+86 13600513715

+86 13600513715 MBBR Rapid Biofilm Formation Technical Guide

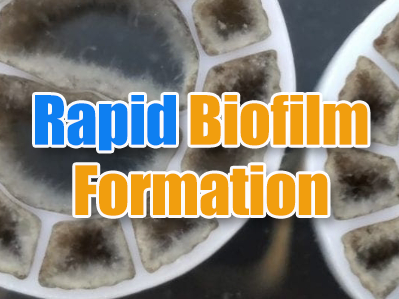

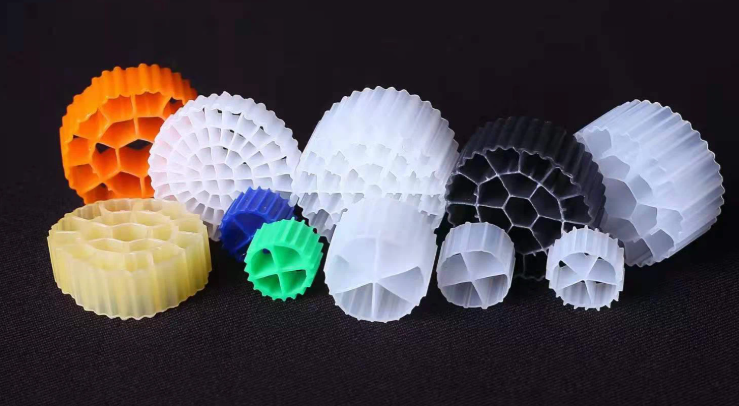

MBBR (Moving Bed Biofilm Reactor) degrades pollutants through biofilms on suspended biological carriers. The biofilm formation efficiency directly affects the system startup speed and treatment effect.

- When adding fillers, observe for any accumulation. Once accumulation occurs, stop adding. Check again the next day before resuming addition.

- During filler addition, use intermittent aeration. Continuous aeration can be maintained at night, but the aeration volume should be reduced.

- After 24 hours of operation, continuously feed water for 2 - 3 hours, then resume the above - mentioned aeration. After 48 hours of operation, observe the biofilm formation on the fillers, increase the water inflow and extend the water feeding time. Check the dissolved oxygen (DO) status in the tank, preferably maintaining it at around 1.5 - 2.0 mg/L. After 72 hours of operation, continuously feed water and gradually increase it to the design requirements. Regularly check the influent and effluent water quality. It is expected that the design water quality requirements can be met in about 7 days.

The biofilm formation process usually includes the initial microbial adsorption, biofilm growth, and maturation stages. During this process, microorganisms attach to the biological carriers in the Mbbr Reactor to form a stable biofilm. Factors such as temperature, pH value, dissolved oxygen, concentration of nutrients (such as nitrogen and phosphorus), water flow velocity, and the material and surface characteristics of the carriers can all affect the speed and quality of biofilm formation.

Factors Affecting Biofilm Formation

- Slow biofilm formation: Conditions such as low temperature, insufficient nutrients, and inappropriate pH values may lead to slow biofilm formation.

- Biofilm detachment: Excessive flow velocity, mechanical damage, or internal hypoxia caused by overly thick biofilms may lead to biofilm detachment.

- Uneven biofilm thickness: Uneven water flow distribution or carrier aggregation may result in uneven biofilm thickness, affecting the treatment effect.

- Biofilm aging: After long - term operation, biofilms may age and their efficiency may decline. Cleaning or replacing carriers is required to address this issue.

Based on Juntai's technical experience, rapid biofilm formation can be achieved through three aspects: optimizing the application of biofilm formation principles, precisely regulating influencing factors, and selecting efficient biofilm formation methods.

I. Efficient Strategies Based on Biofilm Formation Principles

Biofilm formation is essentially the process of microbial adsorption, proliferation, and the formation of a stable community on the carrier surface. Environmental regulation is needed to strengthen key links:

- Direct inoculation: Directly add high - concentration activated sludge (3000 - 5000 mg/L) or special compound bacterial agents (containing nitrifying bacteria, denitrifying bacteria, etc.) to quickly provide dominant microbial communities.

- Circulatory inoculation method: Introduce microorganisms from surrounding sewage treatment systems into the MBBR to accelerate the initial attachment of microorganisms to the carrier surface.

- Precise nutrient supply: Supplement carbon sources (such as glucose), nitrogen fertilizers (urea), and phosphorus fertilizers according to the ratio of BOD₅:N:P = 100:5:1 to avoid inhibiting microbial activity due to nutrient imbalance. Add trace elements (such as iron and manganese) in the initial stage to enhance microbial metabolic capacity.

II. Dynamic Regulation of Core Influencing Factors

- Environmental parameter optimization

- Temperature control: Maintain a constant temperature environment of 20 - 30°C. Use heating devices at low temperatures to prevent the slowdown of microbial metabolism.

- Dissolved oxygen (DO) management: Keep the DO at 2 - 3 mg/L in the initial stage to reduce water flow scouring. After the biofilm is initially formed, increase it to 3 - 4 mg/L to promote the growth of aerobic microorganisms.

- pH stabilization: Control the pH at 6.5 - 8.5 with acid - base regulators to prevent extreme pH values from damaging microbial activity.

- Carrier performance enhancement

- Surface modification: Use physical methods such as sandblasting and acid etching to increase the roughness of the carriers, or apply chemical coatings (such as hydrophilic polymer materials) to enhance the microbial attachment ability.

III. Combined Application of Efficient Biofilm Formation Methods

| Method | Operation Key Points | Advantages | Applicable Scenarios |

| Sludge discharge inoculation method + flow rate increment | After adding high - quality activated sludge, start at 30% of the design load and increase the influent flow rate by 10% every 2 - 3 days to avoid excessive scouring of the biofilm | Fast startup + stable biofilm formation, reducing the risk of detachment | Newly - built systems with high requirements for startup time |

| Intermittent aeration method + nutrient enhancement | Alternate aeration for 4 hours and stop aeration for 2 hours, and simultaneously increase the carbon source addition amount to promote the coordinated growth of anaerobic/aerobic microbial communities | Accelerate biofilm maturation and improve pollutant degradation ability | Industrial wastewater treatment systems dealing with complex pollutants |

| Composite biofilm formation method | Combine surface - modified carriers + special bacterial agents + step - by - step load operation to comprehensively improve the biofilm formation efficiency | Minimize the biofilm formation cycle and ensure membrane stability | High - concentration organic wastewater treatment systems |

IV. Process Monitoring and Emergency Adjustment

- Real - time monitoring: Daily detect COD, ammonia nitrogen, and biofilm thickness (target value 100 - 300 μm). Observe the color change of the carriers (transparent → light yellow → dark brown) to judge the biofilm formation process.

- Abnormality handling: If biofilm formation is slow, additional carbon sources can be added or the aeration - stopping time can be extended. When biofilm detachment occurs, reduce the aeration volume and flow velocity. If necessary, replace some aged carriers.

Through the above multi - dimensional coordinated strategies, the MBBR biofilm formation cycle can be shortened from the conventional 2 - 3 weeks to 7 - 10 days, significantly improving the system startup efficiency and operation stability. Juntai provides technical support for sewage treatment projects to achieve effectiveness quickly.