+86 13600513715

+86 13600513715 How Sludge Dewatering Screw Press Machines Work: Efficiency Meets Simplicity

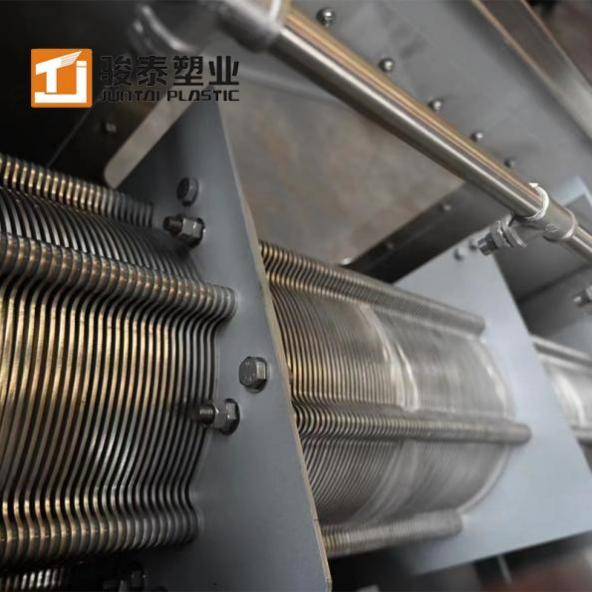

Core Components & Operating Principle

A sludge Dewatering Screw press employs continuous mechanical pressure to separate liquids from solids. Key structural elements include:

-

Screw Shaft: Hardened stainless steel (HRC 58-62) with 5° tapered pitch

-

Screening Drum: Laser-cut 316L slots (0.25-1.5mm adjustable)

-

Back Pressure Plate: Hydraulic-controlled (0-15 bar adjustable)

-

Drive System: 3-phase 5.5kW motor with 87% IE4 efficiency

5-Stage Dewatering Process

-

Sludge Feeding

-

Polymer-conditioned sludge (0.5-1.5% DS) enters via progressive cavity pump

-

Initial gravity drainage removes 15-20% free water

-

-

Compression Zone

-

Screw rotation speed: 2-8 rpm (VFD controlled)

-

Increasing pitch creates axial pressure up to 12 bar

-

-

Shear Filtration

-

Solids travel through narrowing screen gaps

-

90-95% solids capture rate achieved

-

-

Cake Discharge

-

18-35% DS cake expelled through adjustable cone

-

Automatic blade trims cake thickness

-

-

Self-Cleaning

-

Reverse flushing nozzles (10 bar) prevent screen blinding

-

<5 mins/day manual intervention

-

Technical Advantages vs Alternatives

| Parameter | Screw Press | Centrifuge | Belt Press |

|---|---|---|---|

| Energy Use | 0.8-1.2 kWh/ton | 3-5 kWh/ton | 2-3 kWh/ton |

| Noise Level | 65 dB | 85 dB | 75 dB |

| Footprint | 4m² | 8m² | 6m² |

| Polymer Cost | $0.15/ton | $0.30/ton | $0.25/ton |

Typical Applications

-

Municipal WWTPs handling 50-120 m³/day sludge

-

Food processing plants with high-fat sludge (>8% lipid content)

-

PetroChemical Sludge containing 5-15% hydrocarbons

Why Operators Choose Screw Press Tech

✅ 24/7 operation with ≤1% downtime

✅ 40% lower OPEX vs thermal dryers

✅ Handles 3-12% feed solids without pre-thickening