+86 13600513715

+86 13600513715 MBBR-AAO vs Bardenpho Retrofit: TN Removal Performance & Comparison

MBBR-Based AAO vs. Bardenpho: Retrofit Performance Comparison

Overview

With governments worldwide continuously improving water environment policies and strengthening pollution control efforts, wastewater discharge standards are also being raised. For high emission standards, the key lies in meeting ammonia nitrogen and total nitrogen (TN) targets, which requires either capacity reduction/expansion or in-situ enhancement of secondary biological treatment units. Since most wastewater Treatment Plants (WWTPs) have limited space for expansion, in-situ enhancement technologies for biological treatment have become one of the most effective solutions.

Currently, most WWTPs employ activated sludge processes, including AAO (Anaerobic-Anoxic-Oxic) and its variants, oxidation ditches, SBR (Sequencing Batch Reactor) and its derivatives. However, these processes struggle to meet high emission standards consistently and stably, necessitating integration with other technologies to comply with increasingly stringent regulations. The Moving Bed Biofilm Reactor (MBBR) is one of the most suitable solutions.

The essence of MBBR technology lies in adding suspended carriers to the biological treatment unit, where attached biofilm forms on these carriers to enhance pollutant removal. This retrofit approach follows an "embedded" philosophy, preserving the original process configuration. Since the first large-scale MBBR project was successfully implemented at Wuxi Lucun WWTP, this technology has become one of the mainstream solutions for plant upgrades.

The core advantage of MBBR is its ability to efficiently host nitrifying bacteria, making it highly effective for ammonia nitrogen removal, whether for Grade 1A or even stricter standards. For TN removal, MBBR leverages its enhanced nitrification capability to reduce aerobic zone volume, expand the anoxic zone, and prolong hydraulic retention time (HRT) in the anoxic zone, thereby improving denitrification.

In conventional processes like AAO, TN removal relies entirely on recirculation. Higher effluent standards demand greater removal rates, leading to larger recirculation ratios and consequently higher energy and chemical consumption. While AAO can meet Grade 1A standards, it becomes inadequate for stricter TN limits. The Bardenpho process, a five-stage system, overcomes the recirculation limitation by adding a post-denitrification zone after the AAO process, significantly enhancing nitrogen removal. As TN discharge standards tighten, Bardenpho has demonstrated notable advantages.

Traditional Bardenpho, based on activated sludge, suffers from long process chains and large footprints. Due to less stringent effluent requirements in the past, its application was limited. However, the introduction of MBBR technology now enables in-situ implementation of MBBR-based Bardenpho processes within biological treatment units.

Upgrading with MBBR technology allows for the creation of an AAO process by adding a pre-anoxic zone, or a Bardenpho process by incorporating a post-anoxic zone.

This study examines a wastewater treatment plant in northern China, where both MBBR-enhanced AAO and Bardenpho processes (referred to as MBBR-AAO and MBBR-Bardenpho, respectively) were implemented for phased upgrades. A comparative analysis of their operational performance is conducted to provide insights for future plant retrofits.

Project Background

The first phase of this wastewater treatment plant was constructed and put into operation in 1997 with a treatment capacity of 80,000 m³/d. It employed the VIP process (Virginia Initiate Plant) and complied with the secondary discharge standards of the "Integrated Wastewater Discharge Standard" (GB 8978-1996). While the actual effluent quality generally met the Grade 1B standards of GB 18918-2002 except for TN and TP, the NH₄⁺-N concentration occasionally exceeded the secondary standards of GB 8978-1996 during winter operation (2-3 months) when influent temperature dropped below 13°C.

