+86 13600513715

+86 13600513715

01

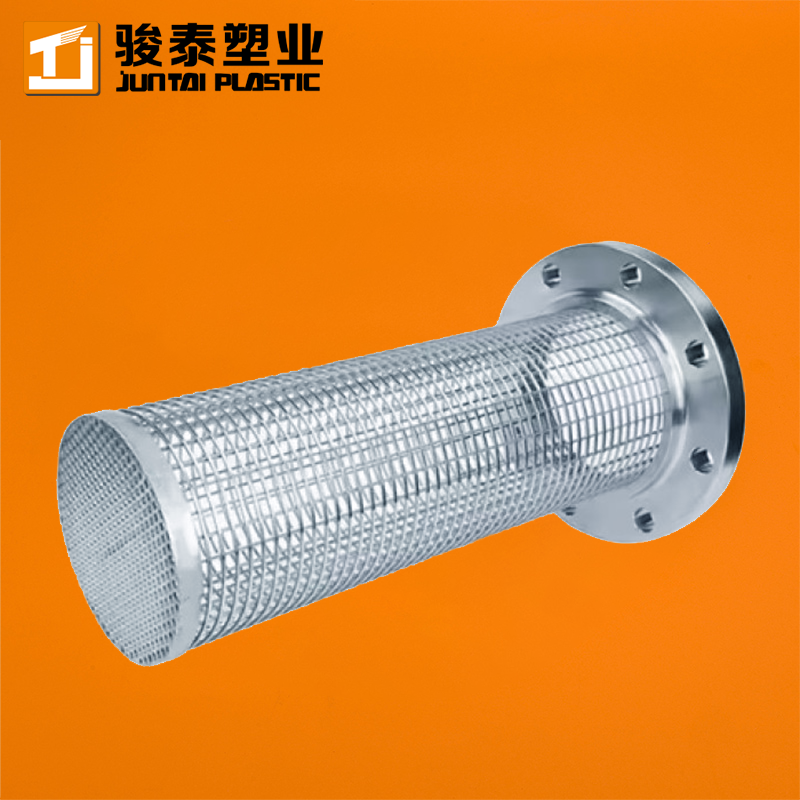

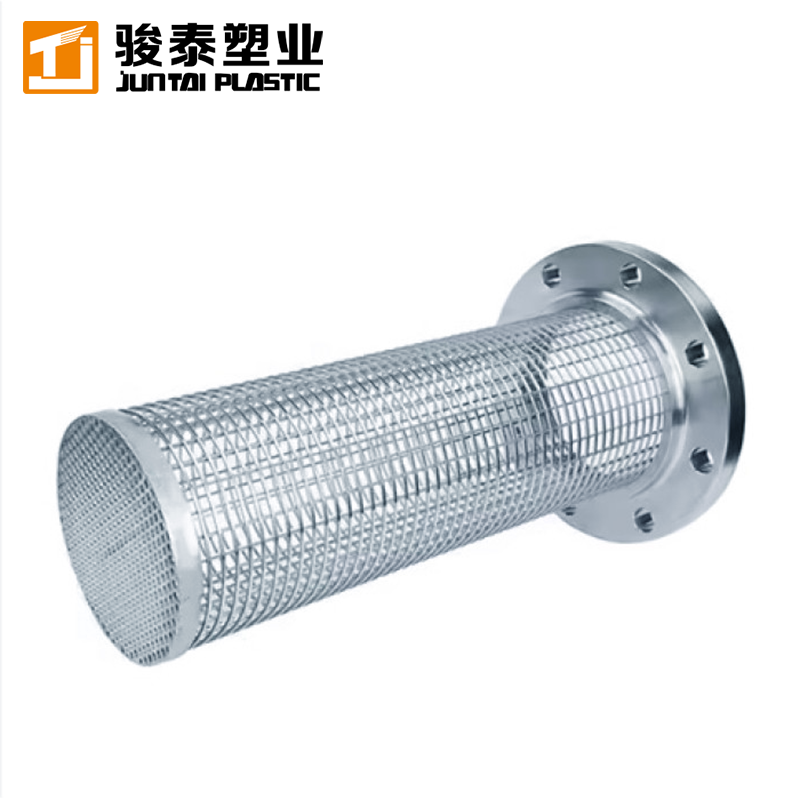

MBBR Media Screens for Retention Bio Carrier Seives

Product Parameters

|

No. |

Model |

Diameter(mm) |

Length(mm) |

Aperture size (mm) |

Wedge wire diameter(mm) |

|

1 |

HS-150 |

DN150 |

200~4000 |

5~12 |

2~3 |

|

2 |

HS-200 |

DN200 |

200~4000 |

5~12 |

2~3 |

|

3 |

HS-250 |

DN250 |

200~4000 |

5~12 |

2~3 |

|

4 |

HS-300 |

DN300 |

200~4000 |

5~12 |

2~3 |

|

5 |

HS-350 |

DN350 |

200~4000 |

5~12 |

2~3 |

|

6 |

HS-400 |

DN400 |

200~4000 |

5~12 |

2~3 |

|

7 |

HS-450 |

DN450 |

200~4000 |

5~12 |

2~3 |

|

8 |

HS-500 |

DN500 |

200~4000 |

5~12 |

2~3 |

|

9 |

HS-550 |

DN550 |

200~4000 |

5~12 |

2~3 |

|

10 |

HS-600 |

DN600 |

200~4000 |

5~12 |

2~3 |

Product Features

MBBR Retention Screens are integral components in Moving Bed Biofilm Reactor (MBBR) systems, designed to effectively retain biofilm carriers within the reactor, thereby enhancing the efficiency and stability of wastewater treatment processes.

Product Features:

High-Quality Material: Constructed from premium stainless steel sintered wire mesh, these screens offer exceptional corrosion resistance and durability, ensuring a long service life even in harsh wastewater environments.

Precision Engineering: Manufactured with meticulous attention to detail, the screens feature uniform mesh openings that facilitate optimal fluid flow and efficient filtration.

Safety Design: The screens are designed with smooth edges and a burr-free surface, minimizing the risk of damage to biofilm carriers and ensuring safe handling during installation and maintenance.

Advantages

Uniform Permeability: The consistent permeability of the screens ensures even distribution of fluids during filtration, enhancing treatment efficiency and consistency.

Excellent Fluid Flow: The screens allow for free passage of fluids, reducing resistance and effectively preventing the formation of bubbles or voids, ensuring smooth fluid movement.

High Flow Rate: The design enables processing of larger volumes of fluid within the same timeframe, increasing productivity and reducing time costs.

