+86 13600513715

+86 13600513715

01

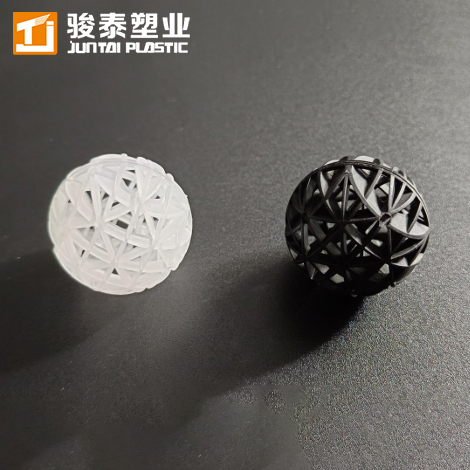

Long Service Life M BBR Biofilm Media in Wastewater Treatment

Product Parameters

| Item No. | Size |

| MBBR04 | 11mm*7mm |

| MBBR05 | 11mm*7mm |

| MBBR06 | 16mm*10mm |

| MBBR08 | 5mm*10mm |

| MBBR19 | 25mm*12mm |

| MBBR37 | 25mm*12mm |

| MBBR38 | 25mm*12mm |

| MBBR40 | 15mm*15mm |

| MBBR61 | 25mm*4mm |

| MBBR64 | 25mm*4mm |

| MBBR78 | 25mm*4mm |

| MBBR90 | 32mm*4mm |

Key Features of Our MBBR Media

1. Optimized Biofilm Growth & Efficiency

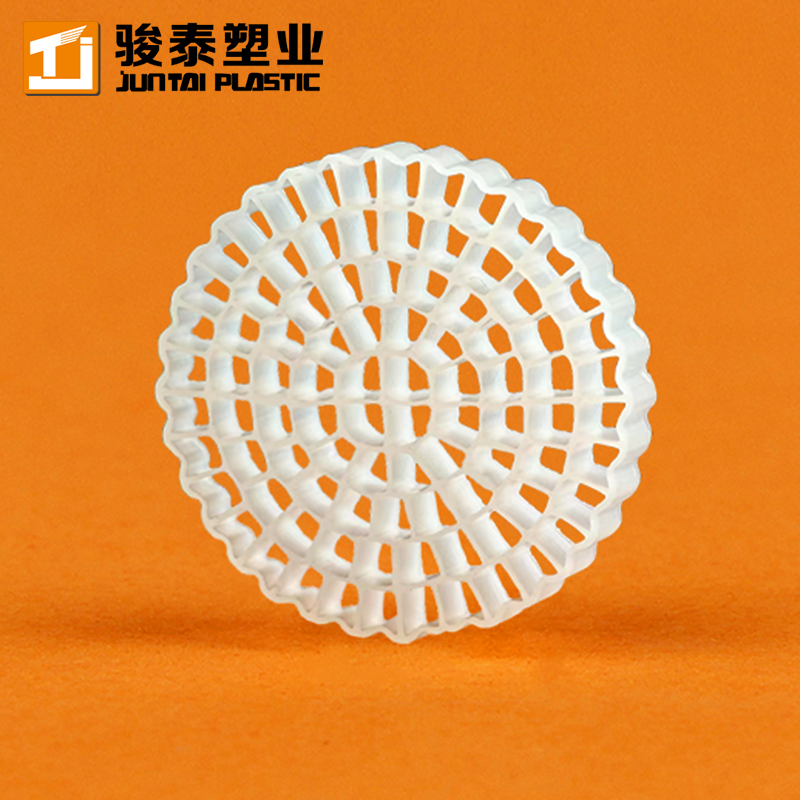

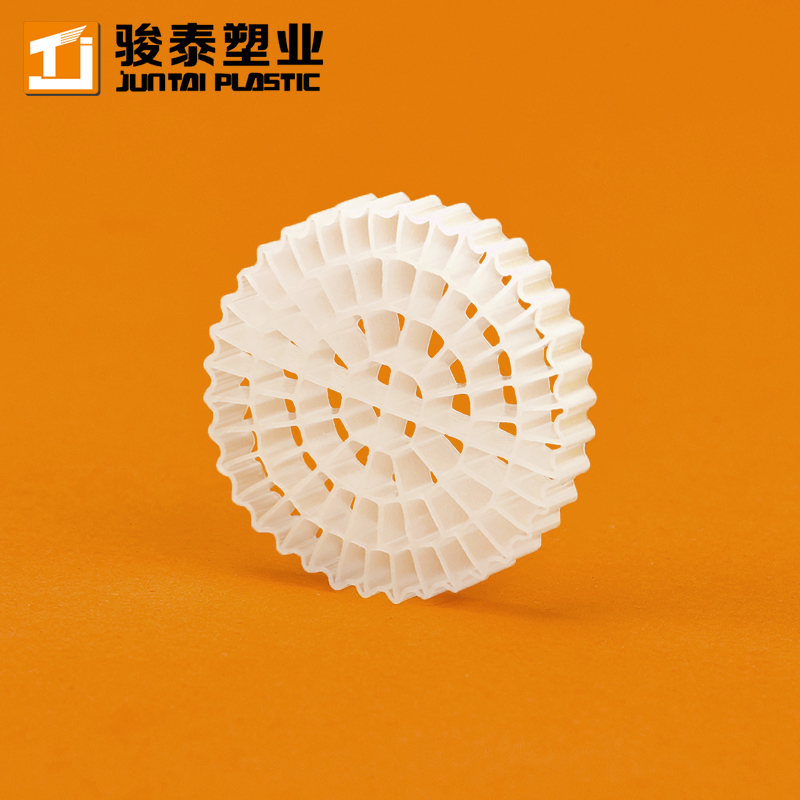

High Surface-to-Volume Ratio: Proprietary geometric designs (e.g., spiral grooves, micro-pores) provide 650-1,200 m²/m³ surface area for maximum biofilm colonization.

Anti-Clogging Structure: Dynamic self-cleaning design prevents sludge accumulation, ensuring stable performance in high-load wastewater (e.g., chemical, pharmaceutical, or food processing effluents).

2. Unrivaled Durability

Premium Material: Crafted from UV-stabilized HDPE/PP that resists corrosion, abrasion, and extreme pH (2–12), ideal for harsh environments like mining or marine wastewater.

15+ Year Lifespan: Tested to withstand continuous mechanical stress and temperature fluctuations (-30°C to 80°C).

3. Energy & Cost Savings

Enhanced Aeration Efficiency: Reduces energy consumption by 25-40% compared to traditional carriers, lowering operational costs for large-scale plants.

Low Maintenance Design: No frequent replacements, ensuring continuous operation with minimal downtime.

4. Eco-Friendly & Sustainable

100% Recyclable: Supports circular economy goals and aligns with LEED/ISO 14001 certifications.

Reduced Carbon Footprint: Lightweight design lowers transportation emissions and installation energy.

5. Customizable Solutions

