+86 13600513715

+86 13600513715

01

MBBR Wastewater Treatment Process for Aquaculture Wastewater Secondary Treatment

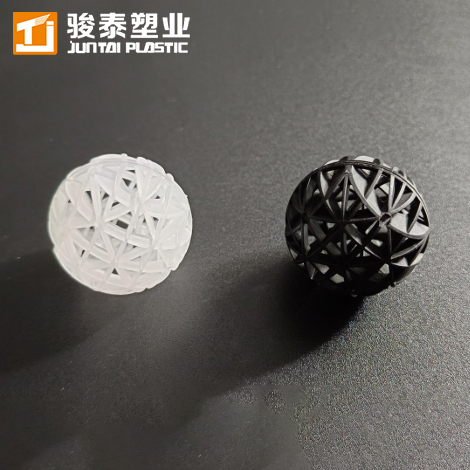

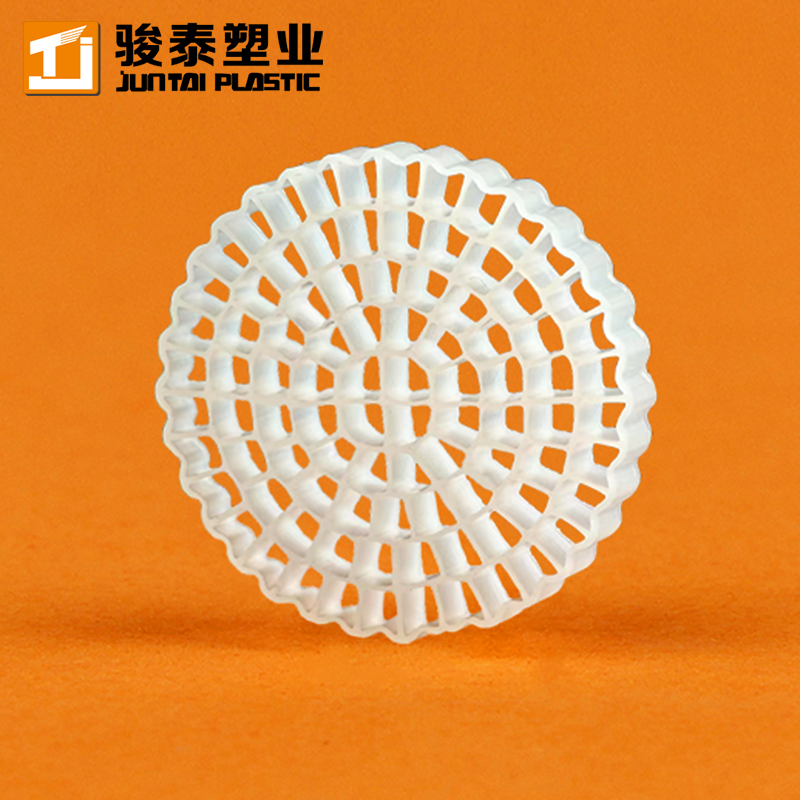

MBBR Media Of Different Products

| MBBR04 | MBBR19 | MBBR37 | MBBR64 |

| Size:Φ11*7mm | Size:Φ25*12mm | Size:Φ25*4mm | Size:Φ25*4mm |

| Hole Numbers:04 | Hole Numbers:19 | Hole Numbers:37 | Hole Numbers:64 |

| Weight:125Kg/CBM | Weight:95KG/CBM | Weight:110Kg/CBM | Weight:125Kg/CBM |

| Surface Area:>900m2/m3 | Surface Area:>650m2/m3 | Surface rea:>800m2/m3 | Surface Area:>1200m2/m3 |

Comparison Of Product Parameters

| Item No. | Size | Surface Area | Rooms |

| MBBR04 | 11mm*7mm | >900m2/m3 | 4 rooms |

| MBBR05 | 11mm*7mm | >1000m2/m3 | 5 rooms |

| MBBR06 | 16mm*10mm | >800m2/m3 | 6 rooms |

| MBBR08 | 10mm*5mm | >3500m2/m3 | 8 rooms |

| MBBR19 | 25mm*12mm | >650m2/m3 | 19 rooms |

| MBBR37 | 25mm*12mm | >800m2/m3 | 37rooms |

| MBBR40 | 15mm*15mm | >900m2/m3 | 40 rooms |

| MBBR61 | 25mm*4mm | >1250m2/m3 | 61 rooms |

| MBBR64 | 25mm*4mm | >1200m2/m3 | 64 rooms |

Quality Materials for Safe and Durable MBBR Media

The material used in MBBR biofilter media plays a crucial role in determining its performance, longevity, and ease of biofilm formation. A high-quality and pure material not only ensures a longer service life but also facilitates the rapid development of a stable biofilm, which is essential for the efficient operation of the system.