Effective Impurity Capture: The screens efficiently capture and intercept impurities, particles, or contaminants in the fluid, ensuring its purity and safety.

Efficient Filtration Performance: The screens effectively remove suspended solids, microorganisms, or harmful substances from the fluid, ensuring the quality and safety of the final product.

Applications in Power Plant Wastewater Treatment

Filler Retention: The primary function of the retention screens is to prevent biofilm carriers in the MBBR system from being lost with the effluent. By positioning the screens at the outlet, the carriers are effectively retained, allowing them to continue circulating and being utilized in the reactor, thereby promoting sustained biofilm growth and efficient system operation.

Clogging Prevention: High-quality retention screens prevent biofilm carriers or larger particles from clogging the outlet, ensuring smooth water flow, reducing system maintenance and cleanup, and maintaining treatment efficiency.

Enhanced Treatment Efficiency: Retention screens ensure that the biofilm carriers remain in the reactor long enough for the biofilm to degrade the contaminants in the wastewater, thus improving treatment efficiencies. Longer retention time contributes to more efficient organic matter degradation and pollutant removal.

Extended Carrier Life: By preventing loss of biofilm carriers, the screens extend their lifespan, reduce the frequency of carrier replacement, and lower operating costs.

System Stability Maintenance: Retention screens maintain a stable amount of biofilm carriers and biofilm in the reactor, ensuring stable operation and consistent treatment results, especially during load changes or unexpected conditions.

Prevention of Excessive Biofilm Growth: The screens help control the movement of the carriers in the reactor, preventing excessive biofilm growth and carrier entanglement, thus ensuring efficient operation of the system.

Incorporating high-quality MBBR Retention Screens into wastewater treatment systems enhances operational efficiency, reduces maintenance requirements, and ensures consistent treatment performance, making them a valuable component in modern wastewater management.