In 2010, the plant underwent upgrades to meet Grade 1A standards of GB 18918-2002 for ammonia nitrogen and organic matter. Conventional biological treatment would require expanding tank volumes, but no land was available around the plant, and the limited onsite space couldn't accommodate such expansion. Therefore, the upgrade focused on enhancing the existing biological tanks' treatment capacity. After evaluating various options, the MBBR process was ultimately selected. The retrofit involved:

- Increasing pre-anoxic zone volume

- Reducing aerobic zone volume

- Adding suspended carriers in partial aerobic zones to create MBBR zones for enhanced pollutant removal

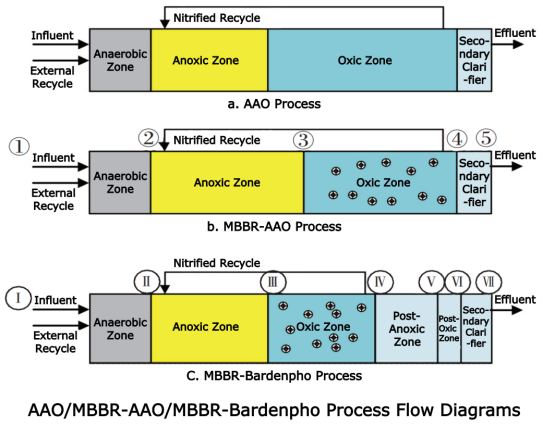

The specific process flow is shown in Figure 1(a) and (b).

In 2015, further upgrades were implemented to:

- Achieve comprehensive compliance with Grade 1A standards while maintaining potential to meet quasi-Class IV surface water standards

- Increase treatment capacity by 19% (from 80,000 to 95,000 m³/d) due to rapid regional economic development

Key challenges included:

- Stringent effluent requirements demanding superior treatment performance, especially in biological systems

- Capacity expansion without available land for construction

- TN removal requiring >82% efficiency - conventional approaches would need 500% recirculation ratio, causing high energy consumption and carbon source waste in anoxic zones due to excessive DO carryover

- After technical evaluation, the MBBR-Bardenpho process was adopted. Modifications included:

- Converting part of the aerobic zone into post-anoxic and post-aerobic zones to ensure TN compliance

- Further reducing aerobic volume while expanding suspended carrier zones

- Adding carriers with higher effective specific surface area to enhance ammonia removal

The retrofit scheme is illustrated in Figure 1(b) and (c).

Performance Analysis

The MBBR-enhanced AAO and Bardenpho processes were implemented in sequential upgrades at the same WWTP, with one-year operational data analyzed for each process. Since most conventional pollutants (except SS and TP) are primarily removed in biological tanks, this study focused on COD, NH₄⁺-N, and TN removal efficiencies.

① COD Removal Performance

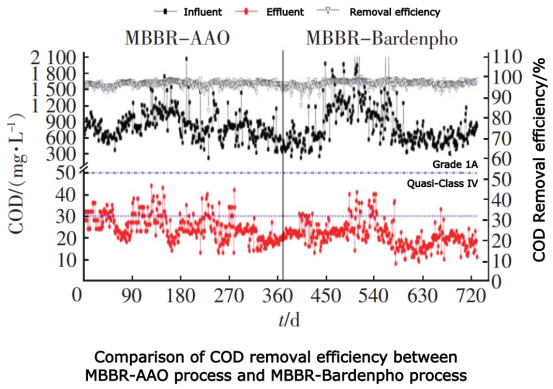

Figure 2 shows COD removal in both processes. Key observations:

- Influent COD:

MBBR-AAO: 821.1 ± 244.9 mg/L

MBBR-Bardenpho: 814.8 ± 414.4 mg/L

- Effluent COD:

MBBR-AAO: 25.1 ± 6.1 mg/L

MBBR-Bardenpho: 21.1 ± 5.7 mg/L

Both consistently met Grade 1A standards, with occasional compliance with quasi-Class IV surface water criteria. The MBBR-Bardenpho process demonstrated superior stability despite wider influent fluctuations, highlighting its resilience to organic load shocks.

Mechanisms:

- The alternating anoxic/aerobic zones in MBBR-Bardenpho promoted co-metabolism, enhancing degradation of complex organics (e.g., polycyclic compounds, halogenated hydrocarbons).

