+86 13600513715

+86 13600513715

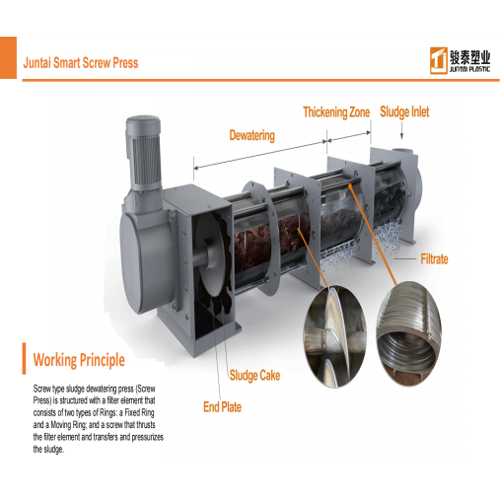

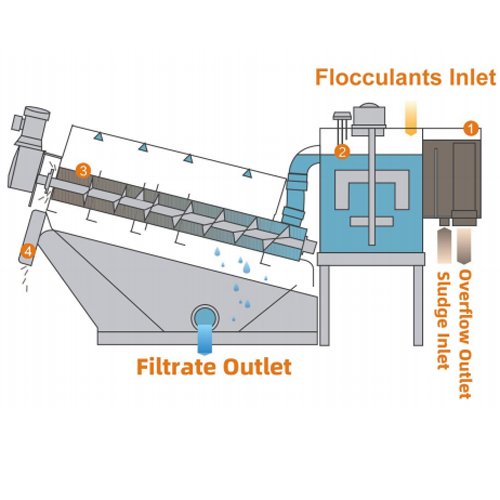

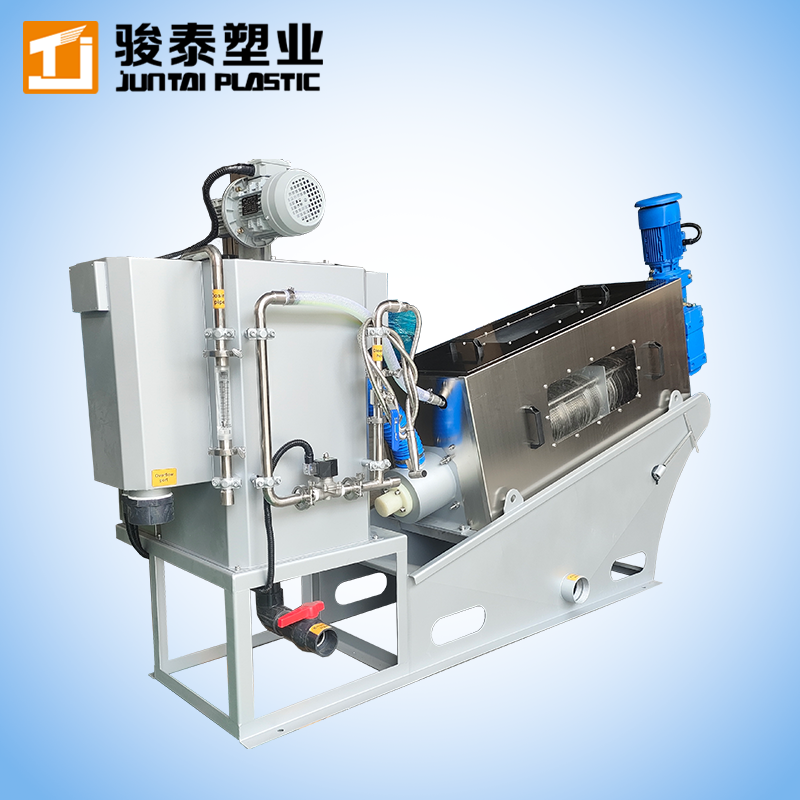

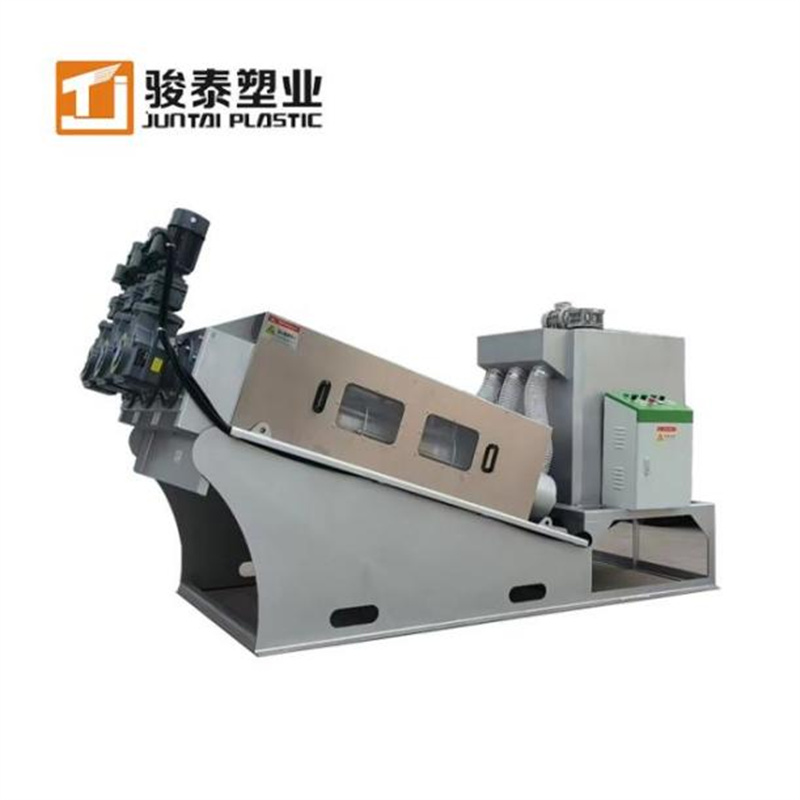

Efficient Dewatering Sludge Screw Press Machine for Sale

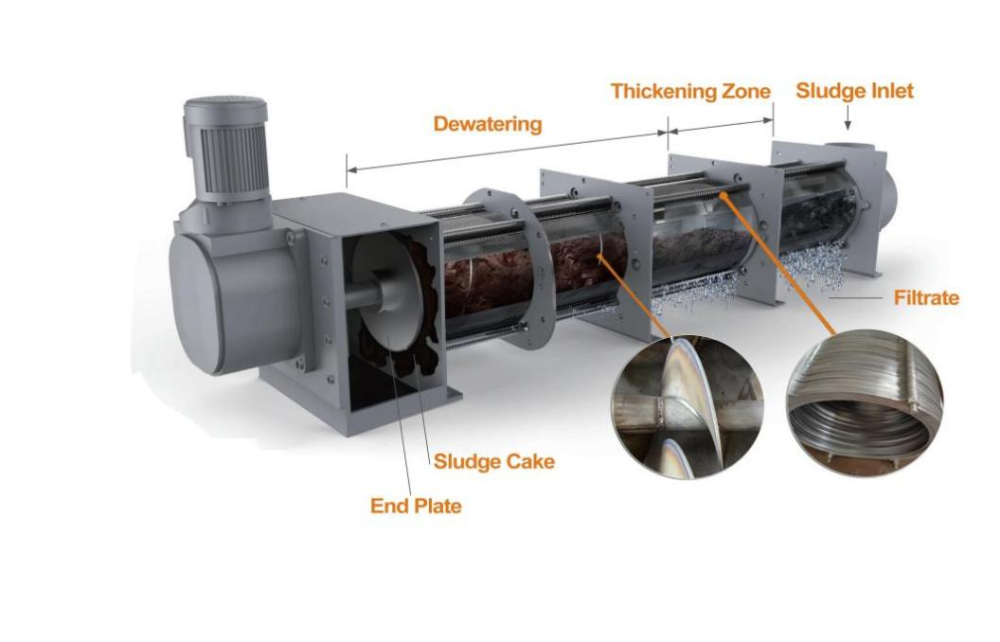

Working Principle

product details

-

Steel Cover and PMMA Windows make safer

Stainless steel Cover with two handles on the above ofthe main boby, Glass windows in both, The cover makethe equipment safer and the worker safter whenrunning.In addition, the steel plate cover can effectivelyprevent dust from falling in and affecting the service life. -

Steel Sprinker System got longer life

The Sprinker system is very important to the dewateringsystem, it is the most easy to demager system when useall of the parts of Juntai Screw Press sprinker system aremade by SS304, including the pipe, the inject and thenozzel, it will never need replace the spayer nozzel -

Detailing Guaratee Quality

Juntai fucus on every detailing of the Screw Press, suchas the snoothy surface, the cable protect, the wire stableRadius and snoothy angles, welded line and all thedetailings, Juntai try to do as best as we can ,and this isalso a way to ensure the quality -

