+86 13600513715

+86 13600513715 Land-based Recirculating Aquaculture System (RAS) Process Technology

Overview

The land-based industrialized RAS model is characterized by:

- Minimal environmental discharge– Little to no release of nutrient-rich pollutants

- Water reuse– Repeated recycling and treatment of water, minimizing external contamination

Core Technology: Water Purification

Treatment stages

- Source water treatment

- In-system water treatment

- Necessary effluent treatment

Key Water Treatment Technologies

- Mechanical filtration

- Foam fractionation (protein skimming)

- Biological purification

- Oxygenation

- UV sterilization

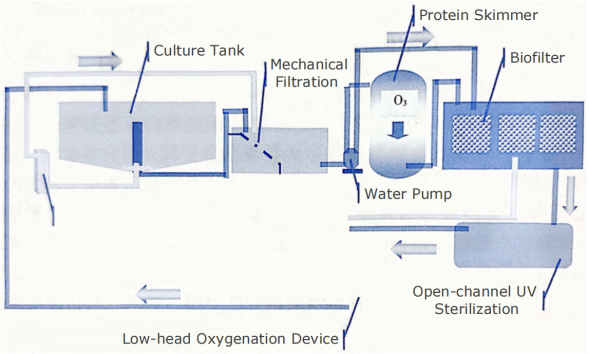

Water Treatment Process Flow

- Effluent from fish tanksfirst passes through a Drum Filter (mechanical screen) to remove suspended solids (mainly uneaten feed, feces, and detached biofilm).

- Protein skimmer eliminates dissolved organic matter (e.g., proteins) and colloidal particles.

- Biofilteremploys microbial nitrification to remove toxic ammonia and nitrite.

- UV sterilizationdisinfects the water.

- Oxygenation(via pure oxygen or air injection) ensures optimal dissolved oxygen levels.

- Treated water recirculates back to the fish tanks, forming a closed-loop system(summarized as: "Single lift, dual filtration, partial disinfection, thorough purification").

Water treatment technology

Water purification is the cornerstone of closed-loop RAS operation, integrating principles and technologies from water treatment, biology, and microbiology. The core objective of RAS water treatment is to remove harmful pollutants while maintaining optimal water quality parameters such as temperature, dissolved oxygen (DO), and pH.

RAS Water Treatment Methods by Mechanism

RAS treatment processes are broadly categorized into three main approaches:

- Biological Methods

- Activated sludge process

- Biofilm systems (e.g., Moving Bed Biofilm reactors - MBBR)

- Biological fluidized beds

- Physical Methods

- Activated carbon adsorption

- Foam fractionation (protein skimming)

- Chemical Methods

- Ozonation

- Photocatalytic oxidation

- Electrochemical oxidation

Case Study: Atlantic Salmon RAS at Oriental Ocean

In the closed-cycle Atlantic salmon farming project, the RAS system combines multiple advanced treatment technologies tailored to:

- Nutrient requirements & metabolic waste profiles

- Effluent characteristics & loading rates

- Water quality demands of cultured species

- Biofilter performance criteria

Integrated Treatment Technologies Applied:

- Solid-liquid separation(mechanical filtration)

- Foam fractionation(protein removal)

- Biological filtration (nitrification/denitrification)

- Ozone treatment(disinfection & oxidation)

- UV sterilization(pathogen control)

- Oxygenation systems(DO management)

The following sections detail each of these water treatment technologies.

- Solid-liquid Separation Technique

Solid-liquid separation technology primarily targets the removal of suspended solid particles from aquaculture wastewater. Based on particle characteristics (density, size) and separation methods, it can be categorized into:

- Mechanical filtration:

Example: Curved screen filters intercept particles >30μm with >95% removal efficiency.

- Gravity separation:

Settling tanks or hydrocyclones for denser particles.

- Foam Fractionation

A flotation-based technique widely used in marine RAS due to seawater’s high surface tension, which facilitates foam generation via aeration. In freshwater systems, it is only applied when organic loads are high.

- Ozone-enhanced operation:

Ozone is often injected into the air supply for simultaneous disinfection and color removal.

- Biofiltration Technology

The core of RAS water treatment, biofiltration employs biofilm-based bioreactors (e.g., MBBR) due to their:

- High treatment efficiency

- Compact footprint

- Low construction/operational costs

- Strong shock-load resistance

Mechanisms:

- Microbial oxidation & flocculation

- Adsorption by filter media

- Food chain predation in microbial ecosystems

Advantages over activated sludge:

- Better supports nitrifying bacteriagrowth for aquaculture.

- Widely studied in nitrogen removal optimization, with preliminary quantitative design parameters from EU/US research

| Design Parameters | Design Reference Values |

| Total Ammonia Nitrogen (TAN)Production Rate of Fish | 3% of daily baiting rate |

| Maximum Allowable Unionized Ammonia(UIA-N)Concentration for Fish | 0.025 mg/L |

| Maximum Allowable Total Ammonia Nitrogen (TAN) for Fish | 1.0 mg/L |

| Ammonia Removal Rate of Biofilter | 200-600 mg/(m2·d) |

| Oxygen Demand to Total Ammonia NitrogenRatio(O2:TAN) | 4.18-4.57 |

- Ozonation Technology

Ozone effectively oxidizes and breaks down organic matter and toxic metabolites. Post-treatment water achieves oxygen supersaturation while offering rapid action, zero secondary pollution, and excellent decolorization. Widely adopted in marine aquaculture and effluent treatment, ozone is typically injected into foam fractionators in RAS systems.

- UV Disinfection Technology

Ultraviolet (UV) radiation is extensively used in both freshwater and marine aquaculture to eliminate pathogens, offering low operational costs and no toxic residuals. A properly maintained UV system achieves >99% inactivation rate for Vibrio spp.

- Oxygen-Addition Technique

Pure oxygen injection elevates dissolved oxygen (DO) at inlet points to 110% saturation, while production tanks maintain 80–90% saturation. Critical considerations:

- Balance oxygen supply with species requirements

- Avoid oxygen narcosis("drunkenness" effect from hyperoxia)