+86 13600513715

+86 13600513715 Screw Press Dewatering Machines: Slash Sludge Volume by 80%

The Unsung Hero of Wastewater Plants: How Screw Press Dewatering Machines Slash Sludge Costs

What Is a Screw Press Dewaterer? (And Why Every Plant Needs One)

A screw press dewatering machine is the workhorse of sludge management - a mechanical system that reduces sludge volume by removing 70-85% water content through continuous pressure filtration. Unlike centrifuges or belt presses, it uses a slow-rotating screw inside a perforated screen to gently squeeze sludge, producing cake solids of 18-25% dryness with minimal energy. This transforms liquid waste (0.5-1.5% solids) into shovel-ready material, cutting disposal costs by up to 80%.

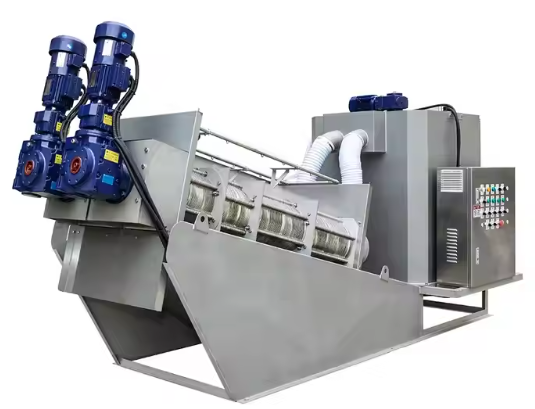

Anatomy of a Modern Screw Press: Key Components Explained

1. The Progressive-Depth Screw Shaft

-

Variable pitch design: Wide flights at inlet → narrow flights at discharge

-

Compression ratio: From 5:1 to 3:1 (adjustable via back-pressure cone)

-

Self-cleaning flights: Scraper blades prevent clogging (critical for sticky sludges)

2. Multi-Layer Screen System

| Screen Type | Function | Material |

|---|---|---|

| Pre-drainage | Removes free water rapidly | 2mm wedge wire |

| Primary | Captures mid-size solids | 0.75mm laser-cut slots |

| Finishing | Polishes cake dryness | 0.25mm micro-perfs |

3. Intelligent Control Package

-

Torque monitoring: Auto-adjusts pressure based on sludge rheology

-

Flocculant dosing AI: Optimizes polymer use (±0.1% accuracy)

-

Cloud-based OEE tracking: Predicts wear parts replacement

Why Screw Presses Outperform Alternatives

*Table: Operational comparison for municipal sludge (50 T/day capacity)*

| Parameter | Screw Press | Centrifuge | Belt Press |

|---|---|---|---|

| Dryness (%) | 20-25 | 18-22 | 15-20 |

| Power (kWh/T sludge) | 5-8 | 25-40 | 10-15 |

| Noise Level (dB) | 65-70 | 85-95 | 75-80 |

| Footprint (m²) | 15 | 35 | 25 |

| Operator Attention | 15 min/shift | 90 min/shift | 45 min/shift |

| Wash Water (m³/T) | 0.1 | 0.3 | 1.5 |

The Science Behind Efficient Dewatering

1. Shear-Thinning Fluid Dynamics

Municipal sludge behaves as non-Newtonian fluid:

-

Viscosity drops under shear: Screw rotation (2-5 RPM) liquefies sludge for drainage

-

Thixotropic recovery: Solids re-thicken during low-shear compression stages

Properly designed Sludge Dewatering machines exploit this physics to achieve 3x higher solids capture than brute-force methods.

2. Flocculant-Sludge Synergy

Optimal dewatering requires polymer bridging:

-

Cationic charge density: 40-60% for activated sludge

-

Molecular weight: 10-15 million Daltons

-

Injection points: Pre-screening + mid-barrel boosters

Juntai’s screw press systems reduce polymer consumption by 35% through multi-zone injection.

Real-World Applications: Where Screw Presses Shine

1. Municipal Wastewater Plants

-

Volume reduction: 100m³ sludge → 8m³ cake (88% reduction)

-

Cost savings: $120/T disposal → $40/T after dewatering

-

Landfill diversion: Cake meets EPA 503 Class B standards

2. Food & Beverage Industry

-

Brewery waste: Dewaters spent yeast to 25% DS

-

Dairy processing: Handles high-fat sludge without grease blinding

-

Poultry plants: Removes feathers/fat from DAF sludge

3. Marine & Offshore

-

Compact design: 2m x 3m units for platform installations

-

Corrosion resistance: 316L stainless steel construction

-

Zero-discharge: Closed-loop wash water recycling

Selecting Your Screw Press: Technical Checklist

| Factor | Municipal Sludge | Industrial Sludge |

|---|---|---|

| Screen Opening | 0.25-0.5mm | 0.5-0.75mm |

| Compression Ratio | 4:1 | 3:1 |

| Screw RPM | 2-3 RPM | 0.5-2 RPM |

| Flocculant Type | Cationic, medium MW | Anionic, high MW |

| Back Pressure | 0.3-0.5 bar | 0.2-0.4 bar |

Future Innovations: Smart Dewatering

1. Self-Learning Polymer Optimization

-

Real-time viscometry: Adjusts dosing based on sludge viscosity

-

Machine vision: Analyzes floc size via camera systems

-

Digital twin integration: Simulates dewatering before physical changes

2. Waste-to-Energy Integration

-

Methane capture: Dewatered sludge → anaerobic digestion → CHP

-

Thermal hydrolysis: Pre-treats sludge for 20% higher biogas yield

-

Pyrolysis systems: Converts cake to biochar at 600°C

3. Nano-Material Screens

-

Graphene-coated wires: Prevent blinding permanently

-

Shape-memory alloys: Auto-clear jams by thermal expansion

-

Antimicrobial surfaces: Inhibit filamentous bacteria growth