+86 13600513715

+86 13600513715 MBBR Technology: Principles, Benefits, and Pollutant Removal Explained MBBR Principles

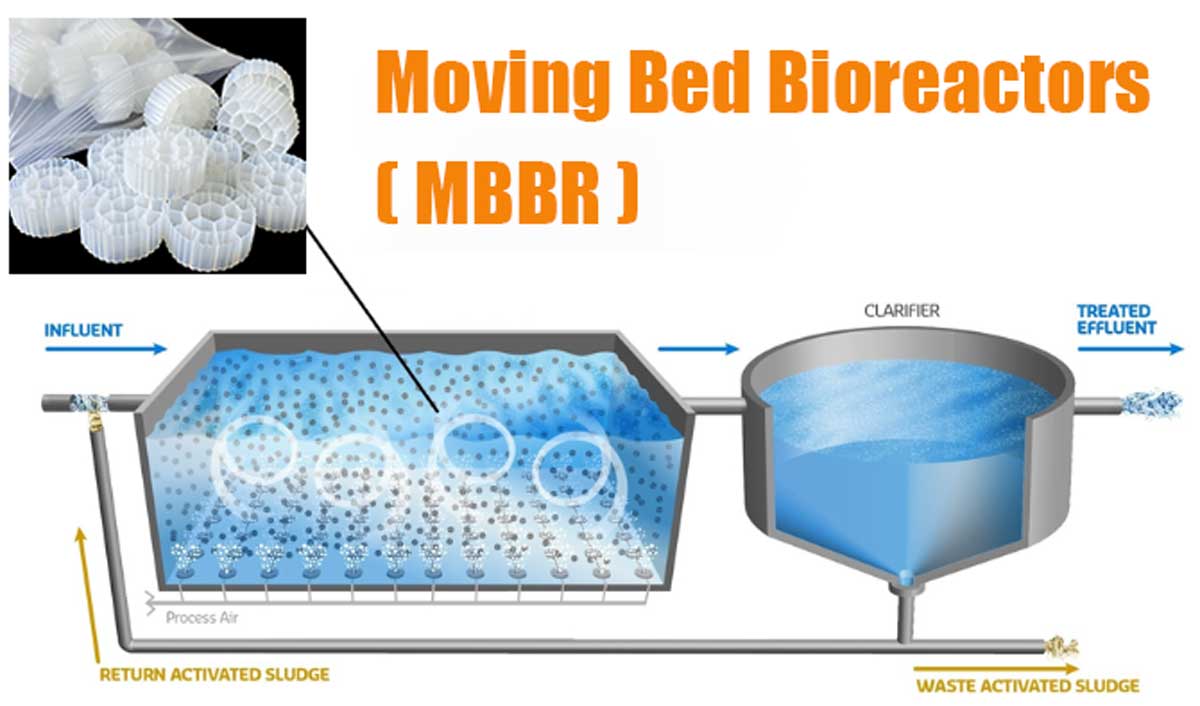

The Moving Bed Biofilm Reactor (MBBR) integrates the strengths of conventional fluidized beds and biological contact oxidation techniques, establishing itself as a highly effective wasteWater Treatment solution. The process leverages aeration and water flow in the reactor to maintain carrier movement, forming both suspended activated sludge and biofilms attached to the carriers. By utilizing the full reactor space, the MBBR maximizes the advantages of both attached and suspended biomass, achieving complementary efficiencies.

Unlike static fillers, Mbbr Media moves dynamically within the wastewater, allowing frequent and sustained interaction with contaminants, earning it the name "moving biofilm." By adding specially designed carriers with densities close to water (0.96–0.98 kg/L), the process enhances biomass growth and microbial diversity. The carriers foster a multi-phase environment of gas, liquid, and solids, allowing anaerobic bacteria to grow internally while aerobes populate the outer layers. These carriers act as micro-reactors, facilitating simultaneous nitrification and denitrification for superior pollutant removal efficiency.

Advantages of Simultaneous Nitrification and Denitrification

1.Nitrogen Reduction

MBBR effectively converts ammonium nitrogen (NH₃-N) into nitrogen gas (N₂), significantly reducing nitrogen content and mitigating water eutrophication risks.

2.Environmental Stability

This process allows nitrogen treatment under diverse conditions, such as aerobic and anoxic phases, enhancing system flexibility and operational stability.

3.Energy Efficiency

Compared to chemical methods, biological processes in MBBR achieve nitrogen removal with minimal energy consumption and chemical usage, supporting sustainable development goals.

Achieving simultaneous nitrification and denitrification requires careful control of aerobic and anoxic conditions, ensuring effective pollutant treatment and adaptability to various load levels.

What Pollutants Does MBBR Target?

1.Organic Matter

MBBR removes dissolved organic pollutants like BOD and COD with over 90% efficiency, making it ideal for municipal, industrial, and agricultural wastewater.

2.Ammonia Nitrogen

Through biological nitrification, ammonia is converted into nitrate, achieving ammonia nitrogen removal rates exceeding 90%.

3.Total Nitrogen (TN)

Combined nitrification and denitrification convert organic and ammonia nitrogen into nitrogen gas, reducing TN levels by 50%–80%, with potential for higher rates in optimized systems.

4.Total Phosphorus (TP)

While primarily a nitrogen removal process, MBBR can eliminate phosphorus with optimized operations, achieving TP reductions between 50% and 90%.

5.Suspended Solids (SS)

By forming biofilms and trapping particulates, MBBR achieves SS removal rates ranging from 50% to 90%.

6.Pathogens

The biofilm system in MBBR adsorbs and degrades some pathogens, enhancing overall water quality.

How the MBBR System Functions

Under aerobic conditions, aeration generates air bubbles that move the carriers and water, fragmenting bubbles for improved oxygen transfer and pollutant interaction. In anaerobic settings, a submerged mixer ensures full fluidization of the carriers, promoting efficient biofilm and pollutant contact.

A key factor in MBBR efficiency is the fluidization of media. Proper aeration ensures consistent media movement, enabling pollutant exchange and maintaining biofilm stability. The specific gravity of carriers varies with biofilm growth, enabling self-cleaning cycles through alternating aerobic and non-aerobic zones. Stainless steel screens prevent carriers from migrating to downstream processes, ensuring system reliability.