Tailored Configurations: Adjustable media size (10–50 mm), density (0.95–0.98 g/cm³), and surface texture to match specific BOD/COD removal requirements.

Rapid Deployment: Compatible with retrofit systems or new installations, from compact rural units to mega municipal plants.

6. Globally Certified Quality

ISO 9001, CE, and SGS Certified: Guarantees consistent quality and compliance with international standards for EU, North American, and Asian markets.

7. Proven Global Success

Trusted by 500+ Clients: Deployed in 30+ countries for applications like oil refinery wastewater, aquaculture RAS systems, and smart city sewage networks.

24/7 Technical Support: Free consultation on biofilm activation, system optimization, and troubleshooting.

MBBR Media Product Advantages

As a leading Chinese manufacturer of MBBR (Moving Bed Biofilm Reactor) media, our high-performance plastic biofilm carriers are engineered to revolutionize wastewater treatment systems worldwide. Here’s why global clients choose our MBBR solutions:

1. Superior Biofilm Growth & Efficiency

High Surface Area Design: Optimized geometry (e.g., honeycomb, spiral, or porous structures) maximizes biofilm attachment, accelerating organic and nutrient removal.Our MBBR promoting the growth of microorganisms necessary for efficient biological treatment. This leads to improved removal of organic contaminants in wastewater.

Anti-Clogging Technology: Unique structural design ensures uninterrupted water flow, even in high-load industrial or municipal wastewater systems.

2. Unmatched Durability & Adaptability

Premium HDPE/PP Material: Corrosion-resistant, UV-stabilized, and chemically inert carriers withstand harsh environments (extreme pH, temperature fluctuations, or abrasive wastewater).

Made from high-quality, durable plastics, our MBBR media is resistant to corrosion, abrasion, and chemical attack, ensuring long-term performance in even the harshest environments.

