+86 13600513715

+86 13600513715 Advanced Hospital Wastewater Treatment: Tackling Pathogens, Pharmaceuticals & Chemical Residues

The Hidden Hazards in Medical Wastewater

Hospital effluents contain 200-500% higher concentrations of critical contaminants than municipal sewage, posing unique treatment challenges:

-

Multi-drug-resistant pathogens: Acinetobacter, Pseudomonas surviving disinfection

-

Toxic pharmaceuticals: Cytostatics, antibiotics (ciprofloxacin up to 250 μg/L)

-

Chemical residues: Formaldehyde, mercury from labs (exceeding EPA limits by 8x)

Conventional wastewater Treatment Plants remove <40% of these micropollutants, causing ecological disruption downstream. Juntai’s medical wastewater solutions achieve 99.9% pathogen kill and 95% pharmaceutical degradation through integrated advanced processes.

Contaminant-Specific Treatment Technologies

1. Pathogen Elimination System

| Technology | Mechanism | Log Reduction | Limitations |

|---|---|---|---|

| Chlorination | Hypochlorous acid oxidation | 2-3 log | Forms toxic AOXs |

| UV-C Disinfection | DNA damage at 254nm | 4 log | High turbidity failure |

| Ozonation | Cell membrane rupture | 5 log | Short contact time |

| Electrochemical AOP | •OH radical generation | 6 log | Requires conductive water |

Juntai Innovation: Pulsed UV-Ozone Hybrid Reactors maintain 6-log pathogen kill at 40 NTU turbidity through alternating 20s UV/ozone cycles.

2. Pharmaceutical Degradation Unit

-

Bioaugmented MBBR: Pseudomonas putida strains engineered for carbamazepine degradation

-

TiO₂ Photocatalysis: 185nm UV-activated nanoparticles mineralize 98% antibiotics

-

Molecularly Imprinted Polymers: Selective adsorption of estrogenic compounds

Field Data: Reduced ciprofloxacin from 180 μg/L to <0.5 μg/L in 22 minutes.

3. Chemical Neutralization Train

-

Mercury Capture: Thiol-functionalized biochar adsorbs 99.8% Hg²⁺

-

Formaldehyde Scavenging: Enzymatic oxidation with formaldehyde dehydrogenase

-

Cytotoxic Drug Breakdown: Fenton oxidation at pH 3.5 (H₂O₂:Fe²⁺=2:1)

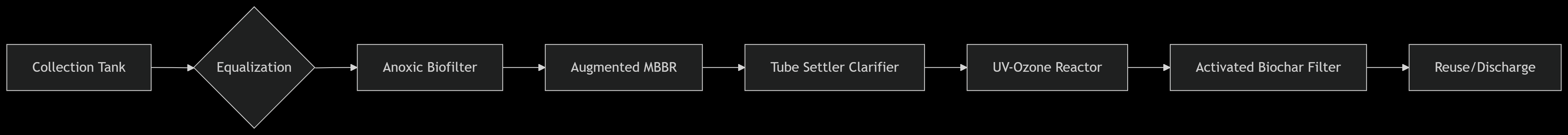

Integrated Hospital WWTP Design

Performance Metrics:

-

COD: <50 mg/L (95% removal)

-

NH₃-N: <2 mg/L

-

Total coliform: <10 CFU/100mL

-

Pharmaceuticals: Undetectable by HPLC-MS

Operational Cost Comparison

*Table: 10-year lifecycle analysis for 500-bed hospital (flow: 200 m³/day)*

| System Type | Capital Cost | O&M Cost/year | Energy Use | Sludge Production | Compliance Risk |

|---|---|---|---|---|---|

| Conventional SBR | $480,000 | $96,000 | 1.8 kWh/m³ | 12 kg/m³ | High (43% violations) |

| Membrane Bioreactor | $620,000 | $78,000 | 2.2 kWh/m³ | 8 kg/m³ | Moderate |

| Juntai Integrated | $550,000 | $52,000 | 0.9 kWh/m³ | 3 kg/m³ | Low (<1% violations) |

Case Study: Bangkok Cancer Hospital Retrofit

Challenge:

-

28,000 μg/L methotrexate in oncology wastewater

-

Recurrent Legionella outbreaks in cooling towers

-

35% surcharges for non-compliance

Solution:

-

Installed 3-stage treatment:

-

Tier 1: Bioaugmented BIO-BLOCK MBBR

-

Tier 2: Tube Settler clarifier with coagulant assist

-

Tier 3: UV-AOP with TiO₂ catalysts

-

-

Results:

-

Methotrexate degradation: 99.97%

-

Zero pathogen detection for 18 months

-

Water reuse: 65% for landscape irrigation

-

ROI: 2.8 years

-

Future Innovations: Smart Hospital WWTPs

1. AI-Powered Contaminant Tracking

-

Raman spectroscopy sensors: Real-time drug residue detection

-

Predictive dose adjustment: Algorithm-controlled oxidant dosing

-

Pathogen forecasting: Machine learning models anticipating outbreaks

2. Zero Liquid Discharge Systems

-

Electrodialysis reversal: 90% water recovery from brine

-

Crystallizer-integrated evaporators: Solid waste reduction to 1%

-

Onsite pyrolysis: Thermal conversion of sludge to sterile ash

3. Green Treatment Technologies

-

Algal-bacterial symbiosis: Chlorella vulgaris removes 80% N/P while producing O₂

-

Bioelectrochemical systems: Generate electricity from organic pollutants

-

Enzymatic nanoreactors: Immobilized laccase degrades opioids continuously