+86 13600513715

+86 13600513715

01

China MBR Membrane Bioreactor for Wastewater Treatment

Product Parameters

|

MBR Membrane design flux reference table |

|||

| Type of sewage | Design run membrane flux l/m2. h | The maximum operating membrane flux L/m2 is allowed when the water fluctuates greatly. h | Remarks |

| Secondary settling tank effluent | 23-25 | 30 | Standard effluent, pure membrane filtration |

| Domestic / Municipal Waste Water | 19-22 | 25 | Good biodegradability |

| Aquaculture wastewater | 17-18 | 22 | Good biochemistry |

| Industrial sewage | 15-16 | 17-18 | General biodegradability |

| Landfill Leachate | 10-11 | 13-14 | General biodegradability |

| Directions: L/m2. h refers to the water output of a flat rice film for an hour in units such as:19L/m2. h Refers to 19 litres of effluent from a flat rice membrane for an hour | |||

| For large-scale mbr film projects, especially for complex industrial wastewater, it is best to explore and verify the process and design parameters by trial or pilot tests | |||

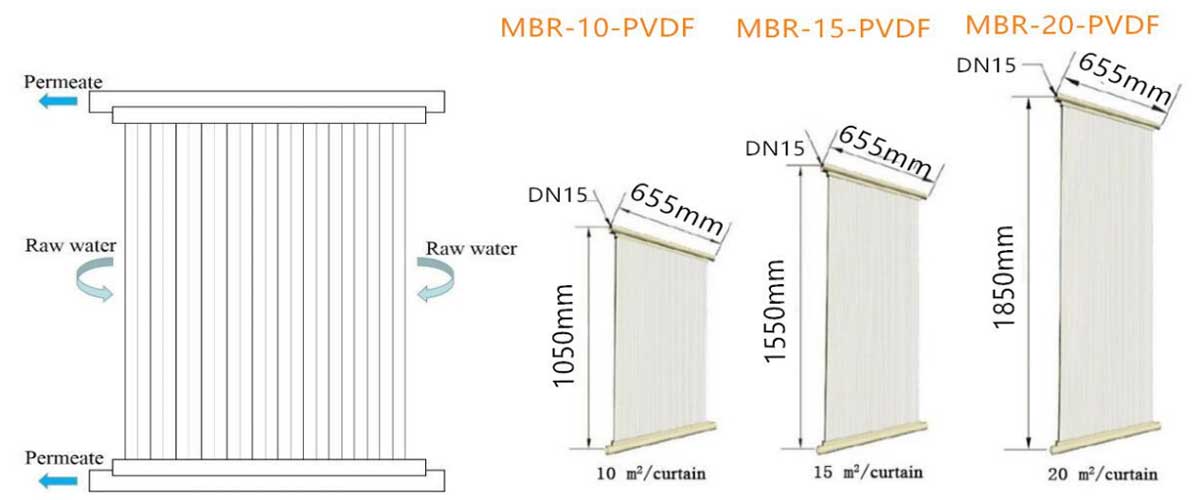

| MBR-10-PVDF | MBR-15-PVDF | MBR-20 PVDF | |

| Component Length A | 1050mm | 1550mm | 1850mm |

| Component Width B | 655mm | 655mm | 655mm |

| Outlet diameter | DN15 | DN15 | DN15 |

| Air intake diameter | DN15 | DN15 | DN15 |

| Component membrane area | 10 | 15 | 20 |

| Shell material | ABS/UPVC | ABS/UPVC | ABS/UPVC |

| Hollow fiber membrane material | PVDF(Enhanced) | PVDF(Enhanced) | PVDF(Enhanced) |

| Inner diameter of hollow fiber membrane | 0.05um | 0.05um | 0.05um |

| Outer diameter of hollow fiber membrane | 1.0mm | 1.0mm | 1.0mm |

| Outer diameter of hollow fiber membrane | 2.4mm | 2.4mm | 2.4mm |

| life | 3-5years | 3-5years | 3-5years |

| Temperature tolerance | 1-40℃ | 1-40℃ | 1-40℃ |

| PH tolerance | 2-13 | 2-13 | 2-13 |

| Operator | Negative pressure adsorption | Negative pressure adsorption | Negative pressure adsorption |