Long Lifespan: Engineered for 15+ years of reliable performance, reducing replacement costs and downtime.

3. Cost-Effective & Sustainable Solutions

Energy-Saving Performance: Enhances aeration efficiency by 20-30%, slashing operational costs for large-scale treatment plants.

100% Recyclable: Eco-friendly HDPE/PP material supports circular economy goals and LEED-certified projects.Our MBBR media is made from environmentally friendly materials, contributing to sustainable wastewater treatment practices. By optimizing the use of space and energy, our products help to reduce the environmental footprint of treatment plants.

With reduced energy and maintenance costs, our MBBR media delivers a cost-effective solution for wastewater treatment, while ensuring high operational efficiency and compliance with environmental standards.

4. Versatile Applications

Multi-Scenario Ready: Ideal for industrial (chemical, pharmaceutical, food processing), municipal sewage, aquaculture, and decentralized rural wastewater systems.

Customizable Solutions: Tailor media size, density, and surface texture to meet specific BOD/COD removal targets.

Our MBBR media is available in various sizes and configurations, ensuring compatibility with different treatment plant designs. We can provide customized solutions to meet specific customer needs.

5. Global Compliance & Trust

Certified Quality: ISO 9001, CE, and SGS-certified production ensures consistent, reliable performance.

Proven Track Record: Trusted by 500+ clients across 80+ countries, from compact modular plants to mega-city wastewater projects.

Whether it’s municipal sewage treatment, industrial wastewater, or food processing effluent, our MBBR media has been proven to effectively treat a wide range of wastewater types, ensuring reliable

6.Easy to Install and Maintain

Our MBBR media is designed for easy installation and minimal maintenance, ensuring reduced downtime and operational costs for wastewater treatment plants.

7. Seamless Integration & Support

Plug-and-Play Design: Compatible with new or retrofit MBBR systems, minimizing installation complexity.

Technical Expertise: Free consultation for system optimization, biofilm startup, and troubleshooting.

MBBR Media Applications

1. Industrial Wastewater Treatment

Chemical & Pharmaceutical Plants: Efficiently degrades toxic organic compounds, solvents, and high-COD effluents.

Food & Beverage Processing: Handles high-fat, high-sugar, and protein-rich wastewater (e.g., dairy, breweries, slaughterhouses).

Oil Refineries & Petrochemicals: Removes hydrocarbons, phenols, and sulfides from complex industrial discharges.

Textile & Dyeing Facilities: Breaks down stubborn dyes, heavy metals, and alkaline wastewater.

2. Municipal & Urban Sewage Systems

City Sewage Treatment Plants: Cost-effective BOD/COD and nitrogen removal for high-flow urban networks.

Smart City Projects: Compact, modular systems for decentralized treatment in densely populated areas.

Hospital & Healthcare Wastewater: Safely treats antibiotic-resistant bacteria and pharmaceutical residues.

3. Agricultural & Aquaculture Applications

Livestock Farms: Manages high-ammonia wastewater from poultry, piggeries, and cattle farms.

Aquaculture & RAS Systems: Controls nitrate buildup in recirculating aquaculture systems (e.g., fish/shrimp farms).

Agricultural Runoff: Reduces pesticides and fertilizers in irrigation drainage water.

4. Harsh & Specialized Environments

Mining & Metallurgy: Treats acidic, heavy metal-laden wastewater (e.g., coal mines, smelters).

Marine & Offshore Platforms: Corrosion-resistant media for saline wastewater and ballast water treatment.

Cold Climate Regions: Temperature-stable performance in Arctic or alpine wastewater plants (-30°C).

5. Eco-Sensitive & Sustainable Projects

LEED-Certified Buildings: Supports green infrastructure for rainwater reuse and greywater recycling.

Eco-Tourism & Resorts: Low-energy, odor-free treatment for remote or environmentally protected areas.

Disaster Recovery: Rapid-deployment systems for emergency wastewater treatment post-floods or earthquakes.

6. Emerging & Niche Markets

Biogas Plants: Enhances anaerobic digestion by pre-treating high-solid organic waste.

Landfill Leachate: Tackles highly concentrated ammonia and refractory organics.

Microbrewery & Distillery Wastewater: Manages high-alcohol-content effluents sustainably.

7.Municipal Stormwater Treatment

Our MBBR media can also be used in systems designed to treat stormwater runoff, removing pollutants such as suspended solids, heavy metals, and organic materials before the water is discharged into the environment.

