+86 13600513715

+86 13600513715

01

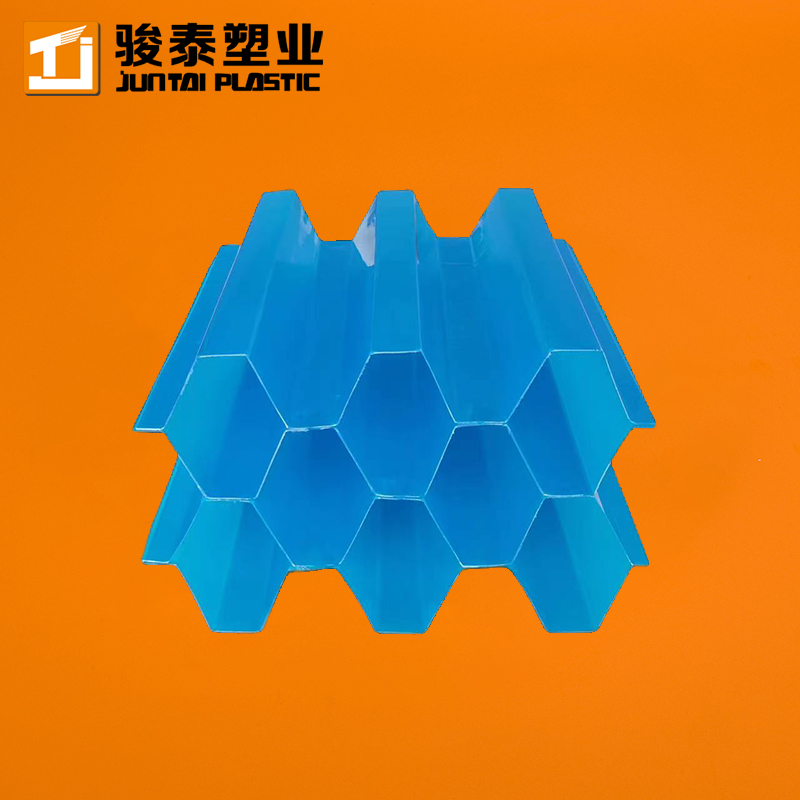

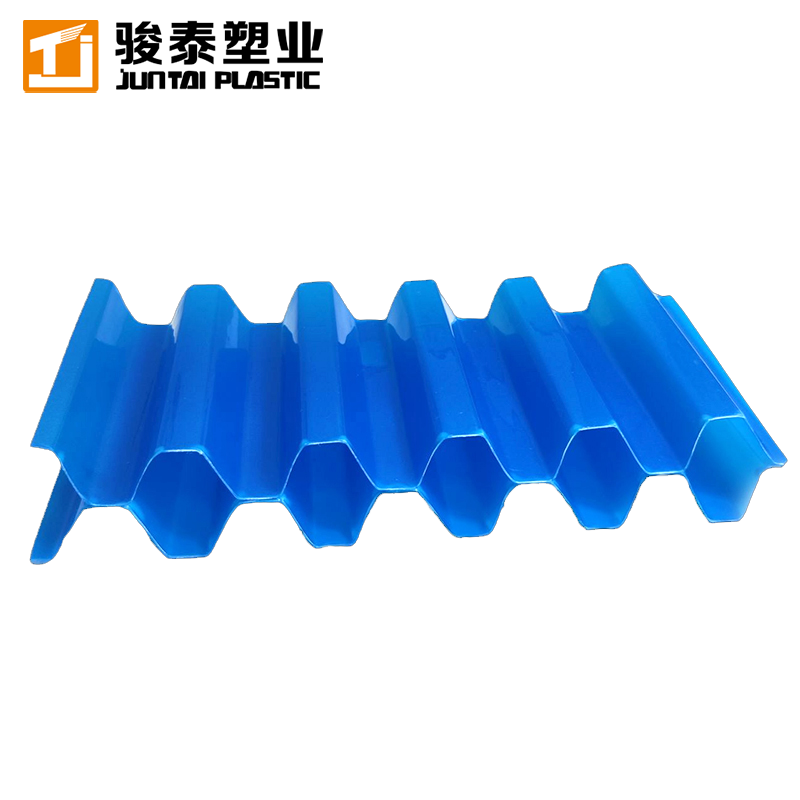

UV-Resistant PP/PVC Honeycomb Lamella Tube Settler Clarifier Suppliers

How Tube Settlers Work

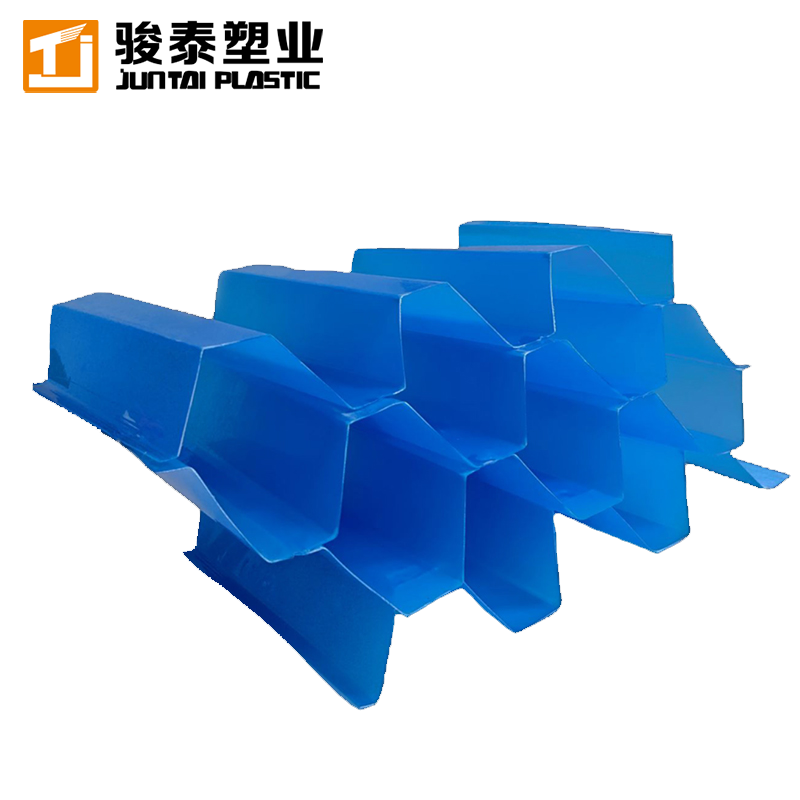

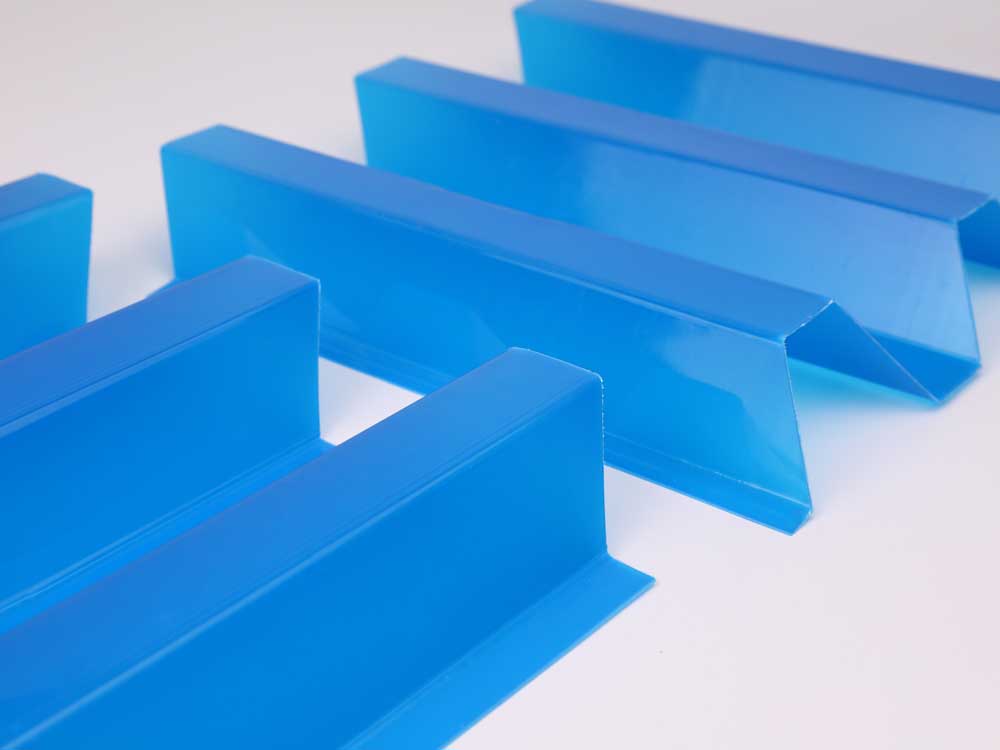

Water flows through the inclined honeycomb channels, where the flow is guided, and the velocity is reduced. This allows suspended solids in the water to settle to the bottom of the tubes due to gravity. The 60-degree angle accelerates the settling process as solid particles in the water are more easily driven downward by gravity at this angle.

