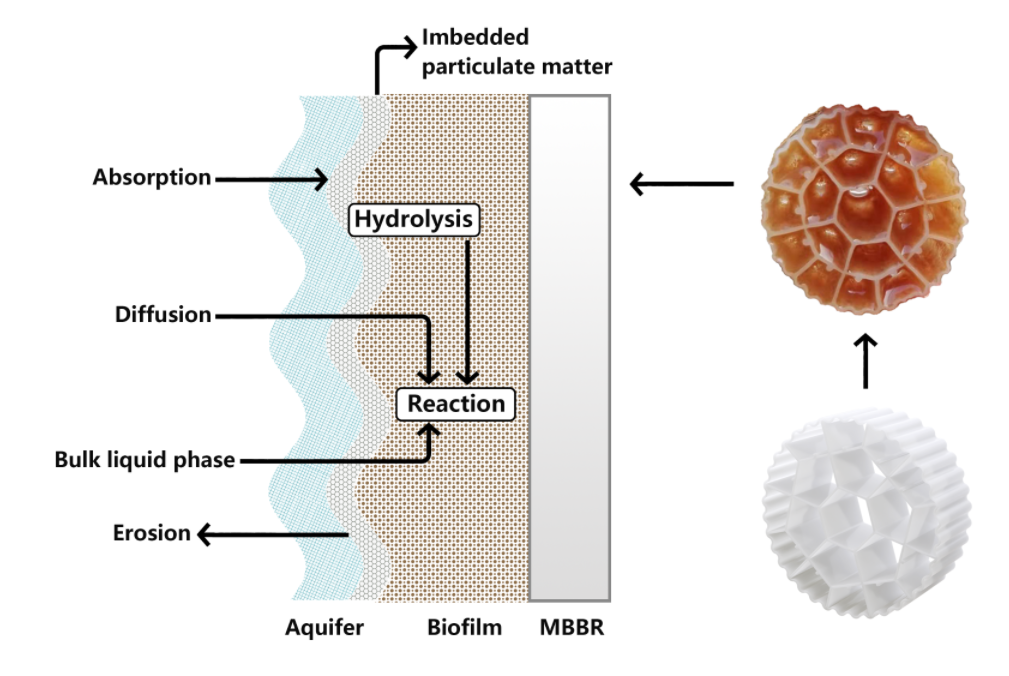

MBBR wastewater treatment relies on biofilm growth on protected internal surfaces of plastic carriers. Unlike fixed-film reactors, these mbbr biofilm carriers move freely within aerated or anoxic tanks, propelled by aeration or mixers. This motion ensures continuous contact between wastewater and biomass, enhancing treatment efficiency. The moving bed bioreactor process decouples hydraulic retention time (HRT) from sludge age (SRT), allowing slow-growing microbes (like nitrifying bacteria) to thrive. Studies show MBBR systems achieve >95% COD removal and >94% ammonia reduction under optimal conditions.

2 Structure and Materials of MBBR Media

2.1 Geometric Design

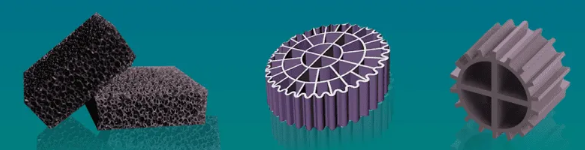

Most mbbr carrier media feature a cross-linked, honeycombed structure (e.g., 10–25 mm diameter cylinders) with fins or ridges. This design maximizes protected surface area (typically 500–1,200 m²/m³) while minimizing weight. The high void ratio (>90%) prevents clogging and supports rapid mass transfer of substrates like BOD, NH₄⁺, and O₂.

2.2 Material Composition

-

HDPE (High-Density Polyethylene): Standard for aerobic MBBR systems; balances durability and biofilm adhesion.

-

Polyurethane Sponge: Used in modified carriers (e.g., zeolite-infused foams), boosting microbial load by 80.3% and enhancing nutrient removal.

-

Specialized Polymers: For anaerobic MBBR or high-salinity applications, materials resist chemical degradation.