JUNTAI prioritizes the use of food-grade materials in the production of its MBBR media. This ensures that the material is free from harmful substances, such as heavy metals like lead and tin, as well as phthalates and plasticizers, which are known to pose significant health risks. Phthalates and plasticizers, in particular, have been linked to cancer and other serious illnesses in both humans and animals. This is especially critical in applications like fish farms, where the health of the aquatic life is paramount. Non-food-grade materials can contaminate the water, leading to health problems for the fish and potentially compromising the entire farming operation.

Moreover, the MBBR media produced by JUNTAI is made from 100% virgin HDPE (high-density polyethylene). This ensures that the media is durable and resistant to wear. In contrast, materials that incorporate recycled components, such as fillers like calcium carbonate or reused HDPE, are prone to brittleness. These inferior materials can easily break into small plastic fragments, which pose significant risks in both drinking water treatment and aquaculture settings. These tiny plastic particles are difficult to remove from water, and in some cases, there is no effective method for their removal. When fish or other aquatic organisms come into contact with water containing plastic debris, it can severely impact their health, growth, and overall well-being. The presence of such contaminants also poses potential health hazards to humans who consume the water or aquatic products.

In addition to the above, JUNTAI's MBBR media is designed with UV protection, extending its lifespan to an impressive 20 years. In aquatic systems, such as aerobic and anaerobic tanks, the media is often exposed to direct sunlight for extended periods. Without proper UV protection, the material can degrade under the harsh sunlight, leading to breakage and the release of harmful plastic debris into the water. This, in turn, creates a vicious cycle of contamination, exacerbating the risks mentioned earlier.

In summary, the choice of material for MBBR biofilter media is a critical factor that affects both the efficiency and safety of water treatment systems. JUNTAI’s commitment to using food-grade, virgin HDPE with UV protection ensures that its MBBR media is not only high-performance but also safe for both aquatic life and human health, guaranteeing long-lasting reliability in various applications.