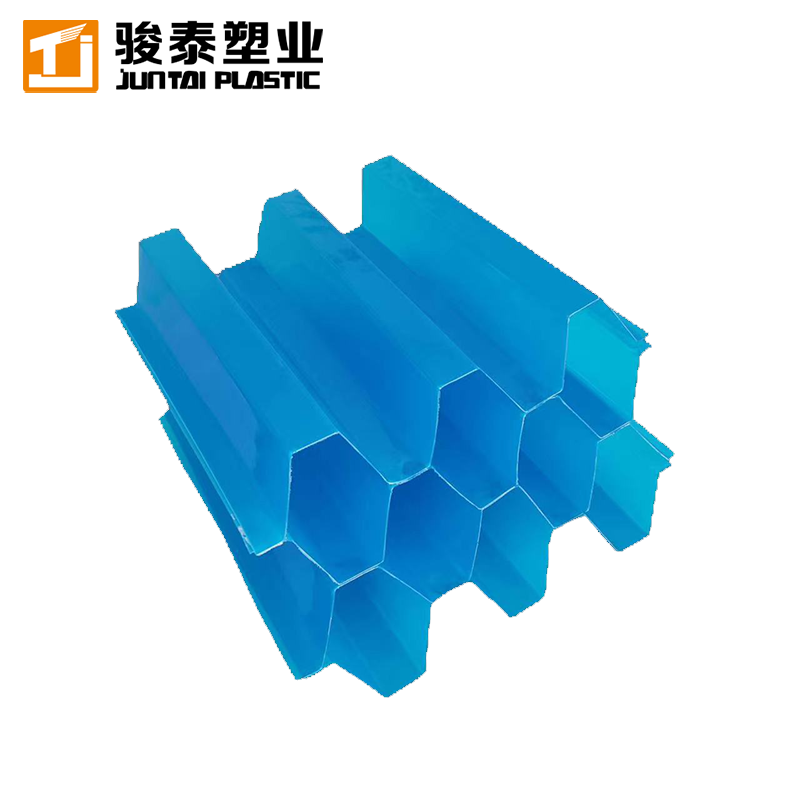

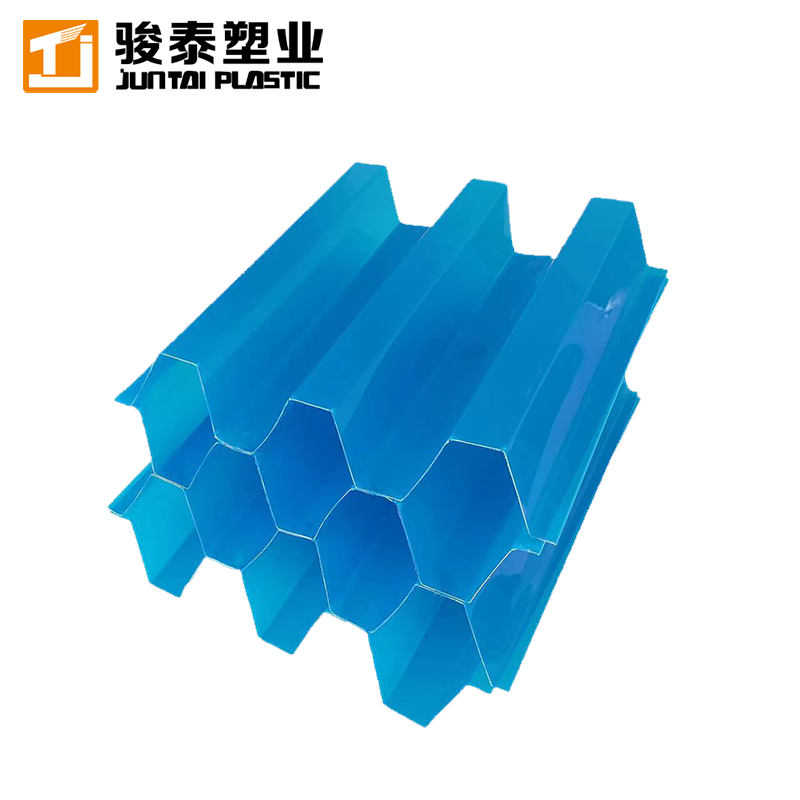

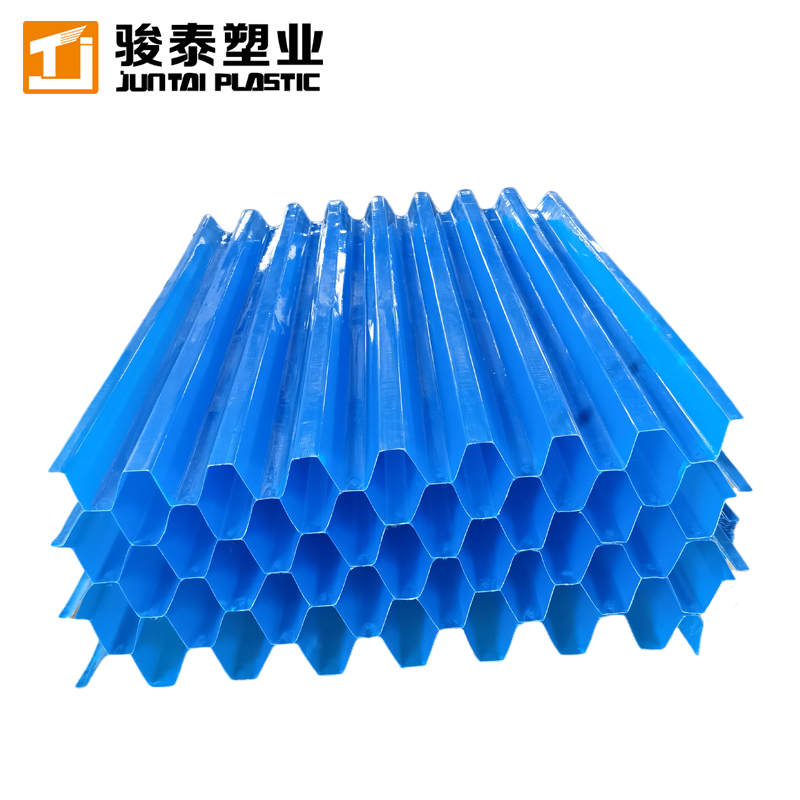

The honeycomb structure of tube settlers significantly increases the contact area between the water and the settling surface. This not only improves the settling efficiency of solid matter in the water but also effectively optimizes the use of space in the clarifier. By increasing the surface area, more suspended solids can settle in a shorter amount of time, reducing the required volume of the settling tank.

