+86 13600513715

+86 13600513715

Wholesale MBBR Bio Filter Media in Wastewater Treatment

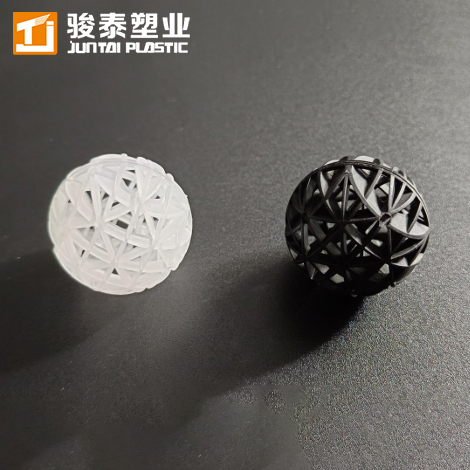

MBBR Media Of Different Products

| MBBR04 | MBBR19 | MBBR37 | MBBR64 |

| Size:Φ11*7mm | Size:Φ25*12mm | Size:Φ25*4mm | Size:Φ25*4mm |

| Hole Numbers:04 | Hole Numbers:19 | Hole Numbers:37 | Hole Numbers:64 |

| Weight:125Kg/CBM | Weight:95KG/CBM | Weight:110Kg/CBM | Weight:125Kg/CBM |

| Surface Area:>900m2/m3 | Surface Area:>650m2/m3 | Surface rea:>800m2/m3 | Surface Area:>1200m2/m3 |

