+86 13600513715

+86 13600513715 Industrial Recirculating Aquaculture Water Treatment Technology Models

Model Overview

Industrial recirculating aquaculture, also known as closed-system aquaculture, is characterized by the recycling of water discharged from culture tanks after treatment. Water Treatment is the core and key to efficient recirculating aquaculture. The standard treatment process typically includes sedimentation, filtration, biological purification, oxygenation, temperature adjustment, sterilization, and disinfection before the water is reintroduced into the culture tanks for reuse. A portion of the tailwater is treated to meet discharge standards before being released.

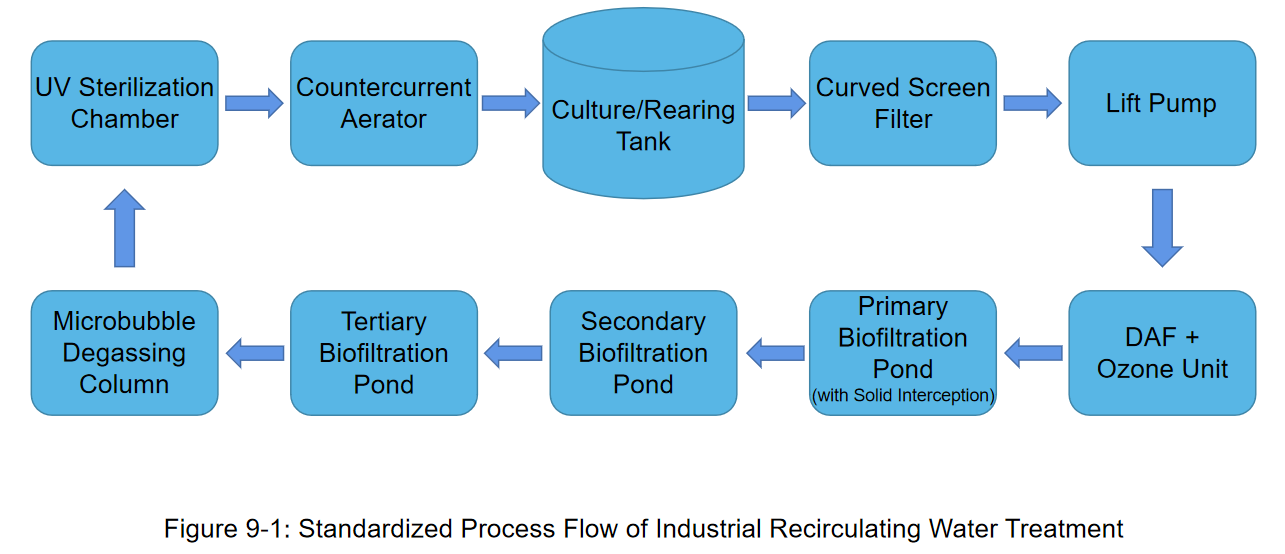

This treatment model employs physical, chemical, and biological filtration, along with a series of processes such as microscreen filtration, curved screen filtration, foam fractionation, biological purification, sterilization, degassing, and oxygenation (Figure 9-1). It removes or converts harmful solids, suspended particles, soluble substances, and gases from the water while replenishing dissolved oxygen, enabling full or partial water reuse. This technology supports high-density aquaculture and year-round, off-season production.

The industrial recirculating aquaculture model offers several advantages:

- Space-efficient with high stocking densities.

- Water- and energy-saving, highly efficient.

- Controllable production parameters, enabling chemical-free farming.

- Sustainable and eco-friendly, significantly reducing environmental pollution through compliant tailwater discharge.

- Integrates modern industrial technologies, including engineering, biotechnology, water treatment equipment, and smart systems, transforming aquaculture from traditional farming to industrialized production—a critical pathway for modernizing China’s fisheries.

However, this model also has challenges, such as high initial investment, elevated operational costs, and stringent technical and management requirements. Currently, China’s industrial recirculating aquaculture covers over 2 million m², supporting key species like fish, shrimp, sea cucumbers, and shellfish, with vast growth potential.