| Water flow | 2.5-3.0t/d | 3.5-5.0t/d | 5.0-7.0t/d |

| Maximum transmembrane pressure difference | -0.08MPa | -0.08MPa | -0.08MPa |

| Effluent cycle | out 8min,keep 2min | out 8min,keep 2min | out 8min,keep 2min |

| Maximum backwash pressure | 0.1MPa | 0.1MPa | 0.1MPa |

| Chemical sterilization agents | chloros | chloros | chloros |

| Chemical cleaning cycle | 6-12 months | 6-12 months | 6-12 months |

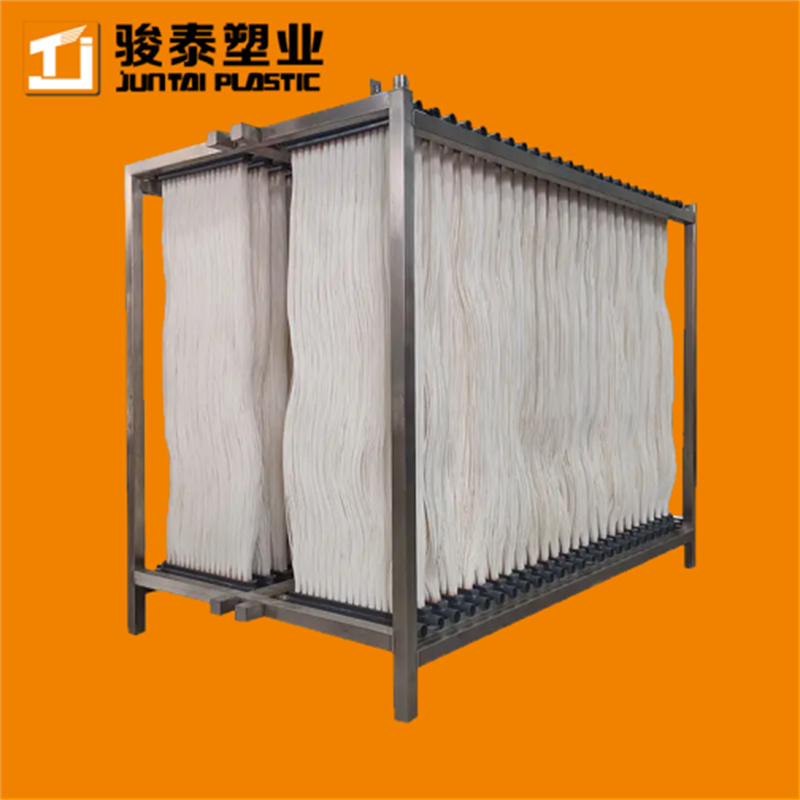

| Specification of MBR Casettes | ||||

| watertreatm ent capacity (m3/d) | MBR part No. | Out diamensions(L xW x H mm) | Number of MBR (pieces) | MBR Square Area (m2) |

| 5-7 | MBR-10X2 | 700*780*800 | 2 | 20 |

| 10 | MBR-10X3 | 700*380*1400 | 3 | 30 |

| 20 | MBR-10X6 | 700*680*1400 | 6 | 60 |

| 30 | MBR-10X9 | 980*700*1400 | 9 | 90 |

| 40 | MBR-10X12 | 1180*800*1400 | 12 | 120 |

| 50 | MBR-10X14.5 | 1480*700*1400 | 14 | 140 |

| 60 | MBR-10X16 | 1680*700*1400 | 16 | 160 |

| 80 | MBR-10X22 | 2280*700*1400 | 22 | 220 |

| 100 | MBR-10X27 | 2780*700*1400 | 27 | 270 |

| 80 | MBR-15X14 | 1580*700*1900 | 14 | 210 |

| 100 | MBR-15X18 | 1880*700*1900 | 18 | 270 |

| 120 | MBR-15X22 | 2280*700*1900 | 22 | 330 |

| 150 | MBR-15X27 | 2800*700*1900 | 27 | 405 |

| 200 | MBR-15X36 | 1880*1380*1900 | 36 | 540 |

| 250 | MBR-15X36 | 2400*1380*1900 | 46 | 690 |

| 300 | MBR-15X54 | 2800*1380*1900 | 54 | 810 |

Product advantages

Low energy consumption and high efficiency

Low pressure and high flux, stable operation

The operating flux is increased by 40%, and the demand for chemical agents is low