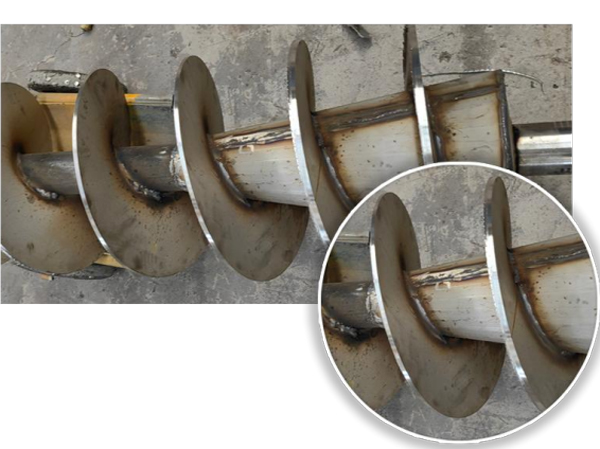

Cobalt Alloy Wear Layer Make Screws Harder

All of Screws of Juntai Dewatering machine are welded acabalt Alloy Wear layer which are much harder than thatof SS304, and with the Aobalt Alloy waer layer, the screwis harder and canbe used many more years -

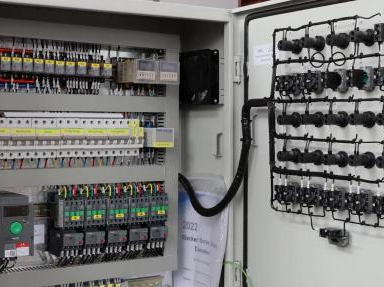

French Schneider Electric Control Cabinet

JUNTAI dewatering machine is installed with French schneider electric control box, this high quality control box can better ensure the safety. -

Pressure Water Gun With Fiberglass Hose make clean Easier

JUNTAI Screw Press has a pressure water Gun with high quality strengthen hose, which can clean any part of the machine at easier.

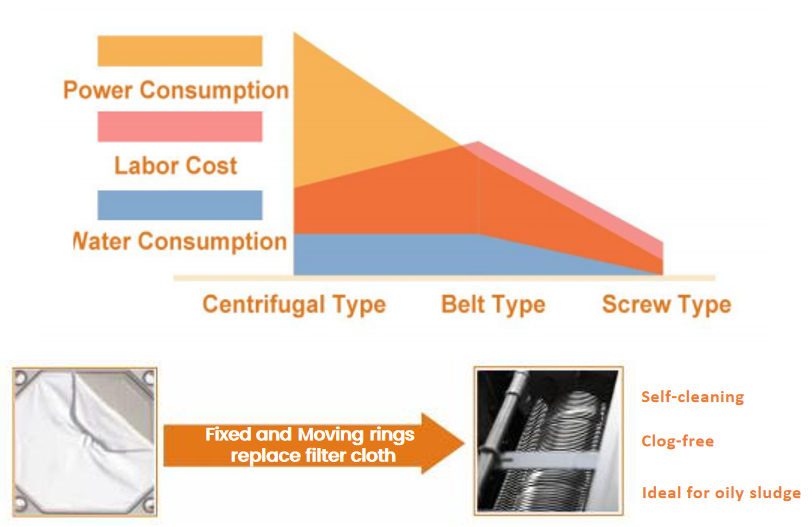

JUNTAI Screw Press Technology Advantage

JUNTAI Technology Advantage 6

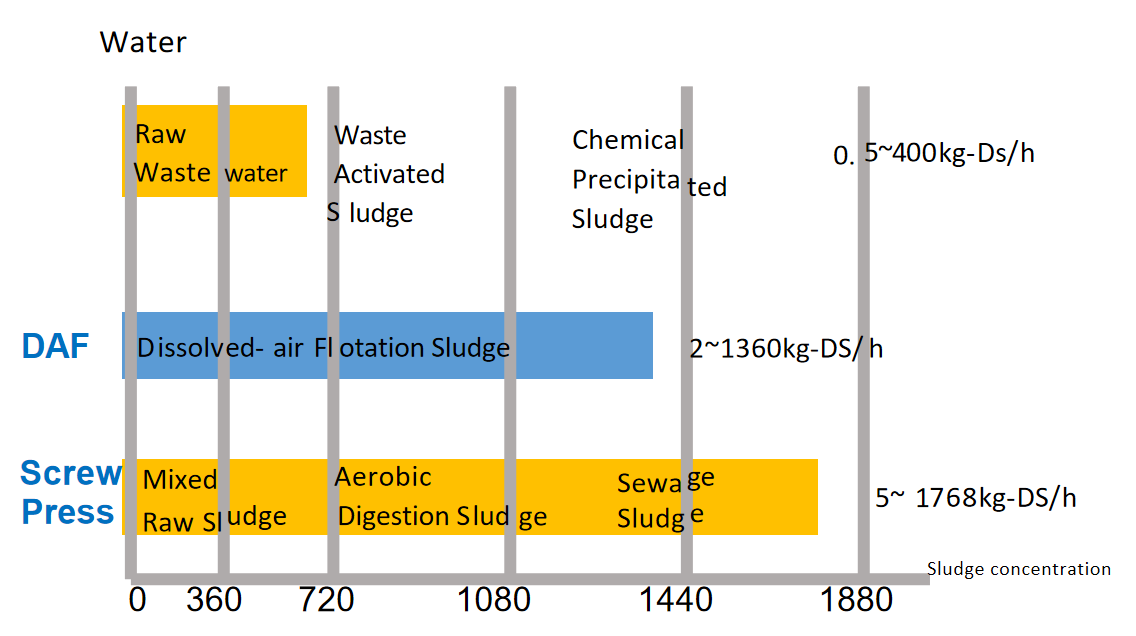

Juntai Screw Press can deal with waste water cover Sludge concentration 0.5 to 1768KG/DS/h Water