-

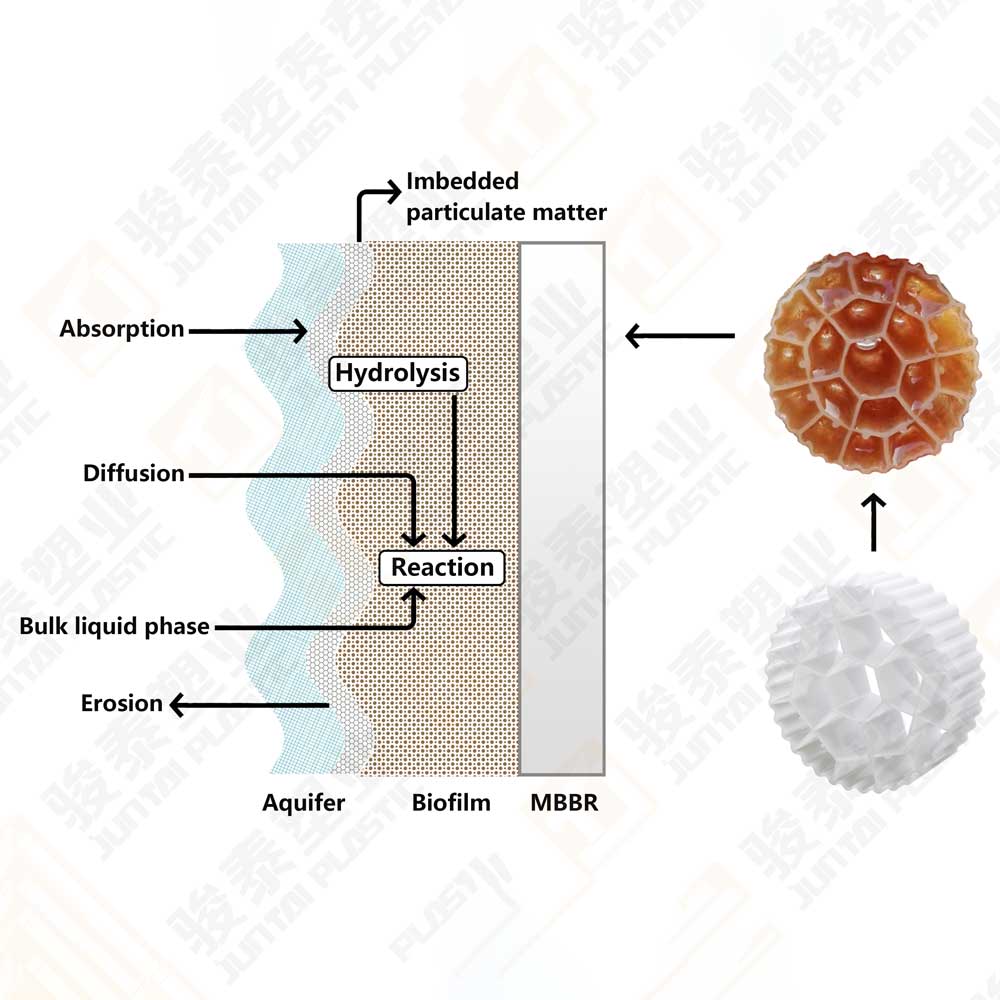

MBBR Filter Media Working Principle

-

MBBR carrier deployment site

-

Biofilm formation on MBBR carriers

Application

-

Food & Beverage Wastewater Treatment

-

Dairy & Cheese Industry Wastewater Treatment

-

Chemical Industry Wastewater Treatment

-

Textile Industry Wastewater Treatment

-

Municipal Wastewater Treatment

-

Recirculating Aquaculture System

Product Features

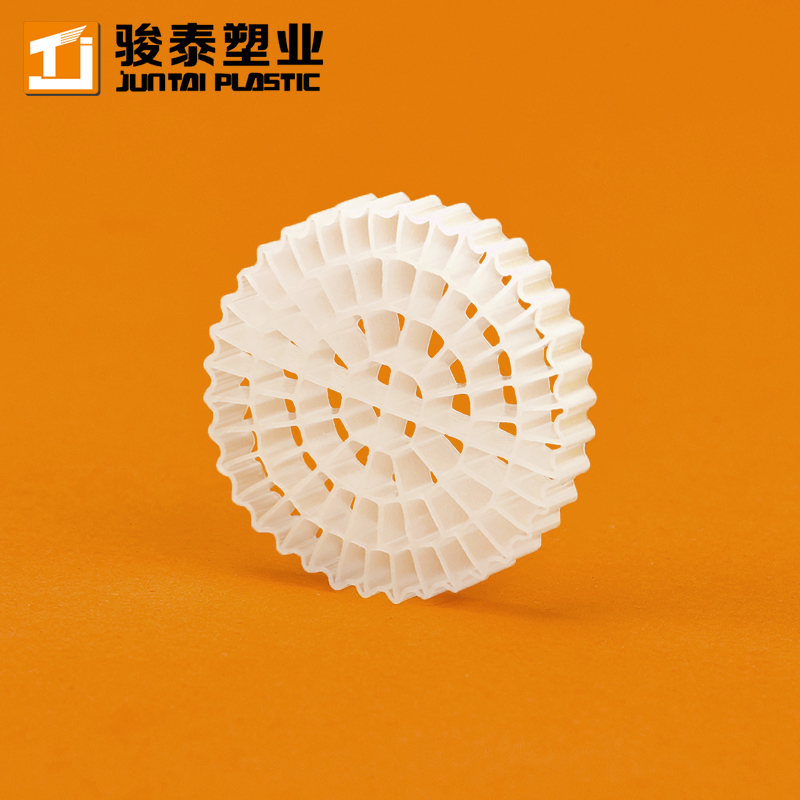

Manufacturing the ideal MBBR Biofilm Carrier

Achieving the ideal MBBR media involves a combination of precision design, high-quality machinery, and careful control of production processes. Every step, from material selection to cooling, contributes to the final performance and durability of the biofilm carrier.

Precision Machinery and Cooling Control

A well-equipped production facility is essential for creating perfect MBBR media. The cooling system must be carefully controlled to ensure the material maintains its shape after exiting the mold, preventing any deformation that could compromise its functionality.

Optimal Design for Shape Retention

The design of the media should be robust enough to maintain its integrity throughout its operational life, even under the stresses of aeration and water flow. Proper design is crucial for long-lasting performance.

Material Strength and Durability

The biofilm carrier must be durable enough to withstand frequent use without breaking. A strong media will endure continuous aeration and remain intact, ensuring consistent filtration performance over time.

Use of Virgin HDPE

Only 100% virgin HDPE should be used in production, free of fillers or recycled materials. Using inferior materials may lower costs initially, but the result will be a fragile product prone to cracking, significantly reducing the lifespan and efficiency of the MBBR system.

Non-Toxic and Safe Materials

For applications involving drinking water, aquaculture, or fish farming, the materials must be non-toxic and free of harmful substances like phthalates and carcinogens. This ensures that the biofilm carrier will not contaminate the water or harm aquatic life.

Advanced Cooling and Cutting Systems

A cooling system longer than 12 meters is required to maintain consistent shape and quality across all biofilm carriers. Additionally, a high-speed cutting system is essential for achieving flat, uniform surfaces on the media, which enhances the efficiency of biofilm growth and overall system performance.