+86 13600513715

+86 13600513715

Plastic Metal Pall Ring Media for Cooling Tower Filler

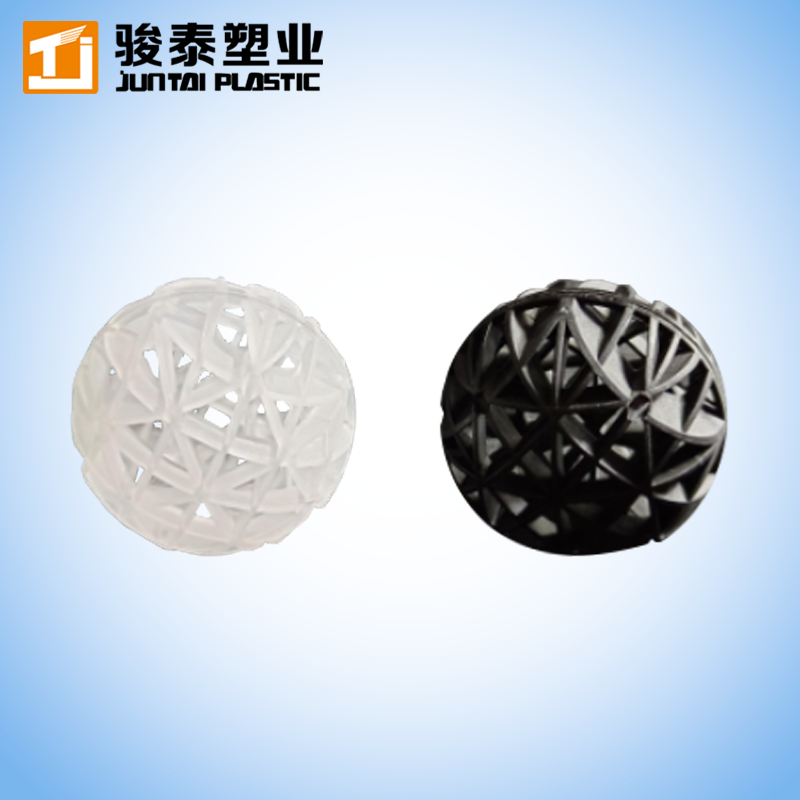

MBBR Media Of Different Products

| MBBR04 | MBBR19 | MBBR37 | MBBR64 |

| Size:Φ11*7mm | Size:Φ25*12mm | Size:Φ25*4mm | Size:Φ25*4mm |

| Hole Numbers:04 | Hole Numbers:19 | Hole Numbers:37 | Hole Numbers:64 |

| Weight:125Kg/CBM | Weight:95KG/CBM | Weight:110Kg/CBM | Weight:125Kg/CBM |

| Surface Area:>900m2/m3 | Surface Area:>650m2/m3 | Surface rea:>800m2/m3 | Surface Area:>1200m2/m3 |

