+86 13600513715

+86 13600513715 Biological Filters: Types, Loadings & Operation

Biological Filters

Types and Characteristics of Biological Filters

Biological filters are an artificial biological treatment method developed based on intermittent sand filters and contact filters. In a biological filter, wastewater is evenly distributed across the filter surface by a distributor, while the filter is packed with media. The wastewater flows downward through the voids in the media to the bottom of the tank. As the wastewater passes through the filter, suspended solids are retained by the media, while colloidal and dissolved substances are adsorbed onto its surface. The organic matter in the wastewater promotes rapid microbial growth, and these microorganisms further adsorb suspended, colloidal, or dissolved substances, gradually forming a biofilm. Once the biofilm matures, the microorganisms inhabiting it metabolize organic pollutants in the wastewater as nutrients, facilitating adsorption and oxidation. Thus, the wastewater is purified as it passes through the biological filter.

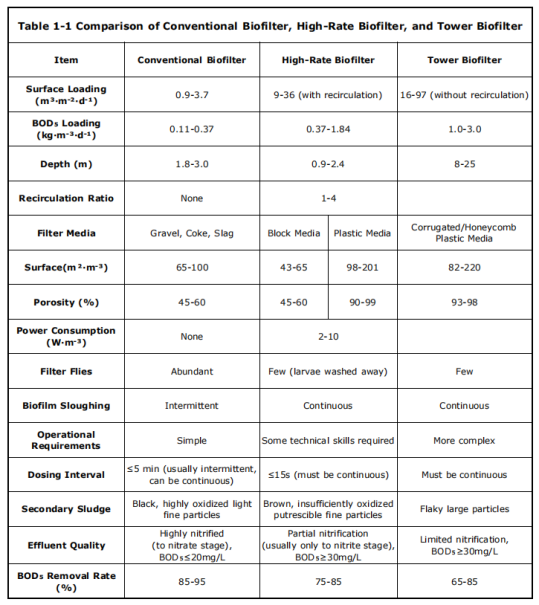

Common types of biological filters include conventional biofilters, high-rate biofilters, and tower biofilters. Table 1-1 lists the fundamental parameters of these three types.

Loading Rates of Biological Filters

The loading rates of biological filters are categorized into organic loading and hydraulic loading.

- Hydraulic Loading: Refers to the daily wastewater volume that can be treated per unit volume of media or per unit surface area of the filter while ensuring effluent quality. The former is called hydraulic volumetric loading, with units of m³/(m³·d), while the latter is called hydraulic surface loading, with units of m³/(m²·d)or m/d (also referred to as filtration rate). If a recirculation system is used, the calculation of hydraulic loading should include the recirculated flow.

- Organic Loading: Refers to the amount of organic matter entering or being removed per unit volume of filter media per day, also known as organic volumetric loading, with units of kg BOD₅/(m³·d). The latter represents the oxidation capacity of the biofilter, while the former must specify the removal efficiency to truly reflect the filter’s performance. Essentially, the organic loading rate reflects the treatment capacity of the biological filter.

For conventional biofilters treating domestic wastewater or municipal wastewater primarily composed of domestic sewage, the typical hydraulic loading ranges from 1–3 m³/(m²·d), and the BOD volumetric loading is generally 0.15–0.30 kg BOD₅/(m³·d).

Characteristics of Biological Filters

The greatest advantage of biological filters is their simple construction, ease of operation, and ability to withstand shock loads of toxic or organic wastewater. This is because the hydraulic retention time (HRT) in biofilters is relatively short—even if surface microorganisms are killed and sloughed off, a new layer of unaffected biomass is exposed. However, if the shock load of toxic wastewater or organic matter persists for an extended period, or if toxic substances accumulate in the biofilm, the treatment efficiency of the biofilter will be severely affected.

Since microorganisms grow attached to the fixed surface of the filter media, the biomass in the reactor cannot adjust dynamically to environmental changes. Therefore, there is no effective method to control effluent quality. Consequently:

- If influent concentration or flow rate increases (i.e., organic or hydraulic loading rises), effluent quality deteriorates.

- If influent temperature or ambient temperature decreases, the substrate removal rate also declines.

This fixed-film nature limits operational flexibility but ensures stability under moderate variations.