+86 13600513715

+86 13600513715 ICEAS Process & CAST Process

ICEAS Process

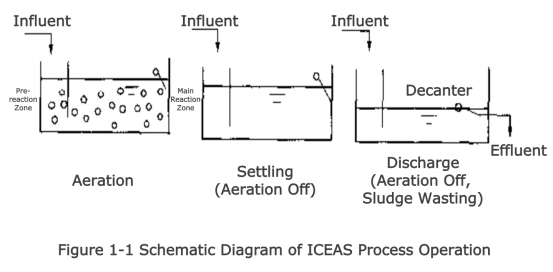

ICEAS stands for Intermittent Cyclic Extended Aeration System. Known as the Intermittent Cyclic Extended Sludge Activated Sludge Process in Chinese, it is a modified SBR (Sequencing Batch Reactor) technology featuring continuous inflow and periodic drainage. The basic process flow is illustrated in Figure 1-1.

Key Features of ICEAS Technology

- Sedimentation Characteristics

- Unlike classical SBR (ideal sedimentation), ICEAS experiences disturbed sedimentationdue to continuous inflow.

- To minimize inflow turbulence, ICEAS tanks are typically rectangular, with inflow/outflow at opposite ends (similar to a horizontal-flow sedimentation tank).

- Aspect ratio (L:W) = 2:1 to 4:1to prevent excessive horizontal velocity and sludge accumulation near the outlet.

- Hydraulic Regime & Organic Removal

- Continuous inflow compromises the ideal plug-flow advantageof classical SBR, limiting efficiency for refractory organic degradation.

- Flow regime approaches complete-mix, reducing sludge bulking control. Thus, ICEAS requires a selector zone(anoxic/anaerobic) to suppress filamentous bacteria.

- Operational Simplicity

- No frequent valve switching(vs. classical SBR), making it suitable for large-scale plants.

- Cycle Design & Limitations

- Cycle time: 4–6 hours (two tanks alternating operation).

- Shared infrastructure: Aeration/drainage equipment sized for 50% of total capacity(single-tank demand).

- Low utilization rates:

- Aerated/non-aerated phase ratio = 1:1(reduces tank/equipment efficiency).

Cyclic Activated Sludge Technology (CAST)

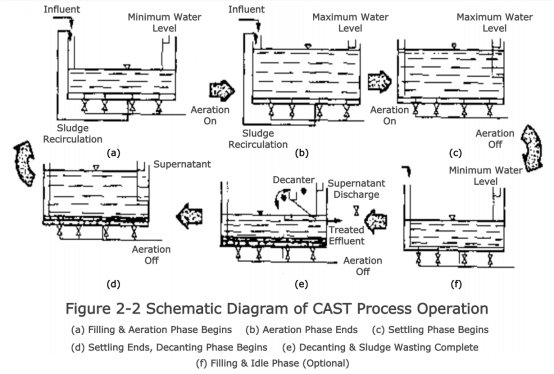

The Cyclic Activated Sludge Technology (CAST) is an advanced variation of the SBR (Sequencing Batch Reactor) process. Also known as CASS (Cyclic Activated Sludge System) or CASP (Cyclic Activated Sludge Process), CAST evolved from the ICEAS (Intermittent Cyclic Extended Aeration System) process. Compared to ICEAS, CAST features a smaller pre-reaction zone that is optimized into a more efficient biological selector.

The defining characteristic of CAST is the recirculation of return activated sludge (RAS) from the main reaction zone to the selector, with no inflow during the settling phase, ensuring stable effluent quality. A standard CAST system consists of three compartments:

- Biological selector (high-load zone)

- Anoxic zone

- Aerobic zone

The typical volume ratio of these zones is 1:5:30. The basic process flow is illustrated in Figure 1-2.

Key Features of CAST Technology

- Enhanced Sludge Selector for Bulking Control

- The biological selector(high F/M ratio) promotes floc-forming bacteria growth while suppressing filamentous bacteria, preventing sludge bulking even under variable inflow conditions.

- Rapid removal of soluble biodegradable organicsoccurs in the selector.

- Superior Sludge-Water Separation

- Mixed liquor concentration during peak water levels matches conventional activated sludge systems.

- Full-volume settling(no inflow disturbance) improves clarification efficiency.

- Microbial flocculation during aeration termination enhances sedimentation.

- Variable Water Level Operation

Water level cyclically fluctuates between minimum and maximum design levels, improving adaptability to flow/load variations.

- Efficient Nutrient Removal

- Simultaneousnitrification-denitrification: Controlled aeration enables nitrification, while anoxic periods in the sludge bed facilitate denitrification.

- Phosphorus removal: Polyphosphate-accumulating organisms (PAOs) thrive via aerobic/anaerobic cycling, with excess sludge withdrawal ensuring P elimination.

- Series Reactor Configuration

- Multiple tanks operate in series, achieving plug-flow dynamicsdespite individual complete-mix reactors.

- Enhances treatment stability and volumetric efficiency.

- Cost & Space Savings

- No primary/secondary clarifiers

- Low 20% sludge recirculation ratio(vs. 50–100% in conventional AS).

- Compact modular design simplifies expansion.