+86 13600513715

+86 13600513715 How to choose the biological filtration unit for land-based RAS

1. Introduction

Biofiltration is a critical component in land-based Recirculating Aquaculture Systems (RAS), responsible for removing toxic nitrogenous wastes (ammonia and nitrite) and maintaining optimal water quality. The choice of biofiltration technology significantly impacts system efficiency, operational costs, and fish health. This article provides a comprehensive guide to selecting the most suitable biofiltration unit based on system load, space constraints, energy consumption, and species requirements.

2. Comparison of Biofiltration Technologies

| Type | MBBR | Biofilter (Fixed Bed) | Fluidized Bed | Trickling Filter |

| Principle | Suspended biofilm carriers | Fixed media (e.g., ceramic rings) | Fluidized particles (e.g., sand) | Gravity-driven water flow |

| Surface Area | 500–1200 m²/m³ | 200–400 m²/m³ | 3000–5000 m²/m³ | 100–300 m²/m³ |

| Ammonia Removal | 85–95% | 70–85% | 90–98% | 60–75% |

| Energy Use | Medium (aeration) | Low | High (fluidization) | Very low |

| Best For | High-density fish/shrimp | Medium-load systems | Ultra-high load (e.g., salmon) | Small-scale systems |

3. Key Selection Criteria

3.1 Ammonia Loading Rate

Low load (e.g., shrimp, juveniles): Trickling filter or fixed-bed biofilter.

High load (e.g., salmon, seabass): MBBR or fluidized bed.

3.2 Space Constraints

Limited space: MBBR (stackable) > Fluidized bed > Fixed-bed.

Large facilities: Multi-stage fixed-bed biofilters (cost-efficient).

3.3 Energy Efficiency

Lowest energy: Trickling filter (gravity-fed) > RBC > Fixed-bed > MBBR > Fluidized bed (highest energy).

3.4 Startup Time

Fastest: Fluidized bed (3-5 days) > MBBR (7-14 days) > Fixed-bed (3-4 weeks).

3.5 Salinity Tolerance

Freshwater: All biofilters perform well.

Marine RAS: MBBR with salt-tolerant biofilm carriers preferred.

4. Design & Operational Considerations

4.1 Hydraulic Retention Time (HRT)

| Biofilter Type | Typical HRT (hrs) |

| MBBR | 4-6 |

| Fixed-bed | 6-8 |

| Fluidized bed | 2-4 |

| Trickling filter | 1-2 |

4.2 Oxygen Requirements

Nitrification consumes 4.3 mg O₂ per mg NH₃-N oxidized.

MBBR: DO ≥ 4 mg/L, aeration rate ~0.3-0.5 m³ air/kg carriers/h.

4.3 Temperature Effects

Optimal range: 20-30°C.

Below 15°C: Nitrification slows by 50% (requires longer HRT or heating).

4.4 pH & Alkalinity Management

Nitrification consumes alkalinity (7.14 mg CaCO₃ per mg NH₃-N).

Maintain pH 7.0-8.5 (add sodium bicarbonate if needed).

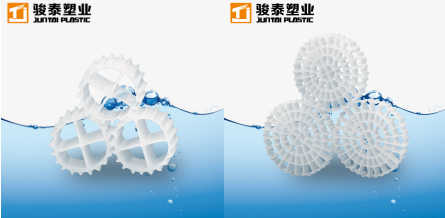

Juntai MBBR04(K1) & MBBR64(K5)

5. Recommended System Configurations

5.1 High-Density Fish RAS (e.g., Salmon)

Process: Drum Filter → MBBR → Denitrification reactor → UV/Ozone.

Performance: Ammonia <0.5 mg/L, nitrate <50 mg/L.

5.2 Shrimp RAS

Process: Protein skimmer → Fluidized bed → Fixed-bed biofilter.

Advantage: Handles organic surges from feeding.

5.3 Low-Cost Hatchery System

Process: Screen filter → Trickling filter → Fixed-bed biofilter.

Cost: 40% cheaper than MBBR-based systems.

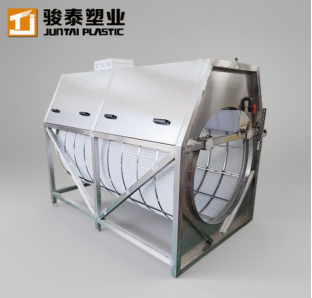

JUNTAI MBBR64S

6. Common Mistakes & Solutions

❌ Mistake: Using ultra-high-surface-area media (e.g., micro-sand) without proper flow control.

✅ Solution: Optimize carrier fill ratio (40-60% for MBBR).

❌ Mistake: Ignoring denitrification (nitrate buildup >100 mg/L).

✅ Solution: Add methanol/ethanol in an anoxic reactor or sulfur-based denitrification.

❌ Mistake: Placing biofilter before solids removal.

✅ Solution: Always use mechanical filtration (drum filter) first.

7. Future Trends

Smart biofilters: IoT-controlled aeration based on real-time ammonia sensors.

Hybrid carriers: Conductive/biocatalytic media for enhanced denitrification.

Modular designs: Plug-and-play biofilter units for easy scaling.

8. Conclusion

The optimal biofiltration unit depends on:

✔ Ammonia load (MBBR for high, fixed-bed for medium).

✔ Space & energy constraints (MBBR compact, trickling filter low-energy).

✔ Species requirements (salmon need high-efficiency fluidized beds).

For most RAS applications, MBBR offers the best balance of performance and scalability, while fluidized beds excel in extreme high-load systems. Pilot testing is recommended before full-scale implementation.

This structured guide ensures informed decision-making for RAS biofiltration selection, optimizing both economic and operational efficiency.