+86 13600513715

+86 13600513715 Tube Settler Optimization Guide: Municipal, Industrial & High-TSS Applications

Optimizing Tube Settler Performance Across Wastewater Types: Design & Operational Strategies

Introduction: Hydraulic Efficiency in Variable Matrices

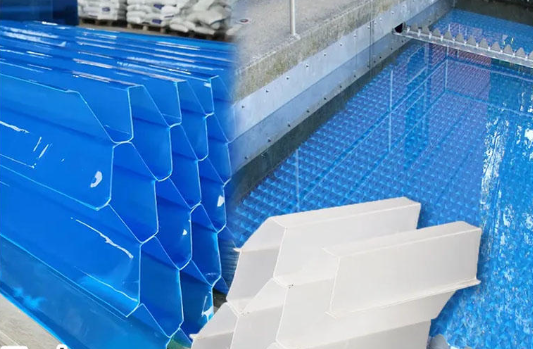

Tube Settlers enhance sedimentation by increasing effective settling area through inclined plate geometry. Their performance varies significantly with wastewater characteristics—floc density, viscosity, and solids loading dictate loading rates, spacing, and material selection. This engineering analysis decodes adaptations required for municipal, industrial, high-TSS, and hypersaline applications to achieve >95% TSS removal.

1. Municipal Wastewater: Managing Light Flocs & Peak Flows

1.1 Hydraulic Loading Optimization

-

Floc Characteristics:

-

Density: 1.01-1.03 g/cm³

-

Size: 10-100 µm

-

-

Design Adjustments:

-

Tube spacing: 50-75 mm (promotes floc coalescence)

-

Inclination: 60° angle balances cleaning vs. efficiency

-

-

Flow Control:

-

Peak flow velocity: ≤1.0 m/h

-

Lamella spacing: 100-150% of floc size

-

1.2 Chemical Conditioning Requirements

| Parameter | Without Polymer | With Anionic Polymer |

|---|---|---|

| Overflow Rate (m/h) | 1.0-1.5 | 2.0-3.0 |

| Floc Settling Velocity | 1.2 m/h | 3.5 m/h |

| Turbidity Removal | 85-90% | 92-97% |

2. Industrial Wastewater: High Density Solids & Scour Risk

2.1 Heavy Metal & Sludge Handling

-

Material Selection:

-

Acidic streams (pH<4): CPVC or PP-EPDM blend

-

Oily wastewater: Hydrophobic coated PVC

-

-

Geometry Modifications:

-

Tube length: ≤1.5 m (prevents sludge compaction)

-

Module height: 0.6-0.8 m (reduces static pressure)

-

2.2 Viscosity Compensation

-

Temperature-Viscosity Adjustment:

-

For 30°C vs 10°C: Reduce loading rate by 35%

-

-

Shear Control:

-

Inlet baffle design: Energy dissipation <5 W/m³

-

3. High-TSS Streams (>2,000 mg/L): Preventing Fouling

3.1 Self-Cleaning Configurations

-

Oscillating Module System:

-

15° auto-rotation every 4 hours

-

Sloughs off accumulated solids

-

-

Air Scour Integration:

-

Pulse intensity: 50 N/m² at 10 min intervals

-

3.2 Tube Geometry Optimization

Table: Settler Parameters for High-TSS Applications

| TSS Range (mg/L) | Tube Diameter (mm) | Spacing (mm) | Backwash Frequency |

|---|---|---|---|

| 2,000-5,000 | 80-100 | 60-70 | Weekly |

| 5,000-10,000 | 100-120 | 70-85 | Daily |

| >10,000 | 120-150 | 85-100 | Continuous air assist |

4. Hypersaline Wastewater (>5% TDS): Density Effects

4.1 Buoyancy Compensation

-

Settling Velocity Equation:

-

-

Where increases 8% per 3% TDS

-

-

Operational Response:

-

Reduce overflow rate by 20% per 1% TDS > seawater

-

4.2 Corrosion Mitigation

-

Material Specification:

-

Brackish water (1-3%): 316L stainless steel supports

-

Brine (>5%): FRP with vinyl ester resin

-

-

Galvanic Protection:

-

Sacrificial anodes (zinc) for submerged metal parts

-

5. Failure Analysis & Corrective Actions

Table: Wastewater-Specific Troubleshooting

| Issue | Municipal | Industrial | High-TSS | Hypersaline |

|---|---|---|---|---|

| Tube clogging | Increase polymer dose | Install pre-screening | Enable auto-oscillation | Reduce tube length |

| Floc carryover | Reduce flow 15% | Adjust pH to 7.5-8.0 | Lower inlet velocity | Increase tube spacing |

| Corrosion damage | Not applicable | Replace with CPVC | Not applicable | Apply cathodic protection |

| Sludge bridging | Water jet cleaning | Add defoamers | Air scour upgrade | Reduce inclination to 55° |

Conclusion: Context-Driven Hydraulic Design

Tube settler efficiency hinges on synchronizing tube geometry, material science, and hydraulic control with wastewater properties. Municipal plants prioritize floc promotion, industrial systems require corrosion resistance, high-TSS streams demand anti-fouling features, and hypersaline environments need density compensation. Real-time flow modulation extends performance beyond conventional clarifiers.