Technical Principles

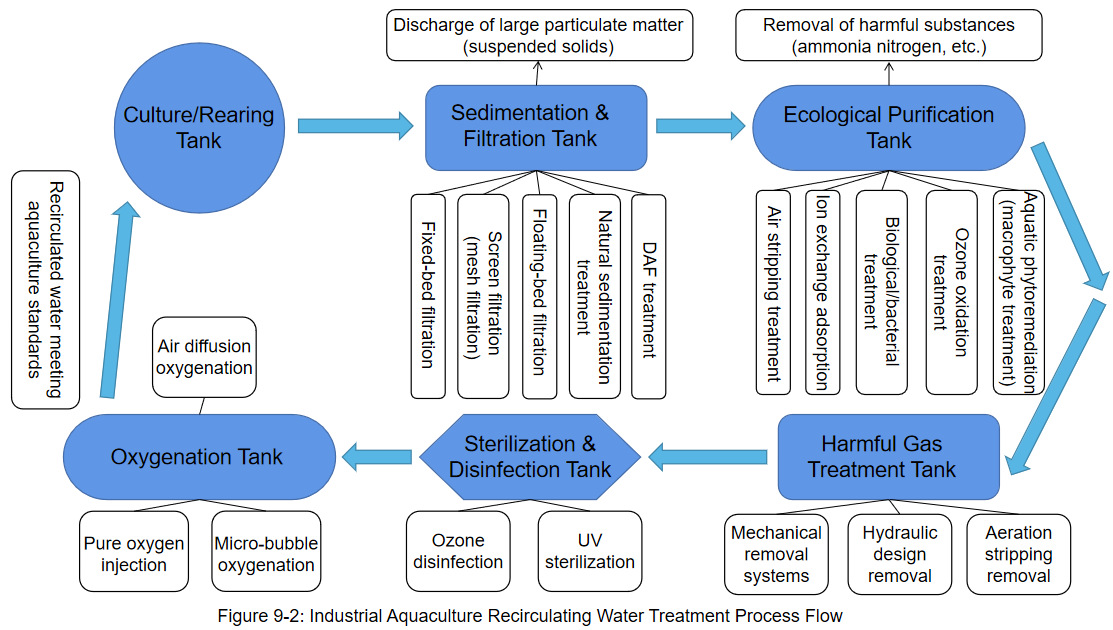

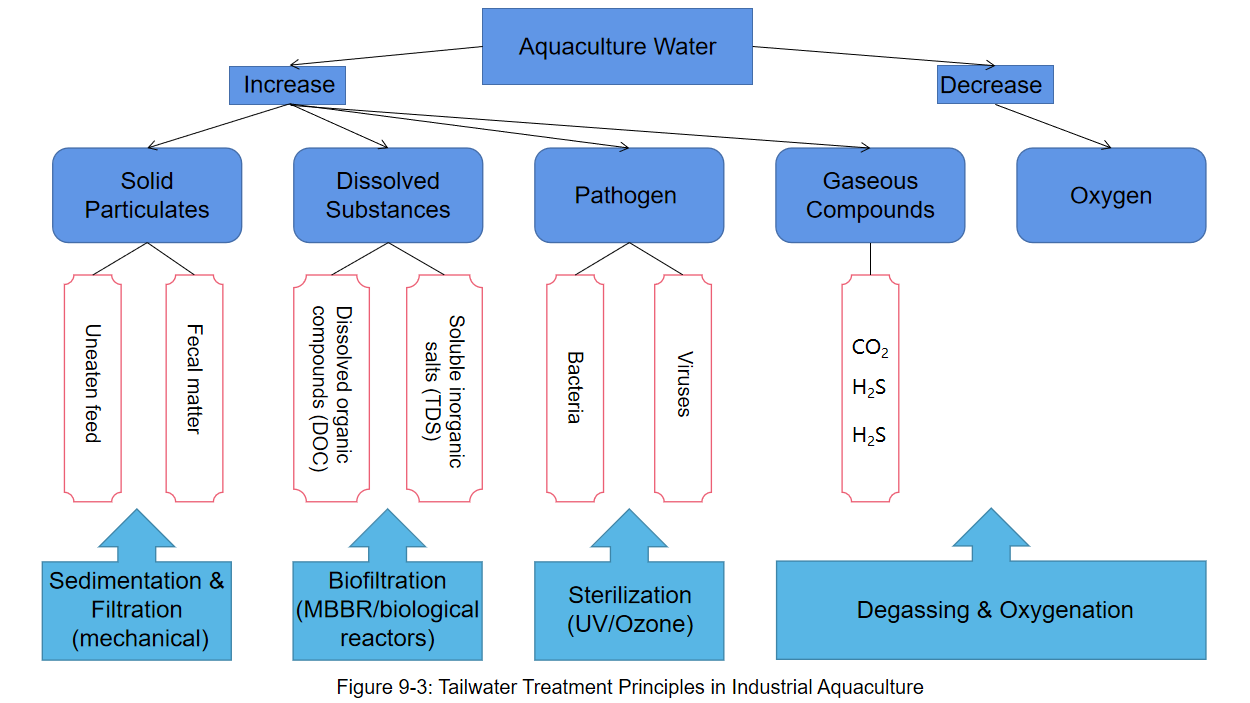

The core of industrial recirculating water treatment is to maintain an optimal ecological environment for aquatic species. Tailwater contains solids, soluble substances, pathogens, and gases, and the treatment aims to promptly remove pollutants like metabolic waste and residual feed. Key technologies include (Figure 9-2):

- Suspended Solids Removal

- Methods: Sedimentation, microscreen filtration, media filtration, foam fractionation.

- Soluble Pollutants Removal

- Methods: Biofilm treatment, ozone oxidation.

- Sterilization & Oxygenation

- Pathogen control: UV or ozone disinfection.

- Oxygen management: Aeration, high-efficiency oxygen dissolution, and degassing (to remove CO₂, H₂S, NH₃) (Figure 9-3).

If you want more details, feel free to contact cheemurai@juntaiplastic.com, whatsapp/wechat:+86-13247137344.:)