+86 13600513715

+86 13600513715 Coarse Bubble Diffusers: High-Solids Aeration & Maintenance Guide | JUNTAI

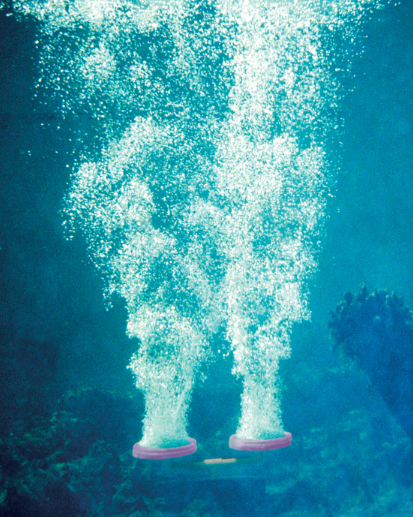

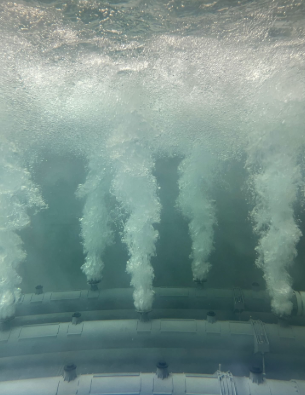

Optimizing Coarse Bubble Diffusers for Robust Wastewater Aeration

Introduction: Strategic Applications of Coarse Bubble Technology

Coarse bubble diffusers (bubble diameter >5mm) deliver unmatched reliability in high-solids and challenging wastewater environments. While offering 15-25% lower oxygen transfer efficiency (OTE) than fine bubble systems, they excel in applications where fouling resistance, mixing intensity, and operational simplicity are critical. Industrial plants treating fibrous, high-TSS (>1000 mg/L), or viscoUs Wastewater leverage coarse bubble aerators to minimize downtime and maintenance costs. This guide details engineering principles for maximizing performance in abrasive, variable-load conditions.

1. Material Engineering for Harsh Environments

1.1 Polymer Selection for Durability

-

Reinforced EPDM (6-8mm thickness):

-

Optimal for: Municipal sludge digestion, temperatures ≤60°C

-

Tear Strength: >40 kN/m (ASTM D624)

-

-

Abrasion-Resistant Polyurethane (PU):

-

Industrial Use: Pulp/paper mills, mining effluents with >5% solids

-

Impact Resistance: 3× higher than standard EPDM

-

-

Perfluoroelastomer (FFKM) Liners:

-

Chemical Resistance: Withstands pH 1-12, solvents, and hydrocarbons

-

1.2 Structural Reinforcement

-

Stainless Steel Backing Plates (SS316L): Prevent deformation at >2 bar pressure

-

Boltless Clamping System: Eliminates corrosion points in saline environments

-

Anti-Siphon Valves: Integrated into diffuser base to prevent backflow

2. Hydrodynamic Design & System Integration

2.1 Bubble Dynamics & Mixing Efficiency

-

Bubble Size Control: 5-8mm diameter balances shear force and oxygen dissolution

-

Vertical Velocity Gradient: >0.3 m/sec prevents solids settling

-

Tank Aspect Ratio Optimization:

-

Depth ≥4m: Staggered diffuser rows

-

Depth <4m: Angled deflectors (30°-45°)

-

2.2 Airflow Distribution Engineering

Table: Coarse Bubble Diffuser Configurations by Application

| Wastewater Type | Diffuser Density (units/m²) | Airflow Rate (Nm³/h/unit) | Header Pressure (bar) |

|---|---|---|---|

| Municipal Activated Sludge | 0.5-0.7 | 10-15 | 0.8-1.2 |

| Industrial (High TSS) | 0.8-1.2 | 15-25 | 1.5-2.0 |

| Anaerobic Digestion | 1.5-2.0 | 8-12 | 1.0-1.5 |

| Equalization Tanks | 0.3-0.5 | 20-30 | 0.6-1.0 |

3. Operational Protocols for Peak Performance

3.1 Fouling Mitigation Strategies

-

Pulsed Aeration Cycles:

-

5 minutes at 120% design flow every 4 hours dislodges surface scum

-

-

Mechanical Cleaning Systems:

-

Retractable diffusers with integrated spray nozzles (monthly cleaning)

-

-

Chemical Resistance Testing:

-

Quarterly exposure tests to site-specific contaminants

-

3.2 Energy Optimization Techniques

-

Turndown Ratio Management:

-

Maintain ≥40% turndown capability for load variations

-

PD blowers preferred over centrifugals for pressure stability

-

-

DO Control Philosophy:

-

Accept wider DO bands (1.0-3.0 mg/L) to reduce valve adjustments

-

Zone-based aeration for large basins

-

4. Maintenance & Failure Diagnostics

4.1 Performance Degradation Indicators

| Symptom | Root Cause | Corrective Action |

|---|---|---|

| Reduced mixing vortices | Orifice blockage | High-pressure air scour (4 bar) |

| Uneven tank mixing | Header pressure imbalance | Rebalance control valves |

| Metal fatigue cracks | Cyclic stress corrosion | Upgrade to duplex stainless steel |

| Airflow surge | Membrane delamination | Replace membrane & clamp assembly |

4.2 Predictive Maintenance Schedule

-

Monthly:

-

Visual inspection for biofilm accumulation

-

Airflow uniformity test (±15% tolerance)

-

-

Quarterly:

-

Polymer hardness testing (Shore A scale)

-

Bolt torque verification (50-60 Nm)

-

-

Annual:

-

Full tensile strength evaluation (ASTM D412)

-

5. Comparative Advantage vs. Fine Bubble Systems

5.1 Operational Trade-off Analysis

| Parameter | Coarse Bubble | Fine Bubble |

|---|---|---|

| OTE (%) | 4-6 | 6-9 |

| Fouling Resistance | Excellent | Moderate-Poor |

| Mixing Energy (W/m³) | 25-40 | 15-25 |

| Maintenance Interval | 24-36 months | 6-12 months |

| Ideal TSS Range | 500-5000 mg/L | <300 mg/L |

5.2 Retrofit Economics

-

Payback Calculation:

-

60% lower membrane replacement costs

-

30% reduced energy for mixing-dominated processes

-

-

Blower Compatibility:

-

Works with existing coarse bubble blowers (no VFD required)

-

Conclusion: Engineering for Reliability Over Efficiency

Coarse bubble diffusers deliver maximum uptime in wastewater applications where solids loading, variable composition, or abrasive conditions dictate system design. By prioritizing robust materials (reinforced EPDM/PU), simplified maintenance protocols, and mixing-focused engineering, plants achieve <1% unscheduled downtime while maintaining compliance.