+86 13600513715

+86 13600513715 MBBR for Textile Dyeing Wastewater Treatment: Efficiency Meets Sustainability

Why Textile Wastewater Poses Unique Challenges

Textile dyeing wastewater ranks among the world’s most polluted industrial effluents. It contains:

-

Complex organic compounds (Azo dyes, phenols, PVA)

-

High salinity (Up to 15% TDS from dye-fixing salts)

-

Toxic inhibitors (Heavy metals, formaldehyde, chlorinated solvents)

-

Extreme pH fluctuations (pH 2-12 from scouring/bleaching)

-

Variable hydraulic loads (Batch processing creates shock loads)

Conventional biological treatments like activated sludge frequently fail here. Sludge bulking, biomass toxicity, and poor nutrient removal plague plants – until Mbbr Technology enters the picture.

How Mbbr Wastewater Treatment Conquers Textile Effluents

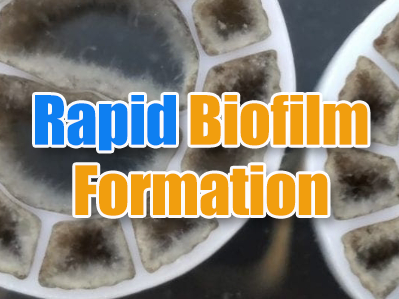

Core Mechanism: Biofilm Meets Mobility

The moving bed biofilm reactor (MBBR) process utilizes engineered plastic biofilm carriers (typically HDPE/PP) suspended in MBBR tanks. These carriers provide 500-1200 m²/m³ protected surface area for microbial colonization. As MBBR biofilm carriers fluidize via fine-bubble aeration, they create a self-renewing biological treatment system. Key mechanisms include:

-

Adsorption-Biodegradation Synergy: Toxic dyes first adsorb onto carrier surfaces, then undergo enzymatic breakdown by specialized biofilm consortia.

-

Simultaneous Nitrification/Denitrification: Aerobic zones (outer biofilm) convert NH₃→NO₃; anoxic micro-zones (inner biofilm) reduce NO₃→N₂.

-

Halotolerant Biomass: Biofilms develop salt-adapted microbes surviving >10% salinity – impossible in suspended-growth systems.

System Architecture: Modular & Multistage

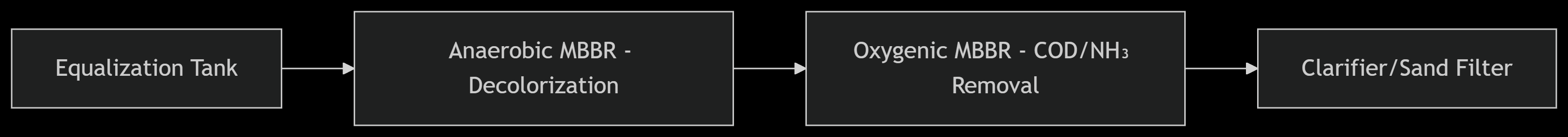

A full-scale MBBR system for wastewater treatment in dyeing plants typically integrates:

Note: Hybrid configurations (e.g., MBBR + activated sludge) boost resilience against shock loads.

5 Unmatched Advantages of MBBR in Textile Effluent Treatment

-

Extreme Toxicity Resistance

LEVAPOR® carrier trials show 95% Reactive Black 5 dye removal at concentrations lethal to activated sludge. The porous carriers adsorb inhibitors first, shielding biofilm microbes while degradation occurs. After acclimation, MBBR bioreactor communities develop dye-degrading enzymes (azoreductases, laccases) for sustained treatment. -

Zero Biological Washout During Flow Peaks

Unlike clarifier-dependent systems, MBBR in wastewater treatment retains biomass on carriers during 3X hydraulic surges – common in batch dyeing. No sludge recirculation needed! -

>90% COD Removal Under High Salinity

Studies confirm 10-14% NaCl minimally impacts MBBR performance once halophilic biofilms establish. Activated sludge collapses at >3% salinity. -

60% Less Sludge Production

The long SRT (20-40 days) of attached biomass minimizes excess sludge. Textile plants save ~$150/ton on sludge disposal costs. -

Modular Scalability

Need to double capacity? Simply add more MBBR filter media to existing tanks. No new concrete structures – ideal for space-constrained mills.

Real-World Performance: Data from Operational Systems

| Parameter | Influent (Textile WW) | MBBR Effluent | Removal Rate |

|---|---|---|---|

| COD (mg/L) | 850-2,200 | 45-75 | 95-97% |

| BOD₅ (mg/L) | 250-650 | 8-15 | >97% |

| NH₃-N (mg/L) | 28-52 | 0.8-2.1 | 94-98% |

| Color (Pt-Co) | 1,500-3,000 | 25-50 | >98% |

| TSS (mg/L) | 120-400 | 10-20 | >95% |

Data synthesized from full-scale textile MBBR plants in India, China & Turkey.

Optimizing MBBR for Dyeing Wastewater: Critical Design Parameters

-

Carrier Selection: High-porosity (>90%) PU or modified PE MBBR carrier media outperform conventional K1/K3 for macromolecular dyes. Fill ratio: 40-60%.

-

Anoxic Pre-Treatment: Use anaerobic MBBR for azo bond cleavage before aerobic polishing.

-

Retrofitting Existing Tanks: Convert aeration basins to MBBR tanks by adding carriers + sieve grids. CAPEX reduction: 40% vs. new builds.

-

Smart Aeration Control: DO maintained at 2.5-3.5 mg/L via VFD blowers. Prevents carrier clumping and over-oxidation of sensitive dyes.

Pro Tip: Pilot testing with site wastewater is non-negotiable! Biofilm acclimation takes 3-8 weeks but ensures predictable full-scale results.

Why Global Textile Giants Choose MBBR Over Alternatives

Compared to competing technologies:

| Technology | OPEX Reduction | Footprint | Color Removal | Salt Tolerance |

|---|---|---|---|---|

| MBBR | 35-50% | Compact | ★★★★☆ | ★★★★★ |

| Activated Sludge | Baseline | Large | ★★☆☆☆ | ★★☆☆☆ |

| Conventional MBR | 15-25% higher | Compact | ★★★★☆ | ★★★☆☆ |

| Electrocoagulation | 60-80% higher | Small | ★★★★★ | ★☆☆☆☆ |

MBBR leads in operational economy while handling complex, saline flows.

Future-Proofing Your Treatment Plant: MBBR + IoT

Next-gen MBBR wastewater treatment plants integrate:

-

Carrier-Tracking Sensors: Monitor biofilm thickness/activity in real time

-

AI-Powered Aeration: Dynamically adjust blowers based on ammonia/COD sensors

-

Predictive Clogging Alerts: Use pressure transducers on retention screens

These innovations cut operator costs by 30% while ensuring compliance with tightening regulations (e.g., ZDHC).

Conclusion: Transform Waste into Resource Safely & Profitably

MBBR technology delivers textile factories a triple win:

-

Compliance with zero liquid discharge (ZLD) mandates

-

ROI via 40% lower energy vs. MBR and 60% reduced sludge hauling

-

Reuse Potential – Treated water meets ISO 20760 standards for dye bath reuse

Ready to retrofit your facility? JUNTAI’s biofilm reactors for wastewater treatment feature anti-clogging carriers and 10-year warranties – engineered specifically for textile effluents.