|

Type |

DS Standard |

Theoretical Reference For Sludge Treatment Volume |

||||||

|

Processing Volume |

(specific treatment volume is determined by the flocculation effect ofsludge and chemicals) |

|||||||

|

Low concentration--High concentration |

2000mg/L |

5000mg/L |

10000mg/L |

20000mg/L |

25000mg/L |

50000mg/L |

||

|

Sludge Treatment Capactiy |

Kg/h |

Kg/h |

M3/h |

M3/h |

M3/h |

M3/h |

M3/h |

M3/h |

|

JT-131 |

~6 |

~10 |

~3 |

~1.2 |

~1 |

~0.5 |

~0.4 |

~0.2 |

|

JT-132 |

~12 |

~20 |

~6 |

~2.4 |

~2 |

~1 |

~0.8 |

~0.4 |

|

JT-201 |

~9 |

~15 |

~4.5 |

~1.8 |

~1.5 |

~0.75 |

~0.6 |

~0.3 |

|

JT-202 |

~18 |

~30 |

~9 |

~3.6 |

~3 |

~1.5 |

~1.2 |

~0.6 |

|

JT-301 |

~30 |

~50 |

~15 |

~6 |

~5 |

~2.5 |

~2 |

~1 |

|

JT-302 |

~60 |

~100 |

~30 |

~12 |

~10 |

~5 |

~4 |

~2 |

|

JT-303 |

~90 |

~150 |

~45 |

~18 |

~15 |

~7.5 |

~6 |

~3 |

|

JT-401 |

~90 |

~150 |

~45 |

~18 |

~15 |

~7.5 |

~6 |

~3 |

|

JT-402 |

~180 |

~300 |

~90 |

~36 |

~30 |

~15 |

~12 |

~6 |

|

JT-403 |

~270 |

~450 |

~135 |

~54 |

~45 |

~22.5 |

~18 |

~9 |

|

JT-404 |

~360 |

~600 |

~180 |

~72 |

~60 |

~30 |

~24 |

~12 |

products parameter

|

Type |

DS Standard |

Theoretical Reference For Sludge Treatment Volume |

||||||

|

Processing Volume |

(specific treatment volume is determined by the flocculation effect ofsludge and chemicals) |

|||||||

|

Low concentration--High concentration |

2000mg/L |

5000mg/L |

10000mg/L |

20000mg/L |

25000mg/L |

50000mg/L |

||

|

Sludge Treatment Capactiy |

Kg/h |

Kg/h |

M3/h |

M3/h |

M3/h |

M3/h |

M3/h |

M3/h |

|

JT-131 |

~6 |

~10 |

~3 |

~1.2 |

~1 |

~0.5 |

~0.4 |

~0.2 |

|

JT-132 |

~12 |

~20 |

~6 |

~2.4 |

~2 |

~1 |

~0.8 |

~0.4 |

|

JT-201 |

~9 |

~15 |

~4.5 |

~1.8 |

~1.5 |

~0.75 |

~0.6 |

~0.3 |

|

JT-202 |

~18 |

~30 |

~9 |

~3.6 |

~3 |

~1.5 |

~1.2 |

~0.6 |

|

JT-301 |

~30 |

~50 |

~15 |

~6 |

~5 |

~2.5 |

~2 |

~1 |

|

JT-302 |

~60 |

~100 |

~30 |

~12 |

~10 |

~5 |

~4 |

~2 |

|

JT-303 |

~90 |

~150 |

~45 |

~18 |

~15 |

~7.5 |

~6 |

~3 |

|

JT-401 |

~90 |

~150 |

~45 |

~18 |

~15 |

~7.5 |

~6 |

~3 |

|

JT-402 |

~180 |

~300 |

~90 |

~36 |

~30 |

~15 |

~12 |

~6 |

|

JT-403 |

~270 |

~450 |

~135 |

~54 |

~45 |

~22.5 |

~18 |

~9 |

|

JT-404 |

~360 |

~600 |

~180 |

~72 |

~60 |

~30 |

~24 |

~12 |

JUNTAI Screw Press Advantages