As the water flows through the honeycomb structure and passes through the settling zone, the majority of the solid particles in the water have already settled to the bottom of the tank. The clarified water is then discharged through pipes at the top, completing the settling process.

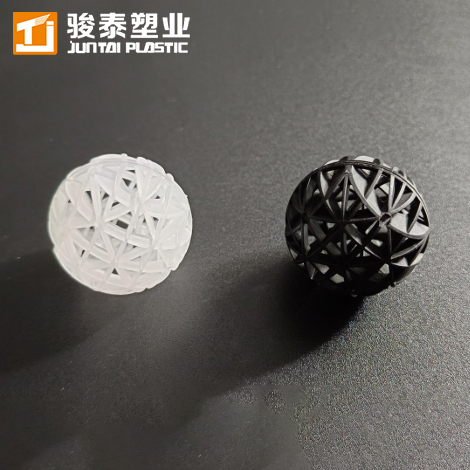

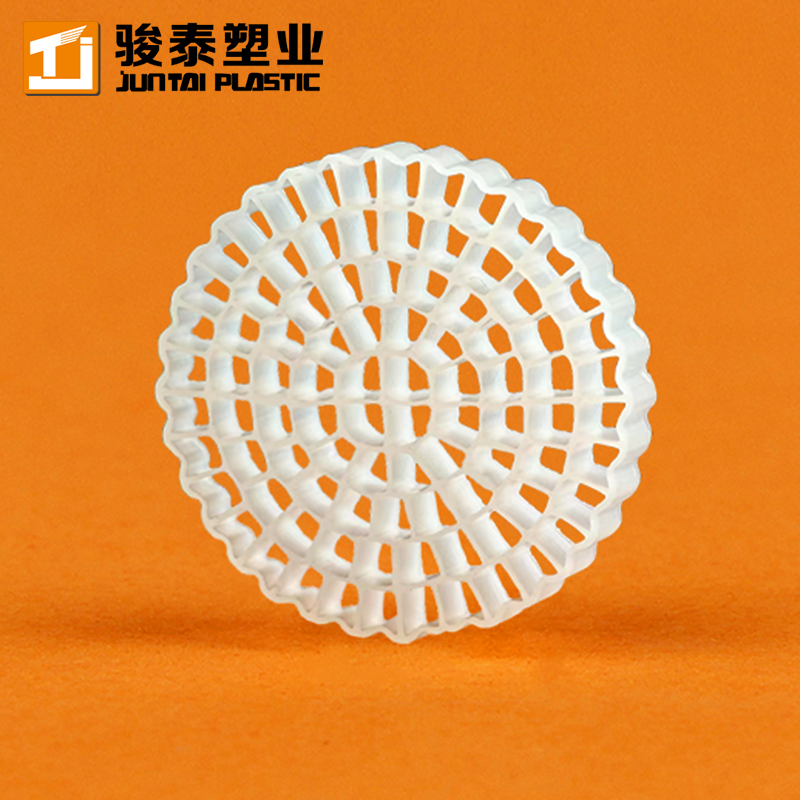

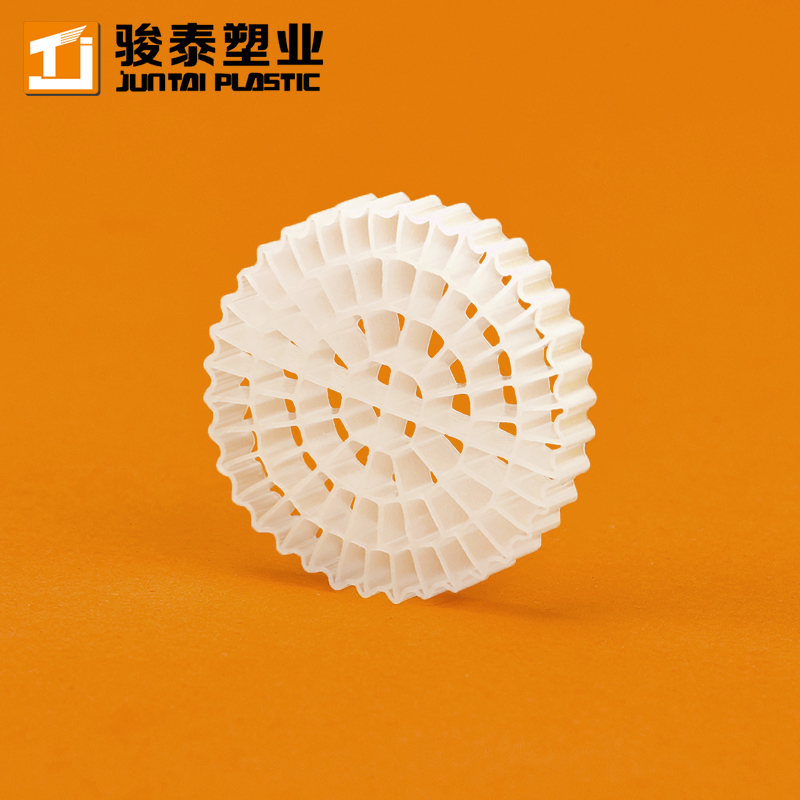

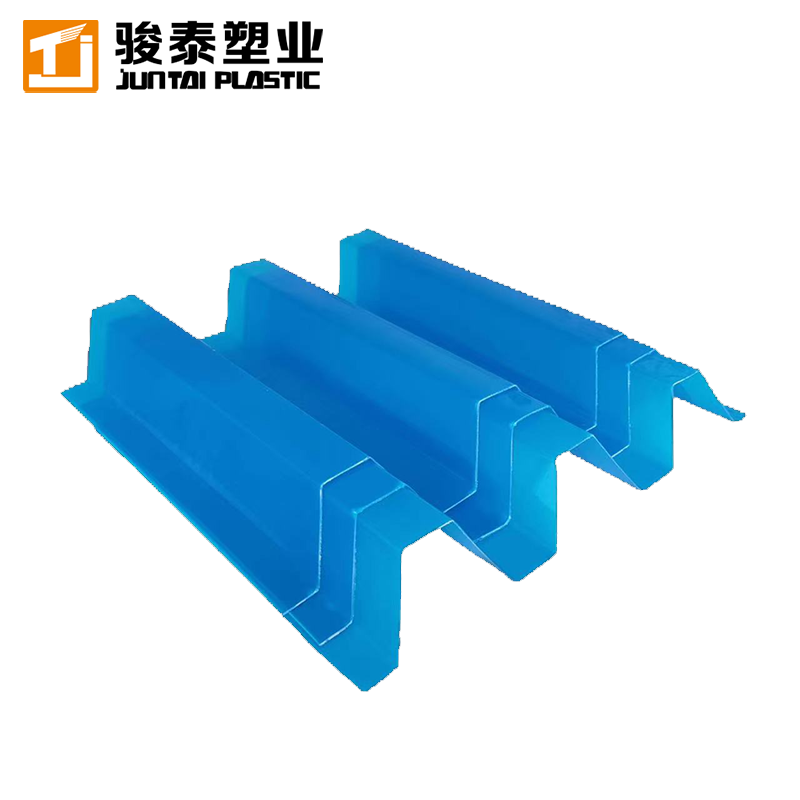

