+86 13600513715

+86 13600513715

01

High Quality MBBR Mixing Bio Media Mixer for MBBR Tank

Low Speed Mixer Performance Parameters

| Model | Power (KW) | Electrode | Rated current (A) | Speed (r/min) | Quantity (set) | Diameter (mm) | Threst (N) | Weight (Kg) |

| JUNTAIMIXER3/4 | 3 | 4 | 6.6 | 420 | 2 | 400 | 1400 | 75 |

| JUNTAIMIXER4/4 | 4 | 4 | 8.6 | 420 | 2 | 550 | 1800 | 85 |

| JUNTAIMIXER5.5/4 | 5.5 | 4 | 11.8 | 420 | 2 | 550 | 2100 | 90 |

| JUNTAIMIXER7.5/4 | 7.5 | 4 | 15.5 | 420 | 2 | 620 | 2600 | 100 |

| JUNTAIMIXER11/4 | 11 | 4 | 24 | 420 | 2 | 750 | 3100 | 120 |

| JUNTAIMIXER15/4 | 15 | 4 | 33 | 420 | 2 | 800 | 3500 | 150 |

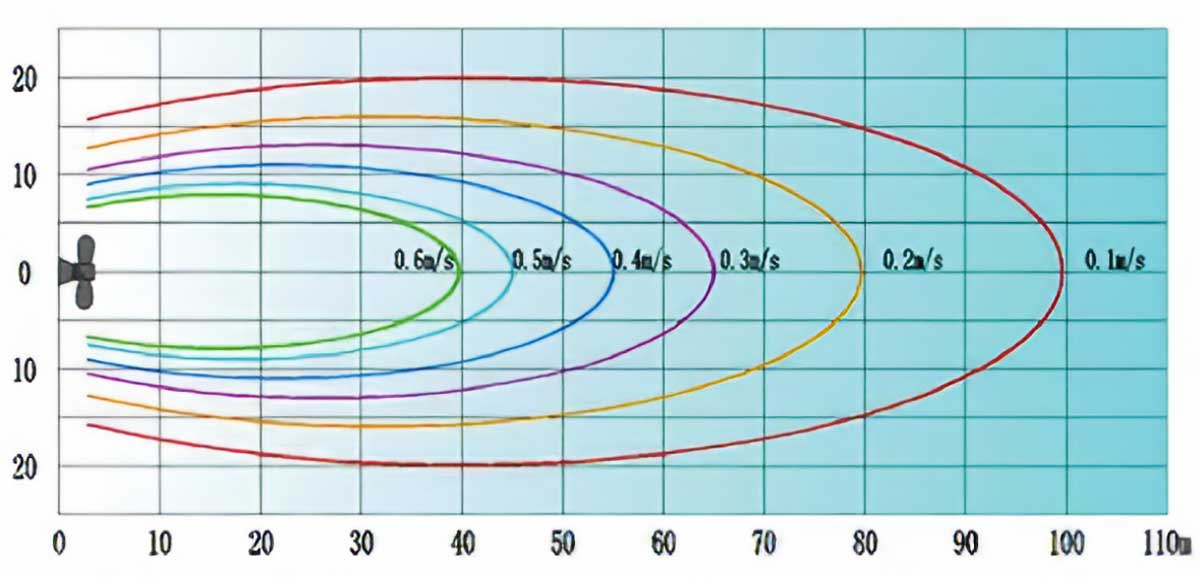

Mixing range speed of 0.Im/s (clear water)

Subersible Mixer Performance Parameters

| Model | Motor power (kw) | Electrode | Rated current (A) | RPM of vane or propellel (r/min) | Diameter of vane or propeller (mm) | Weight (kg) |

| QJB0.37/6 | 0.37 | 6 | 4 | 980 | 220 | 25 |

| QJB0.85/8 | 0.85 | 8 | 3.2 | 740 | 260 | 55 |

| QJB1.5/6 | 1.5 | 6 | 4 | 980 | 260 | 55 |

| QJB2.2/8 | 2.2 | 8 | 5.9 | 740 | 320 | 88 |

| QJB 4/6 | 4 | 6 | 10.3 | 960 | 320 | 88 |

| QJB1.5/8 | 1.5 | 8 | 5.2 | 740 | 400 | 74 |

| QJB2.5/8 | 2.5 | 8 | 7 | 740 | 400 | 74 |

| QJB 3/8 | 3 | 8 | 8.6 | 740 | 400 | 74 |

| QJB 4/6 | 4 | 6 | 10.3 | 980 | 400 | 74 |

JUNTAI Screw Press Advantages

1.Versatile: Suitable for various sludge types, including papermaking, printing and dyeing, and food processing sludge.