- Extended anoxic HRT improved slow-carbon-source utilization.

② NH₄⁺-N Removal Performance

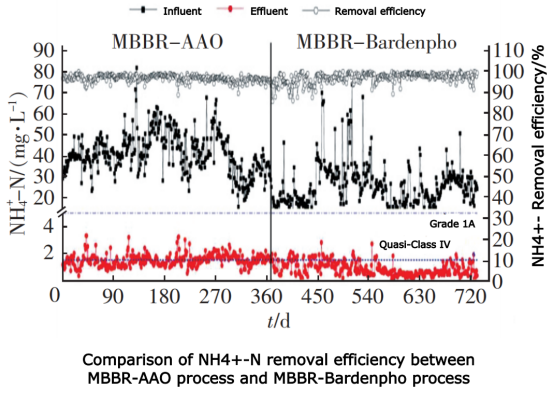

As shown in Figure 3:

- Effluent NH₄⁺-N:

MBBR-AAO: 1.5 ± 0.5 mg/L

MBBR-Bardenpho: 1.1 ± 0.9 mg/L

Both met Grade 1A standards, despite MBBR-Bardenpho handling 1.3× higher nitrogen loads due to increased flow and reduced aerobic volume.

Key Comparisons:

- Aerobic HRT: Reduced by 37% (13.6 h → 8.6 h) in Bardenpho.

- Nitrification Capacity:

MBBR-AAO: 0.158 kg/(m³·d)

MBBR-Bardenpho: 0.208 kg/(m³·d) (+32%)

MBBR Advantages:

- Biofilm on carriers retained nitrifiers with SRT >30 days, enabling high-efficiency enrichment.

- Carrier-mediated nitrification became dominant under low-temperature/shock loads.

- Design Flexibility: Ammonia removal scaled with total effective surface area, achieved by:

(a) Higher carrier fill ratio

(b) SPR-3 carriers (800 m²/m³ specific surface)

③ TN Removal Performance

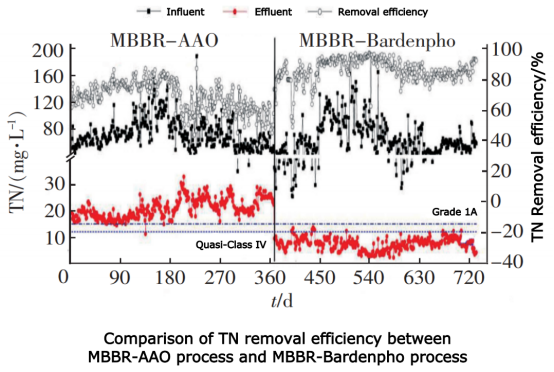

Figure 4 illustrates:

- Influent TN:

MBBR-AAO: 73.2 ± 22.0 mg/L

MBBR-Bardenpho: 65.9 ± 30.0 mg/L

- Effluent TN:

MBBR-AAO: 20.9 ± 3.8 mg/L (71.4% removal)

MBBR-Bardenpho: 7.4 ± 2.3 mg/L (88.8% removal)

Process Limitations:

- AAO: Reliant on recirculation (350–400% ratio), max theoretical removal: 80%. Achieving >85% removal would require unsustainable energy/carbon costs.

- Bardenpho: Post-anoxic zone overcame recirculation limits, boosting removal by 17.4% without increasing recirculation.

Design Impact:

- AAO (3-stage): Limited by single anoxic zone.

- Bardenpho (5-stage): Additional post-anoxic zone extended denitrification time and carbon utilization.

Economic Analysis

Land Use

- Bardenpho Process: 0.136 m²/(m³·d⁻¹), 16% more compactthan AAO [0.162 m²/(m³·d⁻¹)].

- Key Advantage: MBBR-enhanced systems achieve in-tank capacity expansionwithout additional land.