Comparison Of Product Parameters

| Item No. | Size | Surface Area | Rooms |

| MBBR04 | 11mm*7mm | >900m2/m3 | 4 rooms |

| MBBR05 | 11mm*7mm | >1000m2/m3 | 5 rooms |

| MBBR06 | 16mm*10mm | >800m2/m3 | 6 rooms |

| MBBR08 | 10mm*5mm | >3500m2/m3 | 8 rooms |

| MBBR19 | 25mm*12mm | >650m2/m3 | 19 rooms |

| MBBR37 | 25mm*12mm | >800m2/m3 | 37rooms |

| MBBR40 | 15mm*15mm | >900m2/m3 | 40 rooms |

| MBBR61 | 25mm*4mm | >1250m2/m3 | 61 rooms |

| MBBR64 | 25mm*4mm | >1200m2/m3 | 64 rooms |

Quality Materials for Safe and Durable MBBR Media

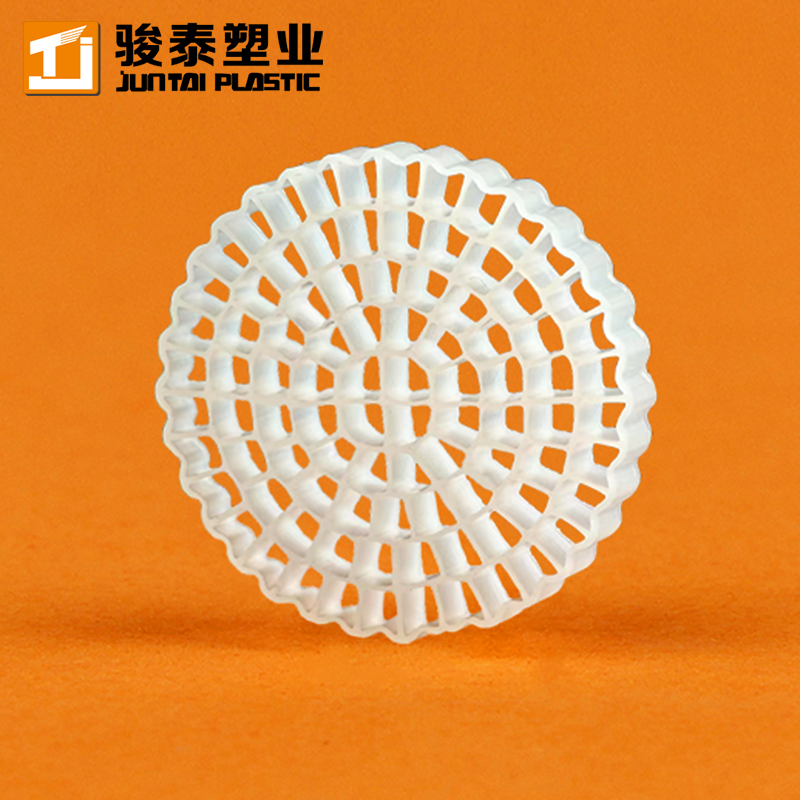

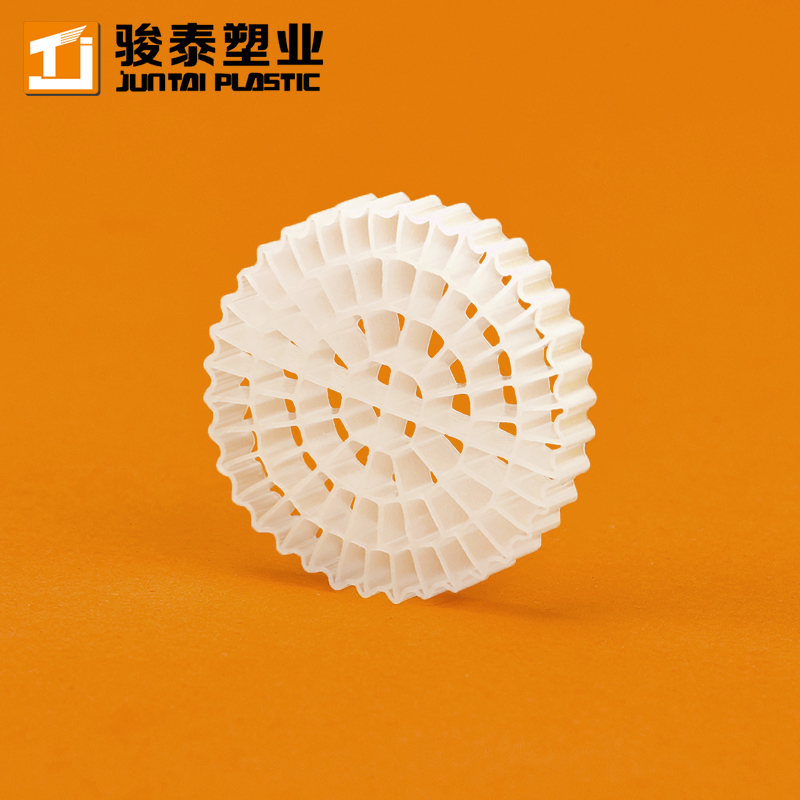

1. Advanced 3D Biofilm Matrix Technology

Hexagonal Honeycomb Architecture: Proprietary lattice design delivers 800-1,500 m²/m³ effective surface area, enabling stratified colonization of nitrifying, denitrifying, and phosphorus-accumulating bacteria.

Shock Load Resistance: Self-cleaning hydrodynamic shear forces maintain 95%+ porosity under COD fluctuations up to 8,000 mg/L·d, ideal for chemical, pharmaceutical, and refinery wastewater.

2. Eco-Engineered for Sustainable Performance

UV-Stabilized Nano-HDPE Composite: Reinforced with inorganic hydrophilic additives, withstands pH 0.5-14, extreme temps (-40°C to 95°C), and 20+ years of UV exposure—2X longer than conventional media.

Energy-Smart Aeration: Vortex-inducing fins boost oxygen transfer efficiency (OTE) to 38%, reducing energy use by 35-50% vs. standard carriers—saving 550,000 kWh/year for 10,000 m³/day plants.

3. Simultaneous Nitrogen & Phosphorus Removal

Dual-Density Zoning System: Aerobic (0.94 g/cm³) and anoxic (1.03 g/cm³) zones enable single-tank SND (simultaneous nitrification-denitrification), achieving 88% TN removal and 18 mg/g P adsorption.

Biofilm Accelerator Coating: Enzyme-embedded surface reduces biofilm maturation time by 30%, even in low-temp (8°C) or high-salinity (5% NaCl) environments.

4. Intelligent Plug-and-Play Solutions

Customizable Configurations: Modular media (8-60 mm diameter) with 30-70% fill ratio adaptability, cutting retrofit time by 65% in legacy activated sludge systems.