2.High Efficiency: Achieves dewatering rates of 70%–85%, significantly reducing material volume.

3.Compact Design: Space-saving structure, easy to install and fit in different locations.

4.Energy-Efficient: Low energy consumption compared to centrifugal dewatering machines, saving costs over long-term operation.

5.Smart Automation: Monitors and adjusts pressure, temperature, and flow automatically, reducing manual labor.

6.Space-Saving: Compact design minimizes land use, ideal for modern industrial needs.div容器product description

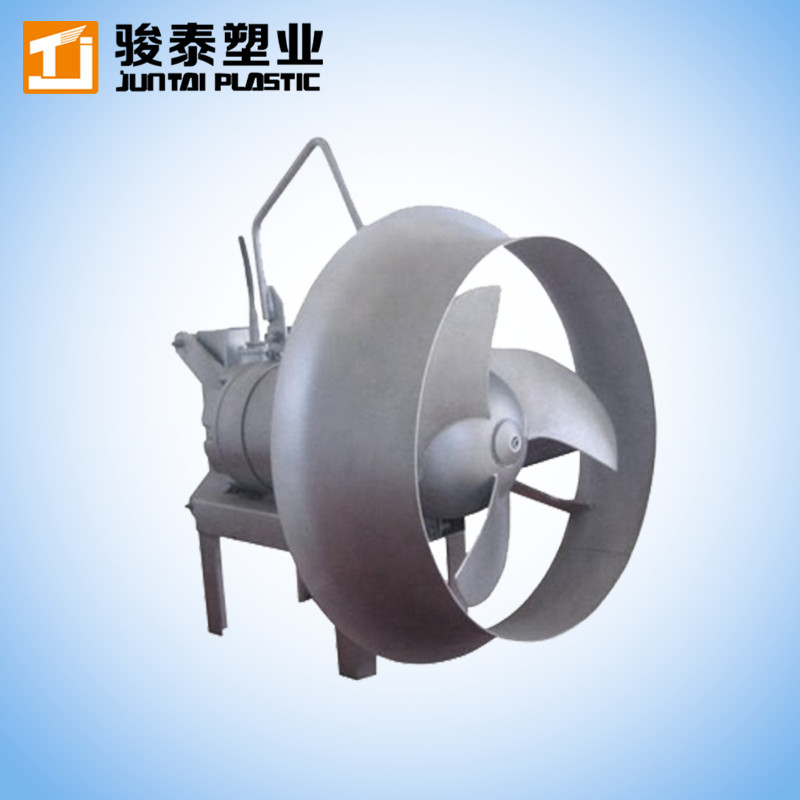

Lower Speed of Impeller speed is only 106 r/m, but Subersible Mixer most is 400 to 1000r/min, it is only 10 to 20% of them.Double-stage new reducer meets Bio carrier tank with special process requirements

Large diameter three-leaf stainless steel blades to meet Hydraulics and biocarrier process requirements

The propeller can achieve self-cleaning, the propeller is stainless steel material, Good design but also considering the function of automatic cleaning.

Equipped with the installation system developed by Juntai, it can be installed on the equipment from multiple angles.

Juntai Subersible Mixer Feature

1. Juntai submersible mixing compact structure, small volume, light weight, simple operation and maintenance, easy installation and maintenance, long service life.

2. The structure of the impeller has the optimum hydraulic design, work efficiency is high, after swept blade has self-cleaning function can prevent sundry winding, jam.

3. mixed with aeration system use can make a significant reduction in energy consumption, obviously improve the oxygen filling, effectively prevent the precipitation.

4. motor winding insulation class is F, protection grade IP68, chooses import disposable lubrication maintenance free high quality bearing, has the oil chamber leak detection and exclusive patent motor winding overheating protection and condensation prevention device, make the motor work more safety and reliable.

5. Two independent mechanical seal, mechanical seal friction pay for corrosion resistant material or carbide carbon, silicon, and fasteners are stainless steel material.

6. The unique design of cable seal ruled out the cable leakage hidden trouble.

7. Standard parts adopt why separation technology, can effectively prevent the corrosion.