+86 13600513715

+86 13600513715 PU MBBR vs HPU MBBR: Technical Comparison & Selection Guide

PU MBBR vs HPU MBBR: Technical Comparison & Selection Guide

1. PU MBBR (Polyurethane Moving Bed Biofilm Reactor)

Core Mechanism:

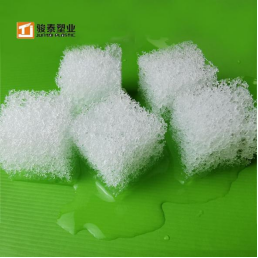

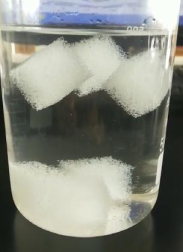

PU MBBR utilizes medium-density polyurethane foam carriers (density 0.3-0.6 g/cm³) with macroporous structures (pore size 50-300μm). These floating carriers provide:

Biofilm Attachment Surface: The open-cell foam structure offers 500-800 m²/m³ surface area for microbial colonization.

Oxygen Transfer: Macroporosity facilitates dissolved oxygen diffusion to both outer and inner biofilm layers.Self-Cleaning Effect: Continuous motion from aeration scrubs excess biomass, maintaining optimal biofilm thickness (typically 100-300μm).

Typical Applications:

Municipal wasteWater Treatment (BOD < 300 mg/L)

Low-strength industrial effluents (e.g., dairy, brewery)

Nitrification/denitrification stages

2. HPU MBBR (High-Density Polyurethane MBBR)

Core Mechanism:

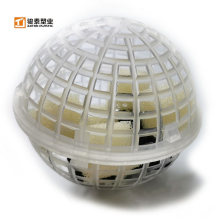

HPU employs ultra-porous carriers (density >0.9 g/cm³) with hierarchical pore structures:

Macropores (50-100μm): Enable rapid initial biofilm formation.

Mesopores (2-50μm): Provide secondary colonization sites.

Micropores (<2nm): Increase functional surface area to 1000-1500 m²/m³.

Key Features:

Stratified Biofilm Development: Outer layers handle fast-growing heterotrophs, inner pores host slow-growing nitrifiers/ANAMMOX bacteria.

Hydraulic Stability: Higher density prevents carrier washout in high-flow systems.

Clogging Resistance: Interconnected pores maintain activity even with 30-40% SS in influent.

Typical Applications:

High-load industrial wastewater (COD > 5000 mg/L)

Refractory organics degradation (e.g., petrochemicals)

Space-limited plant upgrades

Technical Comparison

| Parameter | PU MBBR | HPU MBBR |

| Biofilm Kinetics | First-order degradation (k=0.5-1.2 h⁻¹) | Zero-order kinetics (k=2-4 h⁻¹) |

| Oxygen Utilization | 1.8-2.5 kg O₂/kg CODremoved | 1.2-1.6 kg O₂/kg CODremoved |

| Sludge Yield | 0.3-0.5 kg TSS/kg COD | 0.15-0.25 kg TSS/kg COD |

| Footprint | 0.8-1.2 m²/m³ wastewater | 0.3-0.6 m²/m³ wastewater |

Selection Guidelines

Choose PU MBBR when:

Treating wastewater with fluctuating loads

Prioritizing capital cost over operational savings

Existing infrastructure has adequate tank volume

Opt for HPU MBBR when:

Treating recalcitrant compounds requiring long SRT

Space constraints demand intensive treatment

High salinity/oil content (up to 5,000 mg/L)

Maintenance Considerations

PU Carriers: Require annual inspection for physical wear (typical lifespan 8-10 years)

HPU Carriers: Need quarterly pore structure analysis via micro-CT scanning (lifespan 12-15 years)

For project-specific recommendations, our engineering team can perform:

① Wastewater characterization (respiratory tests, OUR/SOUR analysis)

② Computational fluid dynamics (CFD) modeling for carrier distribution

③ Pilot-scale verification (minimum 90-day testing)

The optimal selection depends on water quality, load characteristics, and project budget. Pilot testing is recommended for complex wastewater. Contact Juntai Tech Team for customized solutions!