8.Bioreactor Systems and Retrofit Applications

Whether used in new bioreactor systems or retrofitting existing treatment plants, MBBR media is a flexible solution that integrates seamlessly into aerobic or anoxic treatment processes, improving system efficiency and capacity without the need for extensive redesign.

9.Decentralized and Small-Scale Wastewater Treatment

MBBR media is ideal for small-scale or decentralized wastewater treatment systems, such as those found in remote communities, resorts, or residential areas. It offers a compact, efficient, and low-maintenance solution for treating wastewater in locations with limited space or infrastructure.

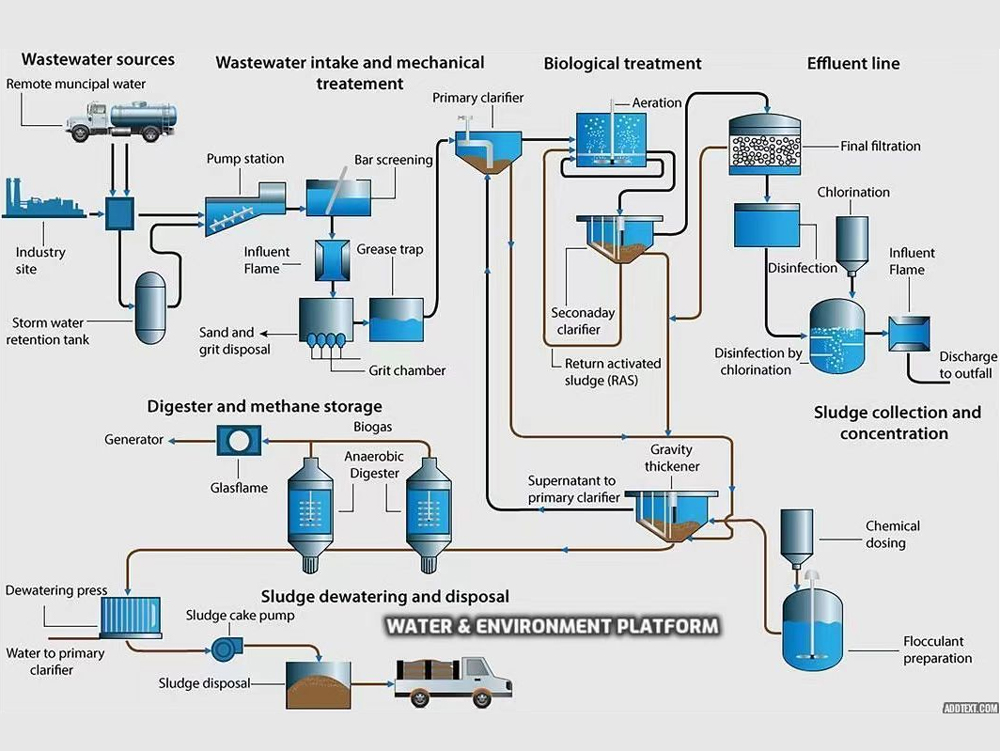

How MBBR Media Works?

The Moving Bed Biofilm Reactor (MBBR) technology is an advanced biological wastewater treatment method that uses plastic biofilm carriers to support the growth of microorganisms. This process efficiently removes organic matter, nitrogen, phosphorus, and other pollutants from wastewater in a compact, cost-effective, and energy-efficient manner.

Here’s a step-by-step explanation of how the MBBR process works:

1. Wastewater Inflow

Wastewater from municipal, industrial, or agricultural sources enters the treatment system. The influent typically contains organic materials, nutrients like nitrogen and phosphorus, and other pollutants that need to be removed.

2. Biofilm Carrier Immersion

In an MBBR system, plastic biofilm carriers (media) are suspended in a tank of wastewater. These carriers are lightweight, have a large surface area, and are designed to move freely within the tank. The media is kept in motion by aeration or mechanical mixing, which ensures constant contact with the wastewater.

3. Microbial Growth on Media

As wastewater flows over the biofilm carriers, microorganisms such as bacteria, protozoa, and algae colonize the surface of the media. These microbes form a biofilm—a thin layer of living organisms that feed on the organic pollutants in the wastewater, breaking them down through aerobic (oxygen-dependent) and anaerobic (non-oxygen dependent) processes.