AI-Driven Process Control: IoT-enabled biofilm thickness sensors + machine learning optimize DO levels and predict maintenance, slashing OPEX by 45%.

5. Globally Trusted Safety & Compliance

Aquaculture-Safe Certification: FDA-compliant & RoHS-tested material eliminates microplastic leaching—critical for RAS systems and potable water reuse projects.

Proven Cross-Industry Success: 600+ installations worldwide, including Saudi Aramco’s Oily Water Treatment, Canadian Arctic Mining Effluent, and EU Smart City WWTPs.

-

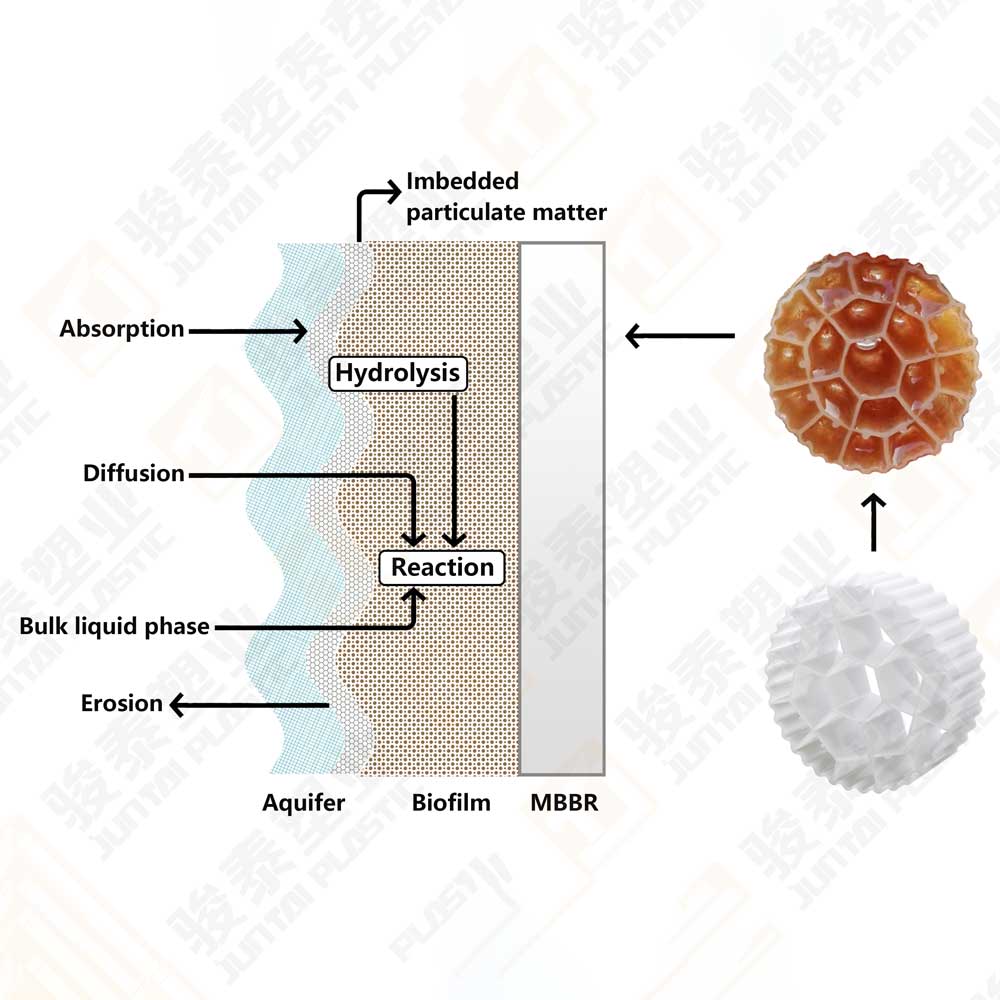

MBBR Filter Media Working Principle

-

MBBR carrier deployment site

-

Biofilm formation on MBBR carriers

Application

-

Food & Beverage Wastewater Treatment

-

Dairy & Cheese Industry Wastewater Treatment

-

Chemical Industry Wastewater Treatment

-

Textile Industry Wastewater Treatment

-

Municipal Wastewater Treatment

-

Recirculating Aquaculture System