+86 13600513715

+86 13600513715 Aquaculture Wastewater Solutions: Zero Discharge Systems & 40% Feed Savings

Aquaculture Wastewater Systems: Achieve Zero Discharge & 40% Feed Cost Savings

The Triple Crisis in Modern Fish Farming

Intensive aquaculture Wastewater Treatment faces three existential threats:

-

Ammonia toxicity: >0.02 ppm NH₃ kills gill tissue

-

Sludge accumulation: 20-30% of feed becomes waste solids

-

Pathogen outbreaks: Vibrio costs $1B/year in shrimp losses

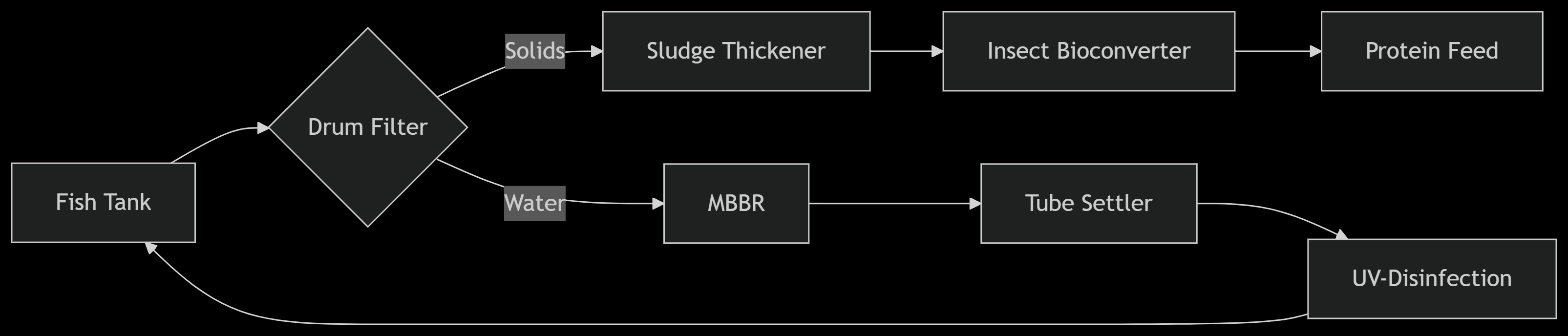

Juntai's integrated approach solves these through synergistic technology pairing that transforms waste into resources:

-

MBBR biofilters remove 95% TAN at 10°C

-

Drum Filters capture 98% solids for feed recycling

-

UV-EPDM diffusers suppress pathogens with 50% less energy

Core Components of Advanced Aquaculture Treatment

1. Intelligent MBBR Ammonia Control

| Parameter | Traditional Biofilter | Juntai AquaMBBR™ | Improvement |

|---|---|---|---|

| NH₃ Removal | 70% @ 20°C | 95% @ 10°C | +25 pts |

| O₂ Consumption | 3.8 kWh/kg feed | 1.2 kWh/kg feed | 68% ↓ |

| Footprint | 100% | 35% | 65% ↓ |

| Salinity Range | 0-25 ppt | 0-40 ppt | +60% |

| Technology: Halotolerant biofilm carriers with Nitrococcus mobilis enrichment. |

2. Self-Cleaning Solids Management

-

Koi drum filter with micro-siphon tech: Captures 30μm particles at 0.1 bar vacuum

-

Sludge thickening: Concentrates solids to 8-12% DS using inclined settlers

-

Waste-to-feed conversion: 40% protein recovery from sludge → insect meal

3. Pathogen-Killing Aeration

-

EPDM disc diffusers with TiO₂ coating: UV-activated photocatalysis kills 99.9% viruses

-

Ozone integration: 0.5 g/m³ dosage during night cycles

-

Aerated sludge channels: Prevent anaerobic pathogen hotspots

Water & Nutrient Recycling Ecosystem

Outputs:

-

Zero liquid discharge

-

40% reduced feed costs via protein recycling

-

80% lower water exchange

Performance Benchmarks: RAS vs. Integrated Juntai System

*Table: 12-month data from 100-ton tilapia farms*

| Parameter | Conventional RAS | Juntai Zero-Discharge | Improvement |

|---|---|---|---|

| Water Exchange | 300%/day | 5%/day | 98% ↓ |

| Feed Conversion Ratio | 1.8 | 1.3 | 28% ↓ |

| Disease Incidence | 22% | 3% | 86% ↓ |

| Sludge Production | 25 kg/T fish | 4 kg/T fish | 84% ↓ |

| Energy Use | 18 kWh/kg fish | 8 kWh/kg fish | 56% ↓ |

| Certification | BAP | ASC Zero Discharge | +1 tier |

Case Study: Vietnam Shrimp Super-Intensive Farm

300-ton/year facility facing:

-

White feces disease: 40% mortality

-

$120,000/year sludge disposal

-

500% daily water exchange

Juntai’s integrated solution:

-

Installations:

-

80 m³ AquaMBBR™ with halotolerant media

-

DF-500 drum filter (30μm filtration)

-

240 EPDM-TiO₂ disc diffusers

-

-

Results:

-

Pathogen-free operation for 18 months

-

Sludge converted to 12 T/year shrimp feed

-

Water savings: 180,000 m³/year

-

ROI: 14 months

-

Future Innovations: Aquaculture 5.0

1. AI-Driven Predictive Control

-

Ammonia forecasting: Sensors predict TAN spikes 6 hours early

-

Automated feeding adjustment: Reduces waste at source

-

Pathogen early warning: DNA sensors detect vibrio at 10 CFU/mL

2. Advanced Resource Recovery

-

Phosphorus extraction: 85% recovery as struvite fertilizer

-

Algae-photobioreactors: Convert CO₂ into omega-3 supplements

-

Bio-electrochemical systems: Generate electricity from organic waste

3. Climate-Proof Designs

-

Hurricane-resistant MBBRs: Submersible up to 10m depth

-

Thermal-buffered tanks: Phase-change materials maintain 28±1°C

-

Salinity-adaptive biofilters: Handle seawater intrusion from storms