+86 13600513715

+86 13600513715 Guide to Maintaining & Replacing Components in Fine Bubble Disc Diffusers

1. Modular Design Simplifies Repairs

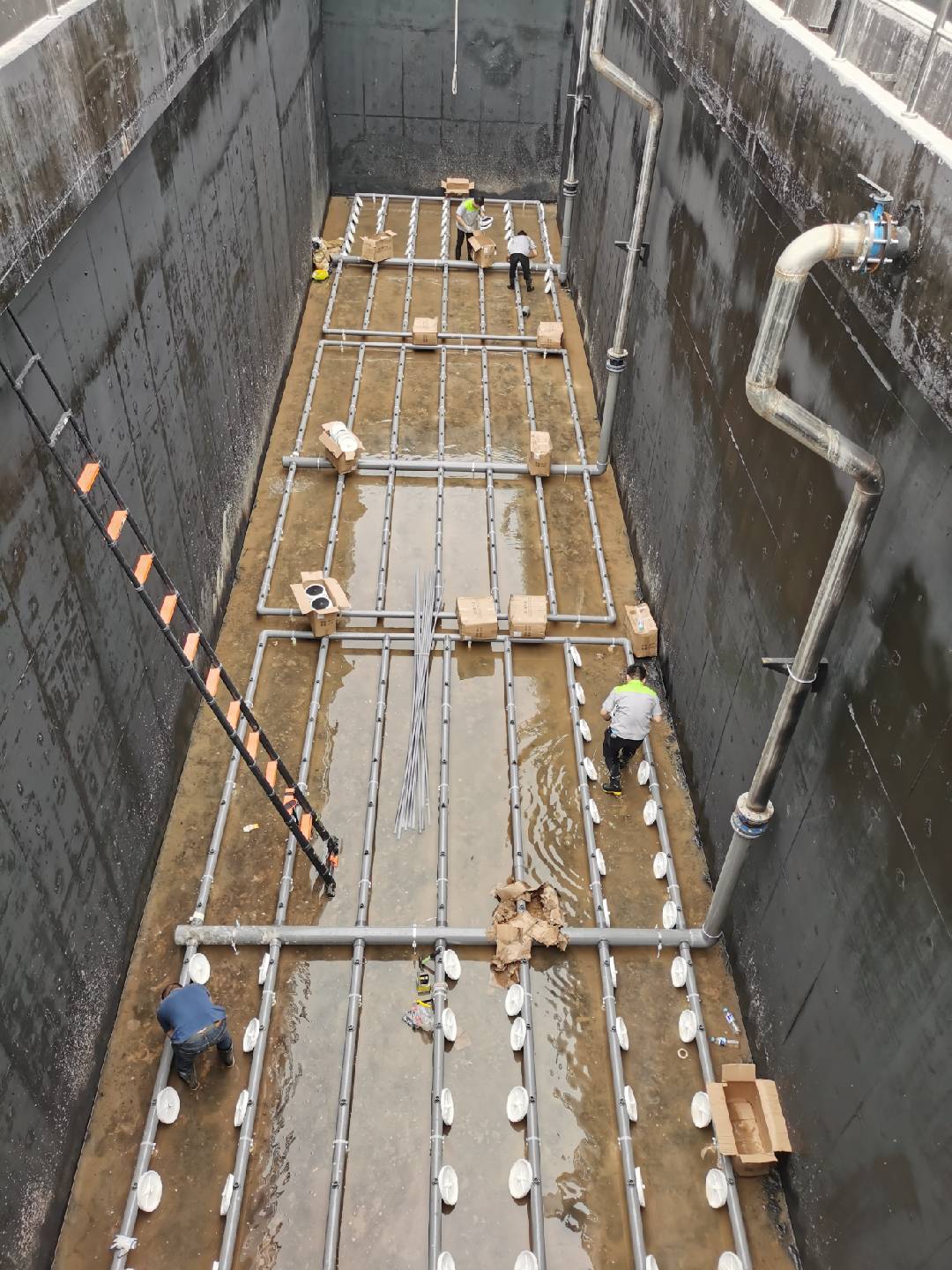

Most modern fine bubble Disc Diffusers feature a modular build, allowing users to replace individual components without dismantling the entire system. For example, EPDM diffuser membranes—known for their chemical resistance—can be swapped out by removing the retaining ring or clamp. This design minimizes downtime in water treatment plants.

-

Key Parts for Replacement: Epdm Diffuser Membranes, silicone gaskets, stainless steel fasteners, and air distribution plates.

-

Tools Required: Non-abrasive cleaning brushes, compatible lubricants, and torque wrenches (for precise tightening).

2. Step-by-Step Membrane Replacement

The membrane is the most frequently replaced component in a bubble disc diffuser due to wear or clogging. Follow these steps:

-

Isolate the System: Shut off airflow to the diffuser in the wastewater treatment tank.

-

Remove the Retaining Mechanism: Unscrew the central bolt or unclip the retaining ring.

-

Extract the Old EPDM Membrane: Gently peel off the worn membrane, taking care not to damage the diffuser base.

-

Clean the Disc Surface: Use a soft brush and mild detergent to remove biofilm or mineral deposits.

-

Install the New Membrane: Align the EPDM air diffuser disc precisely over the orifice pattern.

-

Reassemble and Test: Secure the retaining hardware and perform a leak test at low pressure.

Pro Tip: For coarse bubble disc diffusers, inspect the orifice holes for enlargement, which can affect oxygen transfer efficiency.

3. Addressing Common Challenges

-

Fouling in Wastewater Air Diffusers: Biofilm and solids buildup in sewage treatment plants can block pores. Use citric acid soaks for EPDM membranes or replace them if cleaning fails.

-

Corrosion in Brackish Environments: Opt for 316L stainless steel hardware in disk aerators exposed to saltwater.

-

Compatibility Issues: Verify that replacement parts (e.g., FlexAir 9 disc air diffuser membranes) match the original specs.

4. Cost Considerations: Disc Diffuser Price vs. Longevity

While the upfront disc diffuser price may vary by material and size (e.g., 12 disc diffuser units for large tanks), investing in durable components like EPDM air diffuser discs reduces long-term expenses. Budget for:

-

EPDM Membranes: 15–50 per unit, depending on diameter.

-

Gasket Kits: 5–20 per set.

-

Labor Costs: Factor in confined-space entry permits if servicing deep tanks.

5. Installation Best Practices for Disc-Type Air Diffusers

Proper disc diffuser installation ensures optimal aeration and extends service life:

-

Spacing: Position pond air discs at least 12–18 inches apart to prevent airflow interference.

-

Anchoring: Use weighted bases or suction cups for submerged disk aerators in moving water.

-

Airflow Calibration: Adjust blower output to 2–5 psi for fine bubble diffusers in wastewater treatment.