4. Biological Treatment

The microbial biofilm on the carriers consumes the organic matter, nitrogen (as ammonia), phosphorus, and other pollutants in the wastewater. This biological degradation process helps reduce the biochemical oxygen demand (BOD), chemical oxygen demand (COD), total nitrogen (TN), and total phosphorus (TP), improving the quality of the effluent.

5. Oxygenation and Aeration

In aerobic MBBR systems, air is supplied through diffusers to maintain an optimal oxygen level in the tank. Oxygen is necessary for the microorganisms to break down organic matter. The aeration process also helps keep the biofilm carriers moving, ensuring uniform contact with the wastewater and preventing clumping of the media.

6. Settling and Clarification

Once the wastewater has been treated by the biofilm carriers, it flows to a settling tank or clarifier. Here, the remaining solids, including any excess biomass (sludge), settle to the bottom. The clarified effluent is then separated from the settled sludge.

7. Effluent Discharge or Reuse

The treated wastewater (effluent) is now of a much higher quality and can be safely discharged into the environment or reused for non-potable applications, such as irrigation, cooling, or industrial processes. The effluent typically meets or exceeds local environmental discharge standards.

8. Sludge Removal and System Maintenance

Periodically, excess biomass (sludge) is removed from the system. This is typically done through a controlled waste sludge process. The MBBR system requires minimal maintenance, as the plastic carriers have a long lifespan and are resistant to fouling.

Why Choose JunTai as Your MBBR Media Partner?

1. Unmatched Manufacturing Expertise

✅ 20+ Years of Specialization: As a leading Chinese factory dedicated to MBBR media R&D and production, we combine cutting-edge technology with deep industry know-how.

✅ ISO 9001 & CE Certified: Rigorous quality control ensures every batch meets global standards for durability and performance.

2. Superior Product Performance

🔥 High-Efficiency Biofilm Carriers:

1,000+ m²/m³ Surface Area: Patented geometric designs (spiral grooves, micro-pores) maximize biofilm attachment for rapid BOD/COD removal.

Anti-Clogging & Self-Cleaning: Ensures stable operation in high-load wastewater (chemical, food, or municipal sewage).

🏋️ Built to Last:

UV-Stabilized HDPE/PP Material: Resists corrosion, extreme pH (2–12), and temperatures (-30°C to 80°C), ideal for harsh environments like mining or marine applications.

15+ Year Lifespan: Slashes long-term replacement costs.

3. Cost-Effective Solutions

💰 Factory-Direct Pricing: Eliminate middlemen – enjoy 30% lower costs versus European or American suppliers.

⚡ Energy Savings: Our media reduces aeration energy by 25–40%, cutting operational expenses for large-scale plants.

4. Customization & Flexibility

🎯 Tailored to Your Needs:

Adjust media size (10–50 mm), density (0.94–0.98 g/cm³), and surface texture for specific contaminants (ammonia, phosphates, hydrocarbons).

Custom branding and packaging available.

🌍 Global Adaptability: Products comply with EU, US EPA, and China GB standards, ensuring seamless integration into your regional system.

5. Proven Global Success

🌐 Trusted by 500+ Clients: From oil refineries in the Middle East to smart city projects in Europe and aquaculture farms in Southeast Asia.

📈 Scalable Solutions: Serve projects of all sizes – from rural decentralized units (<1,000 PE) to mega municipal plants (>1M PE).

6. Hassle-Free Service & Support

🚚 Fast Global Shipping: Bulk orders delivered within 2–3 weeks – urgent requests prioritized.

🆓 Free Samples & Testing: Validate performance with no-obligation trials.

🛠️ 24/7 Technical Support: Multilingual experts assist with system design, biofilm activation, and troubleshooting.

7. Sustainability Commitment

♻️ 100% Recyclable Materials: Align with LEED, ISO 14001, and corporate ESG goals.

🌱 Low Carbon Footprint: Energy-efficient production and lightweight media reduce emissions across the lifecycle.

Key Factors to Consider When Choosing MBBR Media

As a leading MBBR media manufacturer, Hangzhou JunTai (JTC) provides globally trusted solutions for wastewater treatment. Below are critical factors clients should evaluate to select the optimal MBBR system for their needs:

1. Carrier Material and Design

Material Durability: Prioritize UV-stabilized HDPE or PP carriers resistant to corrosion, extreme pH (2–12), and temperature fluctuations (-30°C to 80°C). These materials ensure longevity in harsh environments like mining or marine wastewater.

