+86 13600513715

+86 13600513715 MBR Membrane Technology in Wastewater Treatment: Applications & Advantages Over Traditional Methods

Why MBR Technology? Key Benefits

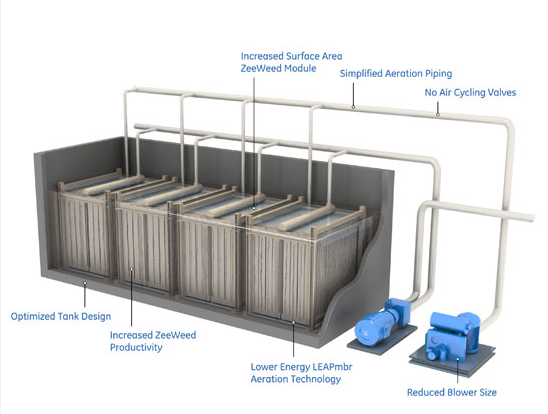

MBR (Membrane Bio-Reactor) combines biological treatment with ultrafiltration membranes to achieve >95% SS removal and effluent turbidity <1 NTU. Compared to conventional activated sludge processes:

-

60% smaller footprint (no secondary clarifiers)

-

30-50% less sludge production

-

Stable compliance with stringent discharge standards (e.g., TN <15 mg/L).

MBR Applications in Critical Scenarios

1. Space-Constrained Urban Plants

-

Case Study: Beijing Huai Fang WWTP (60,000 m³/day) uses underground MBR to meet Class IV water standards while converting surface space into a public park.

-

Juntai Solution: Modular MBR units reduce construction area by 65% vs. traditional layouts.

2. High-Strength Industrial Wastewater

-

Technical Edge: MBR maintains MLSS up to 18,000 mg/L (5x higher than activated sludge), ideal for chemical/pharmaceutical wastewater (COD >2,000 mg/L).

-

Juntai Advantage: Anti-fouling PVDF membranes with 0.1μm pores resist oils and surfactants.

3. Water Reuse Projects

-

Performance: MBR effluent meets ISO 14000 reuse standards for irrigation/cooling, increasing recycling rates by 40%.

-

Integrated System: Pair with Juntai’s Tube Settlers for SS <5 mg/L.

MBR vs. Activated Sludge: Technical Comparison

| Parameter | Activated Sludge | MBR |

|---|---|---|

| Footprint | 1,000 m² (reference) | 400 m² |

| Effluent SS | 20-30 mg/L | <1 mg/L |

| Sludge Yield | 0.8 kg/kg COD | 0.4 kg/kg COD |

| Shock Load Tolerance | Moderate | High (MLSS auto-regulation) |

Key Takeaway: MBR eliminates clarifiers, reduces operational costs, and ensures consistent effluent quality.

MBR vs. AAO: How to Choose?

-

AAO Best For:

-

Municipal wastewater (BOD <300 mg/L)

-

Nutrient removal (TN <20 mg/L, TP <1 mg/L)

-

Budget-friendly projects with ample space.

-

-

MBR Preferred When:

-

Treating high COD (>1,000 mg/L) industrial streams

-

Space is limited (e.g., underground plants)

-

Direct water reuse is required.

-

Case Example: A Liaoning petrochemical plant achieved COD <120 mg/L using Juntai’s AO-MBR hybrid system for 2,000 mg/L influent COD.

Why Juntai MBR Systems?

-

Energy Efficiency: Integrated Disc Diffusers (O₂ transfer ≥30%) lower energy use by 25%.

-

Durability: HDPE membrane modules withstand pH 2-12 and 45°C temperatures.

-

Smart Operation: IoT sensors enable real-time TMP monitoring and predictive cleaning.

CTA: Upgrade to Advanced MBR Solutions!

Contact Juntai for a FREE process design and feasibility report.