Long service life

High mechanical strength, no breakage of fibers, high hydrophilicity, and slow flux decay

Long cleaning cycle

The pollution rate is reduced by 60%, and it has strong resistance to decay

The concentration of chemicals for cleaning is increased by 200%

Easy to clean and restore

Safe and reliable water production

Uniform pore size, high porosity, high stripping strength, and no peeling

Upgraded membrane rack

Quick plug-in installation, and convenient maintenance and cleaning

A pulsed aeration box for uniform air and water scrubbing

Various optional solutions to meet different needs

Hydrophilic and Moisturizing Membrane

The reinforced composite PVDF membrane is made from hydrophilic - modified PVDF raw materials, giving the membrane good hydrophilic properties. There is no need for on - site hydrophilic treatment. However, if the membrane is not put into use immediately after installation, or if it needs to be parked for a certain period during use, please ensure that the membrane is immersed in water or kept in a wet condition at all times.

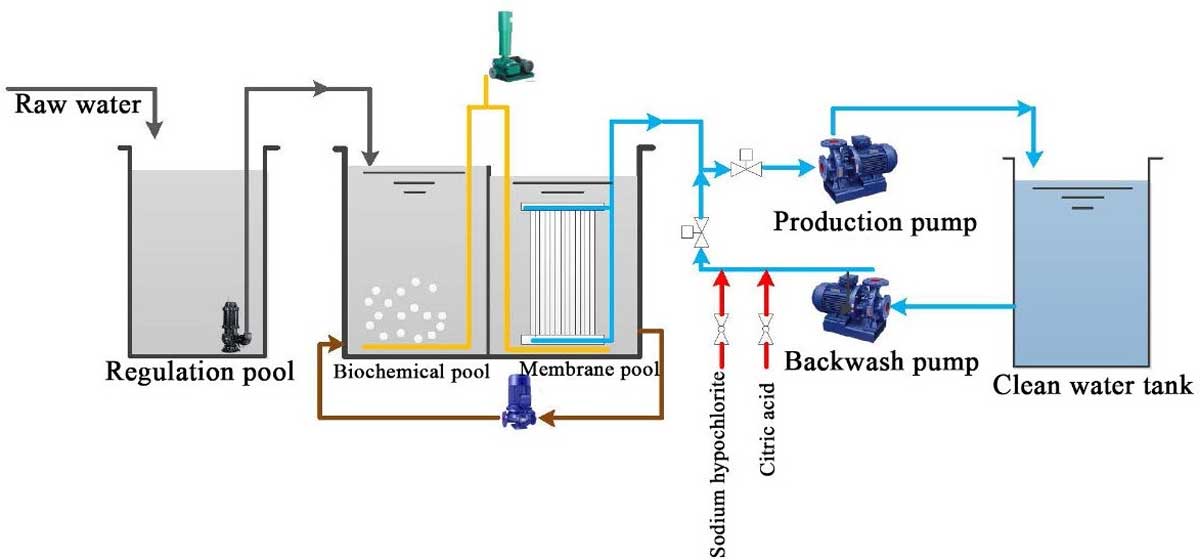

Maintenance of Membrane Flux and Membrane Cleaning

The diaphragm aeration system is constructed using perforated aeration. The bubbles from aeration and the water flow work together to make the membrane vibrate fully, achieving self - cleaning of the membrane. An intermittent operation mode is used, where the self - priming pump sucks for 10 to 12 minutes and then stops for 2 to 3 minutes. This can effectively prevent the clogging of the membrane pores and ensure the long - term and stable operation of the membrane separation. When used for the first time, the microbiological culture in the biochemical pool achieves good activity, and the membrane is only put into operation when the viscosity is low.