+86 13600513715

+86 13600513715 MBBR Wastewater Adaptation Guide: Municipal, Industrial, Saline & Cold Climate

Adaptive MBBR Performance Across Wastewater Types: Process Optimization & Carrier Dynamics

Introduction: Biofilm Reactor Versatility in Variable Matrices

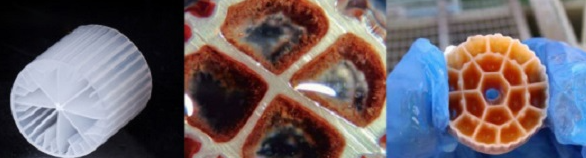

Moving Bed Biofilm Reactors (MBBR) excel in diverse wastewater streams through biofilm ecology adaptation. Unlike suspended growth systems, MBBR's immobilized biomass resists shock loads, sustains slow-growing specialists (e.g., nitrifiers), and maintains activity at suboptimal temperatures. This analysis decodes how carrier design, hydraulic regimes, and microbial consortia interact with four critical wastewater profiles: municipal, industrial organic, hypersaline, and cold climate effluents.

1. Municipal Wastewater: Nutrient Removal Dynamics

1.1 Carbon-to-Nitrogen (C/N) Ratio Management

-

Low C/N (<5:1):

-

Challenge: Insufficient carbon for denitrification

-

Solution:

-

Anoxic zone methanol dosing (20-30 mg/L)

-

Partial bypass of primary clarifiers

-

-

-

High C/N (>10:1):

-

Risk: Excessive heterotrophs outcompiting nitrifiers

-

Mitigation:

-

Step-feed distribution

-

Carrier filling ratio >50%

-

-

1.2 Biofilm Population Stratification

| Biofilm Depth | Dominant Microbes | Metabolic Function | Optimal DO (mg/L) |

|---|---|---|---|

| 0-100 µm | Zoogloea spp. | BOD removal | 0.5-2.0 |

| 100-300 µm | Nitrosomonas spp. | Ammonia oxidation | 1.5-3.0 |

| >300 µm | Nitrobacter spp. | Nitrite oxidation | 2.0-4.0 |

2. Industrial Organic Wastewater: Handling Toxicity & Load Fluctuations

2.1 Inhibitor Mitigation Protocols

-

Lipids/Fats (>100 mg/L):

-

Carrier Selection: Hydrophobic EPDM surfaces

-

Operational Response: Increase shear stress (aeration >0.4 m/s)

-

-

Phenolic Compounds:

-

Adsorption Pre-treatment: Activated carbon columns (EBCT ≥15 min)

-

Bioaugmentation: Pseudomonas putida strains inoculation

-

2.2 High-Strength COD Loading Strategies

-

Two-Stage MBBR Configuration:

-

Stage 1: High-porosity carriers (1000 m²/m³) at 15 kg COD/m³·d

-

Stage 2: Standard carriers (500 m²/m³) for polishing

-

-

Anaerobic-Aerobic Coupling:

-

UASB effluent → MBBR for BOD:N ratio balancing

-

3. Hypersaline Wastewater (>3% TDS): Osmo-Adaptation Mechanisms

3.1 Halotolerant Biofilm Engineering

-

Carrier Surface Modification:

-

Positively-charged coatings attract halophiles (Halomonas spp.)

-

Macro-texturing protects biofilm from salt crystallization

-

-

Salinity Grading Protocol:

-

Start at 1% TDS → increase 0.5%/day until target salinity

-

Maintain SRT >25 days

-

3.2 Performance Expectation Adjustment

| TDS Range | COD Removal Efficiency | Nitrification Rate | Carrier Fouling Risk |

|---|---|---|---|

| 1-2% | 85-92% | 0.8-1.2 gN/m²·d | Low |

| 2-3% | 75-85% | 0.5-0.8 gN/m²·d | Moderate |

| >3% | 60-75% | <0.5 gN/m²·d | High |

4. Cold Climate Operation (<10°C): Cryo-Adaptive Tactics

4.1 Biofilm Cryoprotection

-

Carrier Design:

-

Micro-porous structure (pore size 50-100 µm) traps heat

-

Insulating polymer blends (e.g., PU-EPDM)

-

-

Metabolic Stimulants:

-

Add trace elements (Ni, Co) for psychrophilic enzyme cofactors

-

Supplemental carbon (acetate) for endogenous respiration

-

4.2 Hydraulic Optimization

-

Reduced Hydraulic Loading: <1.5 m³/m²·h to prevent biofilm shear

-

Counter-Current Aeration:

-

Airflow direction opposes water flow

-

Increases contact time by 25-40%

-

5. MBBR Troubleshooting Matrix by Wastewater Type

Table: Wastewater-Specific Failure Modes & Corrective Actions

| Issue | Municipal | Industrial | Hypersaline | Cold Climate |

|---|---|---|---|---|

| Biofilm detachment | Increase DO setpoint | Reduce organic loading | Lower shear velocity | Raise temperature 2°C |

| Excessive foaming | Add silicone defoamer | Install grease removal | Salt dilution pulse | Reduce aeration intensity |

| Nitrogen removal drop | Check alkalinity | Test for cyanide | Monitor osmolarity | Verify SRT >40 days |

| Carrier clumping | Clean inlet screen | Adjust pH to 7.0-7.5 | Backwash with freshwater | Check ice formation |

Conclusion: Context-Driven Process Intensification

MBBR's efficacy hinges on aligning carrier architecture, microbial ecology, and hydraulic control with wastewater matrix properties. Municipal systems prioritize stratified biofilms, industrial units require inhibitor management, hypersaline applications demand halophile enrichment, and cold climates need thermal buffering. Real-time parameter monitoring enables dynamic adaptation exceeding conventional system resilience.