+86 13600513715

+86 13600513715 High aspect ratio MBBR water distribution uneven problem and solution

Overview

Flow Distribution Issues in High Width-to-Length Ratio MBBR

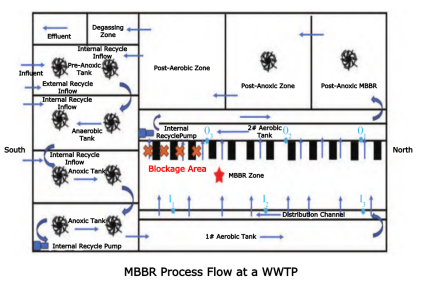

The Moving Bed Biofilm Reactor (MBBR) is widely used in municipal wasteWater Treatment due to its simple structure, small footprint, stable operation, and high treatment efficiency. However, in practical operation, MBBRs with high width-to-length ratios often experience uneven flow distribution between the inlet and outlet, leading to short-circuiting. This phenomenon reduces the effective hydraulic retention time, negatively impacting pollutant removal efficiency, particularly for ammonia nitrogen. This issue is especially prominent in high width-to-length ratio MBBRs and requires operational optimization for resolution.

Causes

Uneven Flow Distribution and Short-Circuiting

The primary causes of flow imbalance in high width-to-length ratio MBBRs are related to their unique tank geometry and hydrodynamic conditions:

- Suboptimal Inlet/Outlet Layout: The proximity of the outlet to the inlet distribution channel allows some wastewater to bypass the reaction zone, resulting in incomplete treatment.

- Non-Uniform Aeration: Traditional aeration systems struggle to achieve even air distribution in high width-to-length ratio tanks, leading to localized over- or under-aeration, which worsens flow maldistribution.

- Impact of Internal Recycle: Improper internal recycle ratios can disrupt flow balance—while higher ratios improve mixing, they may increase energy consumption and exacerbate short-circuiting.

Improvement Measures and Optimization Results

To address flow distribution issues in high width-to-length ratio MBBRs, the following optimization strategies can be implemented:

- Adjusting Internal Recycle Ratio: Modifying the internal recycle ratio (e.g., from 200% to 100% or 300%) can mitigate short-circuiting, but the optimal setting must balance treatment performance and energy efficiency.

- Partial Outlet Blocking: Blocking rear outlet screens extends the flow path, reduces short-circuiting, and maintains nitrification efficiency.

- Aeration System Optimization: Adjusting aeration intensity and distribution improves oxygen transfer efficiency, ensuring more uniform mixing.

- Creating a Drop Structure in the Inlet Channel: Lowering the water level to form a hydraulic drop enhances inlet flow uniformity and minimizes distribution imbalances.

These measures significantly reduce short-circuiting, as confirmed by tracer tests showing improved flow uniformity, extended hydraulic retention time, and more stable effluent quality. This optimization approach provides a practical solution for efficient operation of high width-to-length ratio MBBRs.