Surface Area & Geometry: Opt for high-specific-surface-area carriers (e.g., 800–1,200 m²/m³) with spiral grooves or micro-pores to maximize biofilm attachment and pollutant degradation efficiency.

Anti-Clogging Design: Ensure carriers have self-cleaning structures to prevent sludge buildup, critical for high-load industrial or municipal systems.

2. Application-Specific Requirements

Wastewater Type:

Industrial: For chemical, pharmaceutical, or food processing effluents, select carriers tailored to high COD/BOD removal and resistance to toxic substances.

Municipal: Use media optimized for nitrogen/phosphorus removal and low-temperature resilience (e.g., 4°C–10°C in northern regions).

Aquaculture/Aggressive Environments: Choose saltwater-resistant carriers for marine applications or anti-abrasion designs for mining wastewater.

Treatment Goals:

Nutrient Removal: Hybrid MBBR systems enhance simultaneous nitrification-denitrification (SND) and phosphorus uptake1314.

Capacity Expansion: For plant upgrades, select media compatible with retrofitting existing tanks without increasing footprint14.

3. System Design and Compatibility

Aeration Efficiency: Match carriers to energy-saving aeration systems (e.g., micro-bubble diffusers) to reduce energy consumption by 20–30% compared to fixed-bed reactors.

Hydraulic Retention Time (HRT): Adjust HRT based on flow rate and pollutant load. Short HRTs require high-surface-area carriers to maintain efficiency.

Interception Systems: Ensure proper sieve design (e.g., stainless steel screens) to prevent media loss while maintaining flow rates.

4. Operational Conditions

Temperature Adaptability: For cold climates (e.g., <10°C), use carriers that support biofilm activity under low temperatures, leveraging MBBR’s superior cold resistance over activated sludge15.

Dissolved Oxygen (DO) Control: Maintain DO levels (2–4 mg/L) to balance aerobic and anoxic zones for optimal nitrification/denitrification.

pH Stability: Monitor and adjust pH (6.5–8.5) to avoid microbial inhibition.

5. Cost and Sustainability

Lifecycle Costs: Compare initial investment vs. long-term savings. MBBR media with 15+ year lifespans reduce replacement costs, while low-energy aeration cuts operational expenses.

Sludge Reduction: MBBR generates 40–50% less sludge than activated sludge systems, lowering disposal costs28.

Recyclability: Choose 100% recyclable HDPE/PP carriers to align with LEED or ISO 14001 sustainability goals.

6. Supplier Credibility

Certifications: Verify ISO 9001, CE, and SGS compliance for quality assurance.

Customization: Partner with suppliers offering tailored media (size, density, texture) and OEM/ODM services.

Proven Track Record: Prioritize manufacturers with global deployments (e.g., 500+ projects in 30+ countries) and technical support for biofilm activation and troubleshooting.

Your Trusted Partner in Wastewater Excellence

At JunTai, we empower industries and communities worldwide to achieve sustainable, efficient wastewater treatment. Whether you’re an engineer designing a municipal plant, a manager optimizing industrial processes, or a consultant tackling niche environmental challenges, our MBBR media solutions are tailored to your success.

Who We Serve

🏭 Industrial Leaders: Chemical, pharmaceutical, food processing, oil & gas, and textile industries.

🏙️ Municipal Authorities: City sewage plants, smart city projects, and decentralized rural systems.

🌾 Agricultural Innovators: Livestock farms, aquaculture (RAS), and agricultural runoff treatment.

🌍 Global Sustainability Champions: LEED-certified projects, eco-tourism resorts, and disaster recovery initiatives.

What You Gain with Juntai

✅ Latest Technical Resources:

Free Product Manuals: Download our 2024 MBBR Media Brochure for specs, case studies, and compliance data.

Compliance Guides: Access region-specific regulatory checklists (EU, US EPA, Asia).

✅ Risk-Free Testing:

Free Samples: Test our media in your system – no upfront costs, no obligations.

Performance Reports: Validate efficiency with lab-tested BOD/COD removal data.

✅ Tailored Solutions:

Custom Media Design: Adjust size, density, and texture for unique contaminants (ammonia, heavy metals, etc.).

OEM/ODM Services: Co-branded packaging and bulk order discounts.

✅ Expert Support:

24/7 Technical Consultations: From biofilm activation to system retrofitting.

Fast Global Logistics: Bulk orders shipped in 2–3 weeks, backed by real-time tracking.