+86 13600513715

+86 13600513715 Common Types of Oxidation Ditches

Common Types of Oxidation Ditches

- Carrousel Oxidation Ditch: Uses vertical low-speed surface aerators for oxygen supply and to propel water flow.

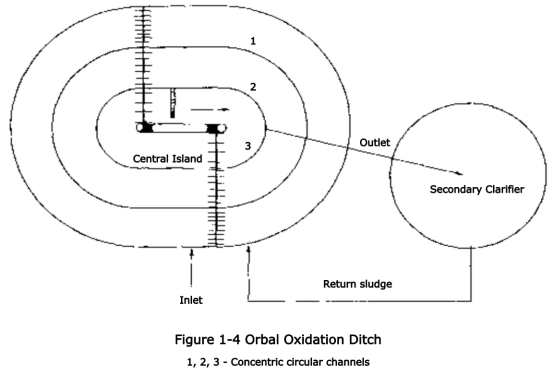

- Orbal Oxidation Ditch: Consists of multiple concentric channels, with wastewater flowing sequentially from the outer to the inner channel. Each channel has different organic matter and dissolved oxygen concentrations.

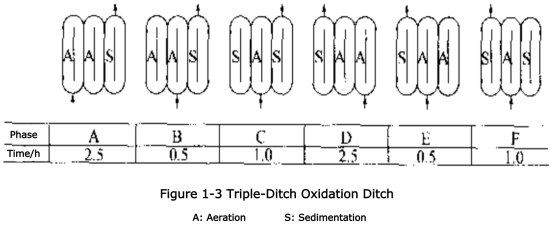

- Alternating Oxidation Ditch: Includes double-ditch (D-type) and triple-ditch (T-type) systems, where each ditch alternates between aerobic and sedimentation states, improving equipment utilization. The equipment utilization rates for D-type and T-type oxidation ditches are 50% and 58.3%, respectively.

- Integrated Oxidation Ditch: Combines the oxidation ditch and secondary clarifier into a single unit.

- Other Types of Oxidation Ditches: Include U-shaped oxidation ditches, jet aeration systems, and counter-current oxidation ditches with microporous aeration.

Integrated Oxidation Ditch

The integrated oxidation ditch, also known as a combined oxidation ditch, integrates functions such as aeration, sedimentation, sludge-water separation, and sludge return into a single unit, eliminating the need for a separate secondary clarifier. The earliest oxidation ditches were also integrated, operating intermittently to complete both aeration and sedimentation in one ditch. However, modern integrated oxidation ditches refer to those equipped with specialized solid-liquid separation devices.

Common solid-liquid separation configurations include built-in and external types.

In addition to the general characteristics of oxidation ditches, integrated oxidation ditches have the following four features:

- Shorter process flow, fewer structures and equipment, eliminating the need for primary sedimentation tanks, regulating tanks, and separate secondary clarifiers.

- Better solid-liquid separationthan conventional clarifiers, ensuring stable operation under varying flow or load conditions.

- Automatic sludge returnfrom the sedimentation zone to the oxidation ditch (either by gravity or partial mechanical force), simplifying management and eliminating the need for sludge return pump stations, associated equipment, and piping—thus reducing costs and footprint.

- Lower overall failurerate and reduced operational workload.

Built-in Integrated Oxidation Ditch

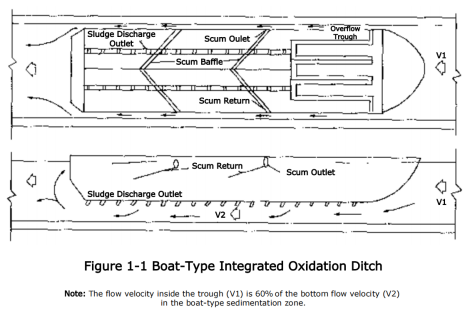

The built-in solid-liquid separation device is installed across the oxidation ditch’s cross-section, utilizing principles of vertical and inclined plate sedimentation. As mixed liquor flows beneath the separator, it rises upward, allowing sludge (with slower rising velocity) to separate from the supernatant. The pressure difference between the relatively static water in the separator and the flowing water in the ditch creates a suction effect, automatically returning settled sludge to the reactor for remixing. This design is highly influenced by hydraulic conditions in the ditch. Common built-in separators include boat-type (Fig. 1-1) and BMTS-type.

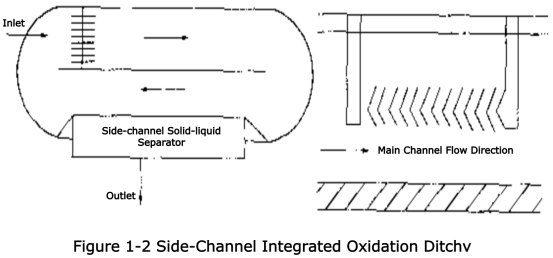

Side-channel Integrated Oxidation Ditch

The external solid-liquid separation device has minimal impact on the ditch’s cross-section and normal flow conditions, offering better hydraulic performance. A typical example is the side-channel separator (Fig. 1-2).

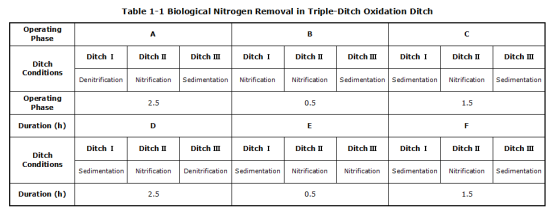

Alternating Oxidation Ditch

Common alternating systems include double-ditch (D-type) and triple-ditch (T-type) oxidation ditches, which use brush aerators. Due to the higher idle rate of D-type systems (over 50%), T-type ditches are more widely applied. The T-type ditch functions as an A/O activated sludge system with biological nitrogen removal capabilities. The traditional BOD₅ removal operation mode is shown in Fig. 1-3, while the nitrogen removal operation mode is detailed in Table 1-1.

Orbal Oxidation Ditch

The Orbal oxidation ditch is a multi-stage system equipped with Disc Aerators for oxygenation and mixing. It operates at a water depth of 2–3.6 m and a bottom flow velocity of 0.3–0.9 m/s. Its unique design features concentric circular channels(Fig. 1-4). Wastewater enters the outermost channel, circulates, and then flows sequentially into inner channels—functioning like a series of completely mixed reactors—before being discharged from the central channel.

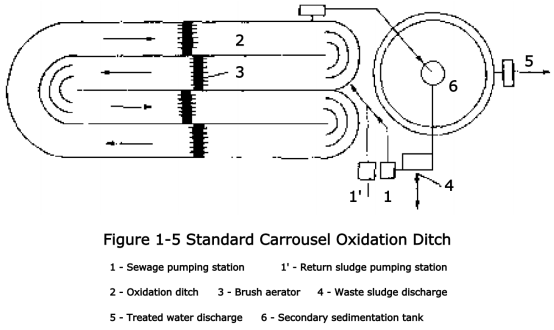

Carrousel Oxidation Ditch

The Carrousel oxidation ditch employs vertical low-speed surface aerators for oxygenation and flow propulsion, addressing the technical limitations of brush-aerated ditches. It allows for greater channel depth and higher efficiency. A standard Carrousel configuration is shown in Fig. 1-5.