- New Plants: MBBR reduces footprint by 80–90%compared to conventional activated sludge (CAS), especially in pure MBBR designs (no secondary clarifiers/sludge return systems).

Energy Consumption

- AAO: 0.338 kWh/m³

- Bardenpho: 0.445 kWh/m³ (+0.107 kWh/m³)

- Causes: Higher nitrogen loads + stricter effluent standards.

- Note: Both values exceed typical WWTPs due tohigh influent COD (950 mg/L) and TN (80 mg/L), frequently exceeding design limits.

Chemical Usage

- Carbon Source: 25% sodium acetate solution, average 15 tons/day.

- Dosing ratio (pre-/post-anoxic zones): 1:2

- Adjustments: Pre-anoxic dosing pauses during organic shock loads.

Process Characteristics and Applicability

A comparative analysis of MBBR-enhanced AAO and Bardenpho processes is presented below, focusing on key performance and operational aspects:

① Treatment Efficiency

- Both MBBR-AAOand MBBR-Bardenpho demonstrate robust pollutant removal.

- TN Removal Advantage: MBBR-Bardenpho excels, achieving effluent TN <12 mg/L(or lower), making it suitable for stringent standards.

② Footprint Requirements

- Compact Design: Leveraging MBBR’s enhanced nitrification, both processes significantly reduce land use while enabling capacity expansion.

- Retrofit Compatibility: Existing tanks can be upgraded without structural modifications.

③ Operational Control

- MBBR-AAO:

- TN removal relies on high recirculation ratios, increasing energy costs.

- Challenging to fine-tune for optimal TN removal.

- MBBR-Bardenpho:

- Adjusts internal recirculation based on influent BOD, reducing flow rates.

- Post-anoxic zoneenables precise TN control via carbon dosing, enhancing operational flexibility.

| Process Selection Guidelines | ||

| Criteria | MBBR-AAO | MBBR-Bardenpho |

| Criteria | MBBR-AAO | MBBR-Bardenpho |

| Configuration | 3-stage (shorter process) | 5-stage (extended process) |

| Ammonia Removal | Excellent | Excellent |

| TN Removal | Moderate (requires high recirculation) | Superior (via post-anoxic denitrification) |

| Energy Demand | Higher (recirculation-dependent) | Lower (optimized recirculation) |

| Best For | Grade 1A standards | Grade 1A or stricter (e.g., quasi-Class IV) |

| Medium-strength influent | High TN removal requirements | |

Key Takeaways:

- MBBR-AAO: Simpler operation, suited for conventional Grade 1A compliance.

- MBBR-Bardenpho: Preferred for ultra-low TN targets, offering dosing-controlled precision.

Conclusions

- MBBR-based Upgrades:

- Both MBBR-AAOand MBBR-Bardenpho processes achieve stable NH₄⁺-N and COD removal, meeting Grade 1A and even quasi-Class IV surface water standards.

- Nitrification capacity:

- MBBR-AAO: 158 kg/(m³·d)

- MBBR-Bardenpho: 208 kg/(m³·d) (32% higher)

- MBBR-Bardenphodemonstrates superior effluent stability and shock-load resistance.

- TN Removal Superiority of MBBR-Bardenpho:

- Ensures effluent TN <12 mg/Lvia post-anoxic zone enhancement, achieving 8% TN removal in the biological stage.

- Microbial Community Insights:

- Biofilm on carriers: Enriches nitrifying bacteria (>10% relative abundance), securing stable nitrification.

- Activated sludge: Hosts higher denitrifier abundance, enabling efficient TN removal.

- Synergy: Carriers and sludge jointly ensure NH₄⁺-N and TN compliance.

- Process Applicability:

- MBBR-AAO:

- Compact retrofits, but TN removal limitedby recirculation dependence.

- Best forGrade 1A compliance with medium-strength influent.

- MBBR-Bardenpho:

- Land-efficientwith unmatched TN removal.

- Ideal for quasi-Class IV/+ standardsand high-nitrogen influent.