+86 13600513715

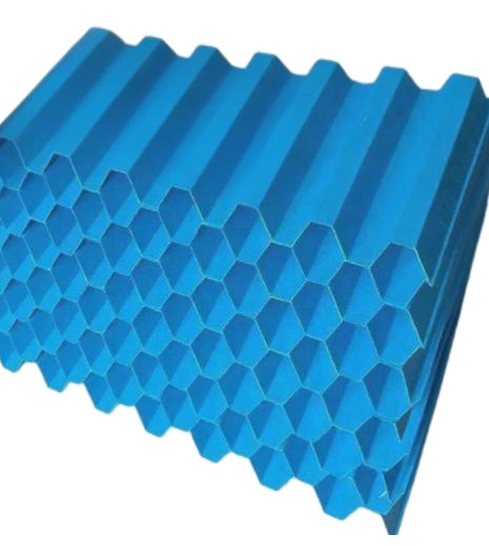

+86 13600513715 How to Assemble PVC Tube Settler Securely & Key Precautions

Analysis of PVC Inclined Pipe Connection Methods

It is not recommended to use a heat gun for hot-melt connection of PVC inclined pipes. The core reasons are related to the characteristics of PVC materials and the adaptability of hot-melt processes, as detailed below:

I. PVC materials are not suitable for traditional hot-melt welding

PVC (polyvinyl chloride) has poor thermal stability. When heated above 160°C, it will decompose, releasing toxic gases such as hydrogen chloride (HCl). At the same time, the material itself will become brittle and degrade, leading to a significant decrease in the strength of the connected parts and even cracks. Traditional hot-melt welding (such as the process used for PPR and PE pipes) requires heating the material to a molten state (usually above 180°C), which directly destroys the molecular structure of PVC, causing interface embrittlement and seal failure. Its connection effect is rather less reliable than that of special glue.

II. The essence of PVC "welding" is solvent fusion

The "welding" of PVC in the industry does not refer to high-temperature hot melting, but is achieved through special PVC adhesives (solvent-based). The solvent contained in such adhesives can dissolve the surface of PVC, allowing the material molecules on both sides of the interface to penetrate and fuse with each other. After cooling, an integral connection is formed, which is essentially "chemical fusion" rather than "physical hot melting". This method does not require high temperatures, can avoid PVC degradation, and is a standard connection process for PVC pipes (including inclined pipes), with its strength and sealing performance verified by practice.

However, the firmness of glue connection for PVC inclined pipes depends on the type of glue, construction technology and service environment, and is relatively reliable under appropriate conditions. The specific points are as follows:

1. The applicability of glue is crucial

It is necessary to use special PVC adhesives (usually solvent-based, which achieve the "welding" effect by dissolving the surface of PVC) instead of ordinary all-purpose adhesives. This type of glue can melt and fuse the surface of PVC pipes, forming a molecular-level connection with much higher strength than physical adhesion. If non-special glue (such as epoxy resin glue, instant glue, etc.) is used by mistake, it can only be fixed by surface viscosity, which is easy to fall off due to thermal expansion and contraction or stress of PVC, and the firmness is extremely poor.

2. Construction technology directly affects firmness

Surface treatment: Before connection, it is necessary to polish the interface surface of the PVC inclined pipe with sandpaper to remove oil, dust and oxide layer, so as to ensure that the glue can fully infiltrate the surface of the pipe and improve the fusion effect.

Gluing and curing: Apply glue evenly on both sides of the interface (not too thick or too thin). Wait a few seconds for the solvent to volatilize slightly, then butt joint quickly, and fix with a fixture until fully cured (usually 24 hours, which needs to be extended in low-temperature environment). Avoid stress or water during curing, otherwise it is easy to cause interface cracking.

Interface form: If the inclined pipe interface is a flat butt joint, it is recommended to increase the lap length o ruse flanges for auxiliary fixing; if it is a socket interface, it is necessary to ensure sufficient socket depth to increase the contact area and enhance firmness.

3.Limitations of the service environment

Temperature range: PVC adhesives have stable performance in the environmentof-10℃~60℃. If the temperature is too high(such as long-term exceeding 60℃), it may lead to accelerated aging of theglueanddecreased interface strength; the curing speed becomes slow at low temperatures, requiring longer time for fixing.

Pressure and stress: PVC inclined pipes are usually used ingravity flow scenarios(such as sedimentation tanks, filter tanks). If used in pressure-bearing pipelines (such as conveying pressure water), the simple glue connection may not be able to bear the pressure, and other reinforcement methods (such as bolt flanges)need to be used together.

Chemical corrosion: Contact with strong acids, strong alkalis or organic solvents may cause corrosion of the glue or the PVC pipe itself, affecting the sealing and firmness of the interface. It is necessary to confirm in advance whether the chemical resistance of the glue matches.