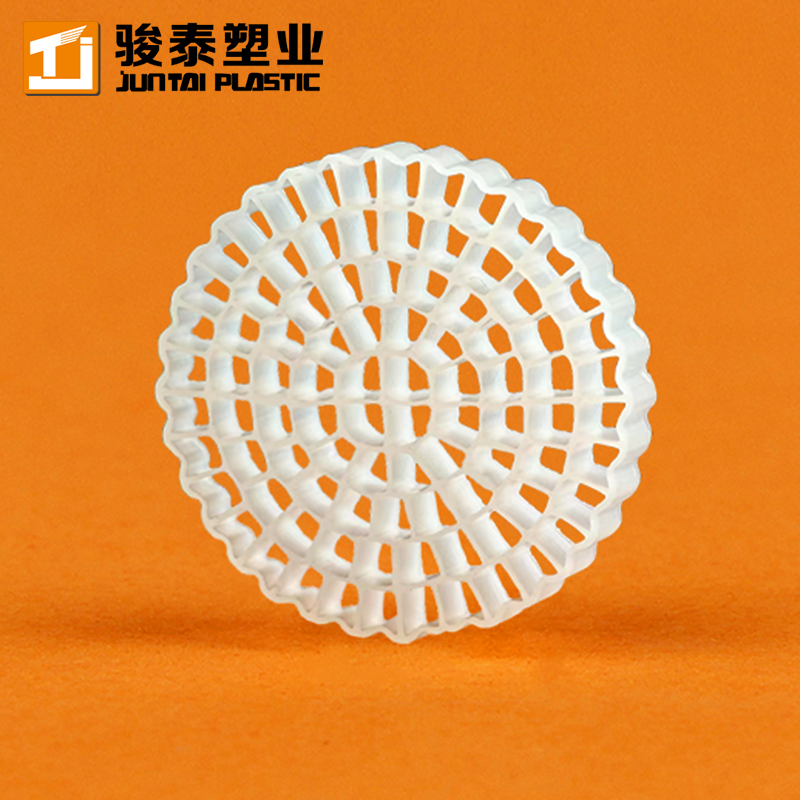

Comparison Of Product Parameters

| Item No. | Size | Surface Area | Rooms |

| MBBR04 | 11mm*7mm | >900m2/m3 | 4 rooms |

| MBBR05 | 11mm*7mm | >1000m2/m3 | 5 rooms |

| MBBR06 | 16mm*10mm | >800m2/m3 | 6 rooms |

| MBBR08 | 10mm*5mm | >3500m2/m3 | 8 rooms |

| MBBR19 | 25mm*12mm | >650m2/m3 | 19 rooms |

| MBBR37 | 25mm*12mm | >800m2/m3 | 37rooms |

| MBBR40 | 15mm*15mm | >900m2/m3 | 40 rooms |

| MBBR61 | 25mm*4mm | >1250m2/m3 | 61 rooms |

| MBBR64 | 25mm*4mm | >1200m2/m3 | 64 rooms |

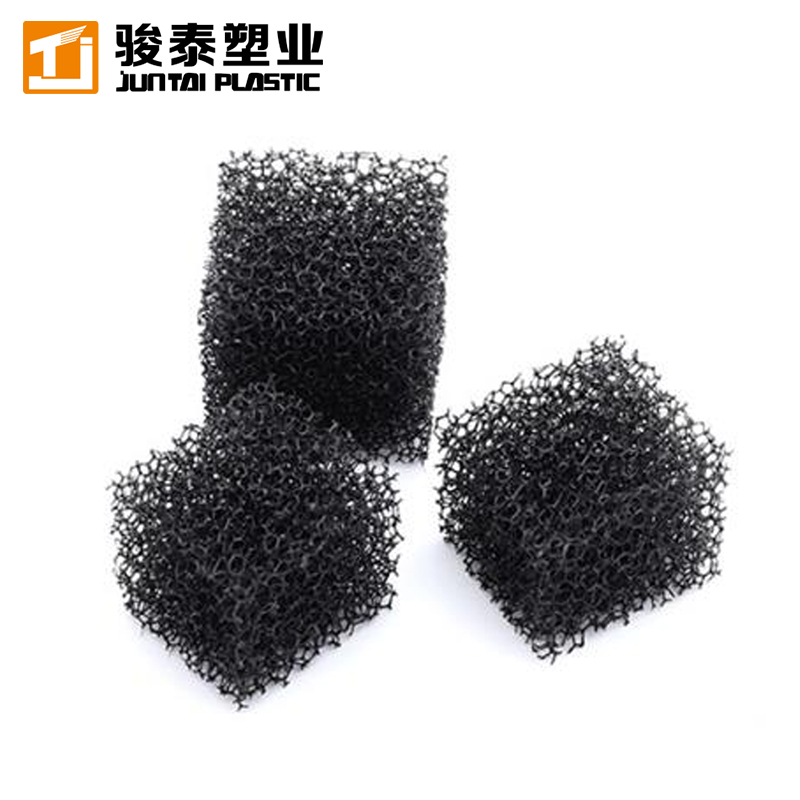

Quality Materials for Safe and Durable MBBR Media

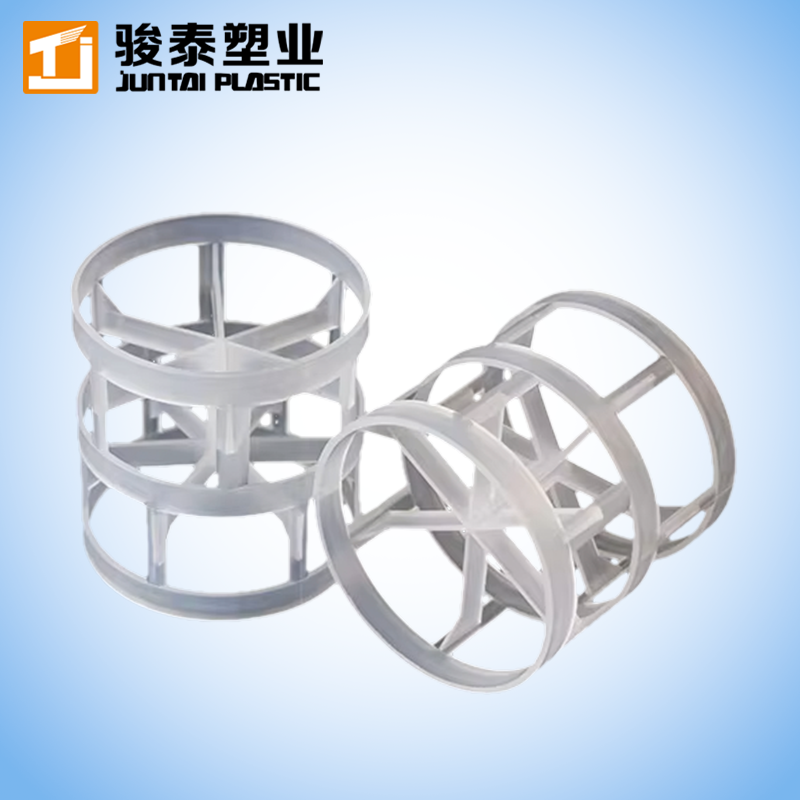

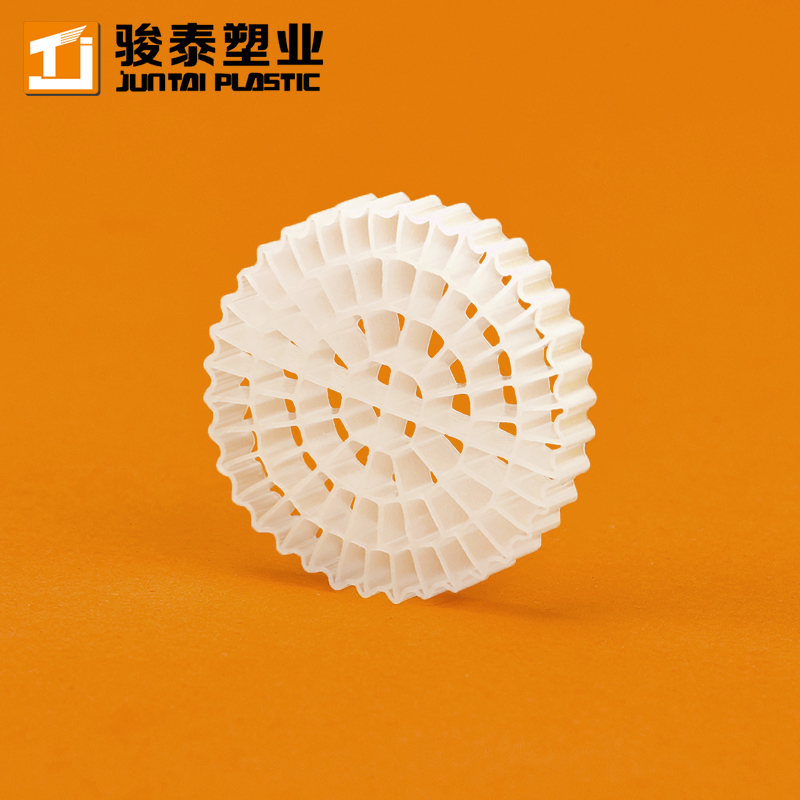

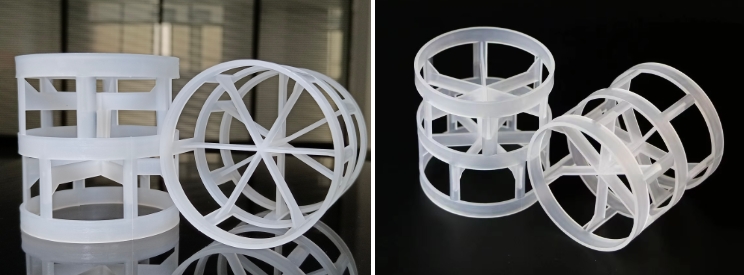

PALL RING

it was invented by German BASF, the first generation Plastic Random packing. Compared with the Raschig ring, the most important improvement is the increase of two rows of inward ligules.

Advantages of Juntai Pall Rings:

1. High void ratio: They occupy a smaller volume in the tower, leaving more space for the flow of gases and liquids.

2. Low-pressure drop: Our Cytech PPall ring design results in a low-pressure drop across the packing, which saves energy.

3. Uniform distribution: The shape of the palladium ring promotes uniform distribution of gas and liquid throughout the packing, thus improving mass transfer efficiency.

4. Improved Liquid Retention: Having a unique geometry improves liquid retention compared to other types of random packing.

5. High mechanical strength: Pall rings are robust and durable, making them less likely to be damaged during installation or operation.

6. Versatility: Pall rings can be used in a wide range of applications, including chemical treatment, wastewater treatment, and air pollution control.

Application

-

Food & Beverage Wastewater Treatment

-

Dairy & Cheese Industry Wastewater Treatment

-

Chemical Industry Wastewater Treatment

-

Textile Industry Wastewater Treatment

-

Municipal Wastewater Treatment

-

Recirculating Aquaculture System