+86 13600513715

+86 13600513715 Factors Affecting Anaerobic Biological Treatment -- Part 1

Introduction

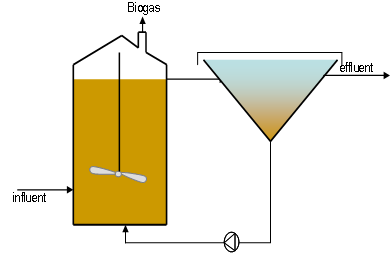

Anaerobic biological treatment is a widely used process for degrading organic pollutants in the absence of oxygen, producing methane (CH₄) and carbon dioxide (CO₂) as byproducts. This method is highly efficient for high-strength wastewater and sludge stabilization, offering advantages such as low energy consumption and minimal sludge production. However, its performance depends on several critical factors:

(1) temperature, (2) pH, (3) organic loading rate (OLR), (4) nutrient balance, (5) oxidation-reduction potential (ORP), (6) alkalinity, (7) toxic substances, and (8) hydraulic retention time (HRT).

Understanding these factors is essential for optimizing process stability and treatment efficiency.

Hydraulic Retention Time (HRT)

It is essential to ensure both the hydraulic retention time (HRT) and the solids retention time (SRT) in anaerobic biological treatment. HRT is related to the nature of the organic pollutants in the wastewater to be treated—simple low-molecular-weight organic compounds require a shorter HRT, while complex macromolecular organic compounds demand a longer HRT. The SRT in anaerobic biological treatment processes is generally prolonged to ensure sufficient biomass in the reactor.

Excessive hydraulic loading leading to an overly short HRT may result in the washout of microorganisms from the reactor. Therefore, attempting to treat low-concentration wastewater using suspended-growth processes like UASB under short HRT conditions is often impractical. To economically apply anaerobic technology for low-concentration Wastewater Treatment, it is necessary to increase the SRT-to-HRT ratio, i.e., by enhancing the biomass within the reactor.

The influence of HRT on anaerobic processes is primarily reflected in the upflow velocity. On one hand, a higher flow velocity can improve turbulence in the influent zone of the wastewater system, thereby enhancing contact between the biological sludge and organic matter in the influent and increasing the organic removal efficiency. When using conventional UASB for wastewater treatment, an upflow velocity of at least 0.5 m/h is generally required to promote granule sludge formation. On the other hand, to maintain sufficient sludge in the system, the upflow velocity must not exceed a certain limit; otherwise, the height of the anaerobic reactor would become impractically high. Particularly in anaerobic treatment of low-concentration wastewater, HRT is a more critical process control parameter than organic loading.

Anaerobic Biological Wastewater Treatment

Organic Loading Rate

- The organic loading rate (OLR) of an anaerobic bioreactor typically refers to the volumetric loading rate, which directly affects treatment efficiency and biogas production. Within a certain range, as the OLR increases, biogas production rises. However, an increase in OLR inevitably shortens the retention time, reducing the decomposition rate of influent organic matter and consequently decreasing biogas production per unit mass of organic matter.

- The stable operation of an anaerobic treatment system depends on the balance between acidogenesis and methanogenesis rates. If the OLR is too high, the acid production rate may exceed the acid consumption rate by methanogens, leading to volatile fatty acid (VFA) accumulation and a rapid pH drop, which inhibits methanogenesis. In severe cases, methane production may cease, causing the entire system to collapse, making recovery and adjustment extremely difficult.

- If the increase in OLR is due to higher influent flow rate, excessive hydraulic loading may cause the sludge washout rate to exceed its growth rate, further reducing the system’s treatment efficiency.

- If the influent OLR is too low, although the biogas yield and organic removal efficiency may improve, the equipment utilization rate decreases, leading to higher investment and operating costs.

Nutrients

Compared to aerobic processes, anaerobic processes significantly reduce microbial biomass synthesis, thereby proportionally decreasing the demand for nutrients other than nitrogen. In addition to nitrogen (N) and phosphorus (P), certain sulfur-containing compounds (e.g., sulfates) and some trace metals play a crucial role in activating methanogens. Although methanogens have specific requirements for sulfur and phosphorus, very low concentrations of these elements in the reactor are usually sufficient. However, nitrogen concentrations must generally be maintained within 40–70 mg/L to sustain methanogenic activity.

All microorganisms require trace metals, but their levels in anaerobic biological treatment can significantly impact operational performance. Iron (Fe), cobalt (Co), nickel (Ni), and zinc (Zn) are the most commonly reported trace metals with activating effects, while some studies suggest that tungsten (W), manganese (Mn), molybdenum (Mo), selenium (Se), and boron (B) may also stimulate methanogen metabolism.

Methane is produced by different species of methanogens, each with unique environmental and trace metal requirements. Operational experience shows that a deficiency in even a single trace metal can severely impair the entire biological treatment process. While trace metals alone cannot resolve all operational challenges in anaerobic treatment, their presence is a fundamental prerequisite. Many anaerobic industrial wastewater treatment systems fail to achieve expected performance due to deficiencies in one or more trace metals. Therefore, supplementing trace metals should be considered a necessary operational adjustment.

Anaerobic microorganisms require a specific ratio of carbon (C), nitrogen (N), phosphorus (P), and other trace elements for growth and reproduction. However, since anaerobic microbes utilize carbon less efficiently than aerobic microbes, the recommended C:N:P ratio in anaerobic systems is typically COD<sub>Cr</sub>:N:P = (200–300):5:1. Additionally, depending on specific conditions, essential trace elements such as sulfides, iron, nickel, zinc, cobalt, and molybdenum may need to be supplemented.

Providing nitrogen sources in anaerobic treatment not only supports microbial biomass synthesis but also enhances the reactor’s buffering capacity. Insufficient nitrogen (i.e., a high C/N ratio) can lead to slow anaerobic microbe proliferation and reduced buffering capacity, causing pH to drop. Conversely, excessive nitrogen (low C/N ratio) results in nitrogen accumulation, raising pH. If pH exceeds 8, methanogen activity is inhibited, reducing digestion efficiency.

Oxidation-Reduction Potential (ORP)

An anaerobic environment is one of the fundamental conditions for the growth and reproduction of strictly anaerobic methanogens. Unlike aerobic bacteria, methanogens lack catalase, making them highly sensitive to oxygen and oxidizing agents. The dissolved oxygen concentration in water can be indirectly represented by the oxidation-reduction potential (ORP).

In anaerobic digestion, the non-methanogenic phase can proceed under facultative conditions with an ORP range of +100 mV to -100 mV. However, the critical ORP for the methanogenic phase is -200 mV. For mesophilic or ambient-temperature digestion, the ORP must be maintained between -300 mV and -350 mV, while for thermophilic digestion, it should be controlled within -560 mV to -600 mV.

While dissolved oxygen content in the mixed liquor is a major factor affecting ORP in anaerobic reactors, it is not the only one. Other factors, such as volatile fatty acid (VFA) concentration, pH fluctuations, and ammonium ion concentration, can also influence ORP changes. For instance, a lower pH corresponds to a higher ORP, whereas a higher pH results in a lower ORP.