3 Key Performance Parameters of MBBR Media

Table: Comparative Properties of Common MBBR Media Types

| Media Type | Material | Surface Area (m²/m³) | Density (g/cm³) | Fill Ratio (%) | Use Case |

|---|---|---|---|---|---|

| MBBR 04/19/64 | HDPE | 500–800 | 0.95–0.98 | 25–70 | Municipal STP MBBR |

| Sponge Media | PU + Zeolite | 800–1,200 | 0.98–1.02 | 15–40 | High-strength ammonia removal |

| Anaerobic Biochips | PP/PVDF | 350–600 | 1.02–1.05 | 30–60 | Anaerobic MBBR reactors |

| IFAS Hybrid Media | HDPE/Sponge | 600–900 | 0.96–1.00 | 20–50 | Upgrading activated sludge |

Contact us for all MBBR model specifications

4 Advantages of MBBR Media in Treatment Systems

-

High Load Resilience: Media retain biomass during flow surges, enabling stable mbbr wastewater treatment process during storms or industrial shocks.

-

Compact Footprint: 3× smaller than activated sludge tanks due to concentrated biomass (8–12 g/L MLSS).

-

Low Sludge Yield: Sludge production drops by 75–80% compared to conventional processes, reducing disposal costs.

-

Modular Flexibility: MBBR tanks retrofit into existing plants (e.g., clarifiers converted to MBBR) or combine with membranes (MBR) or settlers (Tube Settlers).

5 Applications Across Wastewater Sectors

5.1 Municipal Sewage (STP MBBR)

In mbbr stp plants, carriers treat low-C/N sewage to meet Class 1A standards (COD < 50 mg/L, NH₄⁺ < 5 mg/L). Multi-stage moving bed biofilm reactor mbbr technology achieves simultaneous nitrification/denitrification.

5.2 Industrial Effluents

-

Food Processing: Removes fats/O&G via biofilm encapsulation.

-

Pharmaceuticals: Biofilm reactors for wastewater treatment degrade complex organics under extended SRTs.

5.3 Advanced Nutrient Removal

Anaerobic MBBR + aerobic mbbr system configurations target nitrogen/phosphorus, ideal for sensitive watersheds like Lake Simcoe.

6 Key Components of an MBBR System

6.1 Media Retention Screens

Perforated sieves (1–5 mm openings) retain mbbr filter media while allowing effluent passage. Backwashable designs prevent blinding.

6.2 Aeration Systems

Fine-bubble diffusers provide oxygen and maintain media suspension (≥0.3 Nm³/h·m³). Smart DO control optimizes energy use.

6.3 Mixers for Anoxic Zones

Slow-speed agitators keep media fluidized in denitrification/anammox tanks.

7 Hybrid Systems: Boosting Performance

-

IFAS-MBBR: Combines suspended sludge with mbbr carrier media, doubling nitrification rates.

-

MBBR-MBR: MBR membranes polish mbbr treatment effluent for reuse (e.g., >95% COD removal in restaurant wastewater).

-

Chemical-PMBR: Alum dosing enhances phosphorus removal where bio-P is insufficient.

8 Selecting MBBR Media: Critical Factors

-

Surface Area vs. Void Space: High area (>800 m²/m³) suits low-load sewage; larger voids prioritize stormwater/clogging resistance.

-

Material Compatibility: HDPE for municipal; PVDF for chemical-laden effluents.

-

Cost: MBBR price ranges $750–$2,000/m³ based on material and features. Zeolite-modified media cost 15–20% more but cut nutrient removal costs long-term.

Contact us for MBBR calculator

Conclusion: Why MBBR Media Dominate Modern Bio-Treatment

MBBR media transform biological wastewater treatment by merging biofilm resilience with suspended growth kinetics. Whether in mbbr wwtp retrofits or new mbbr system for wastewater treatment, these carriers enable compact, efficient, and adaptable purification. As innovations like electrically conductive or nano-enhanced media emerge, MBBR technology will continue redefining standards for water reuse and discharge compliance.