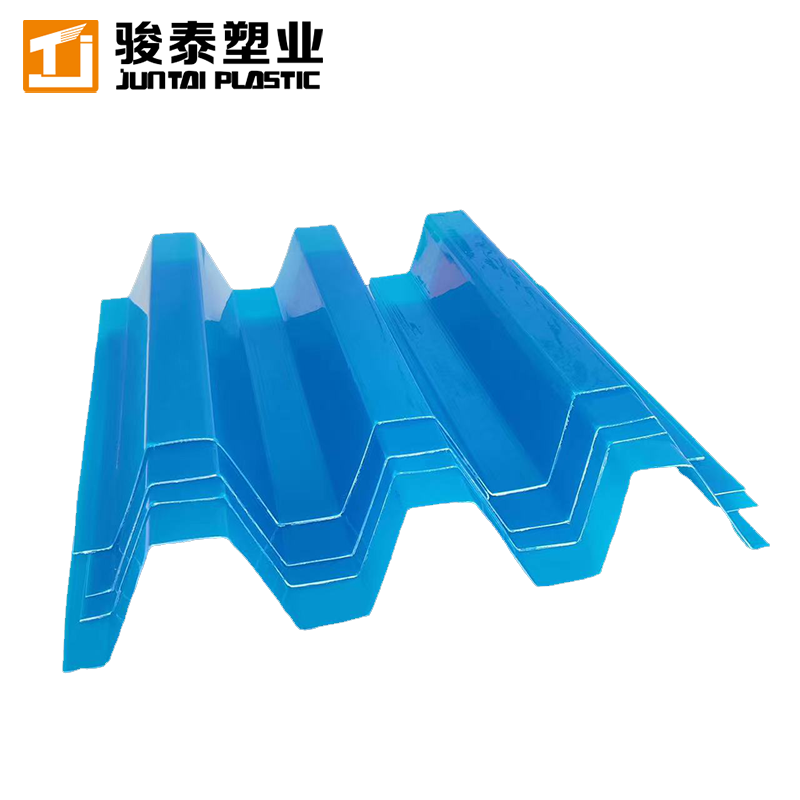

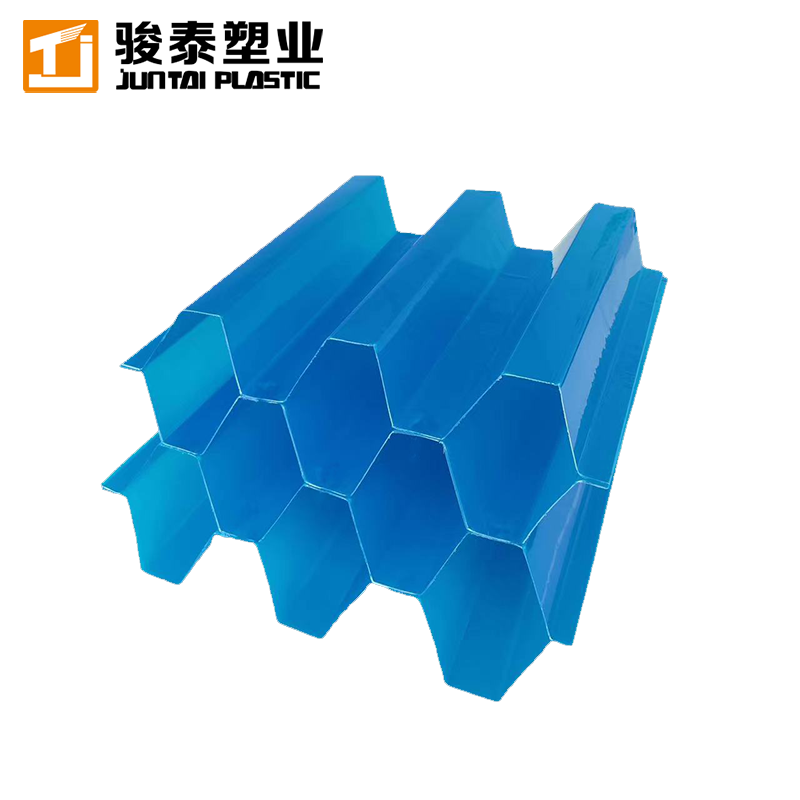

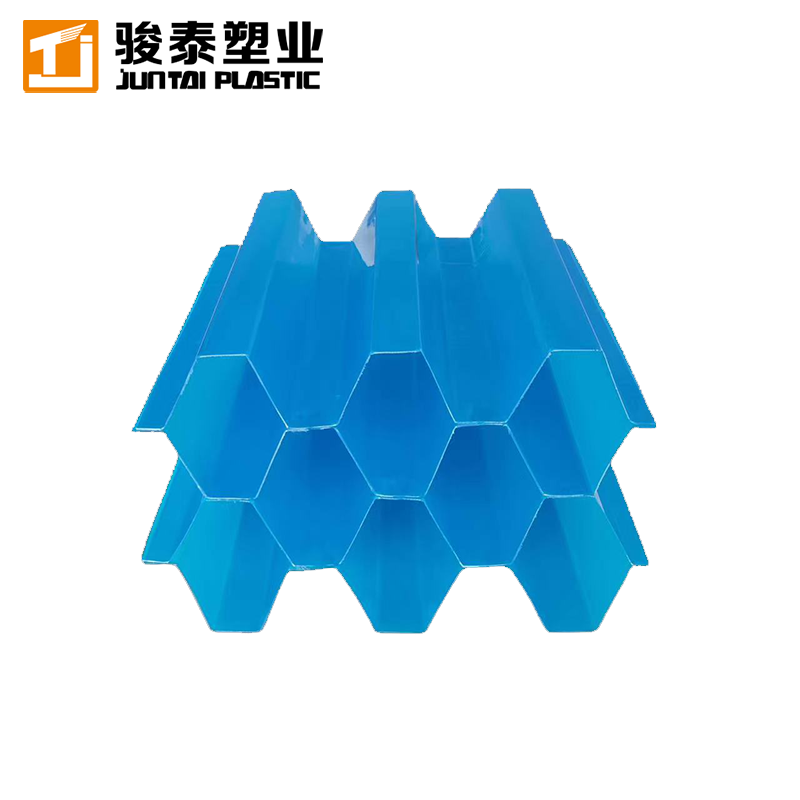

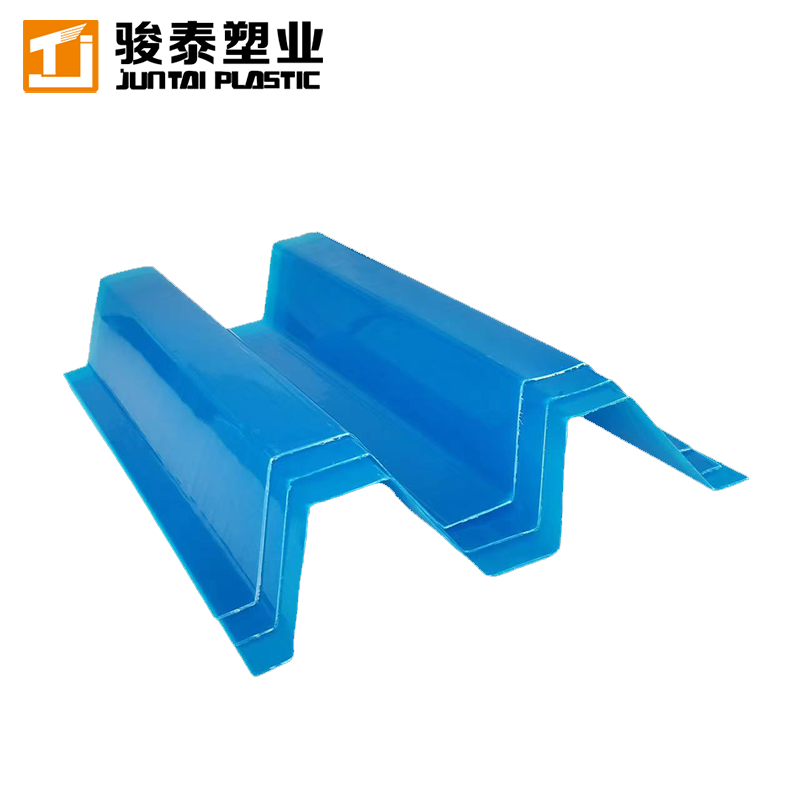

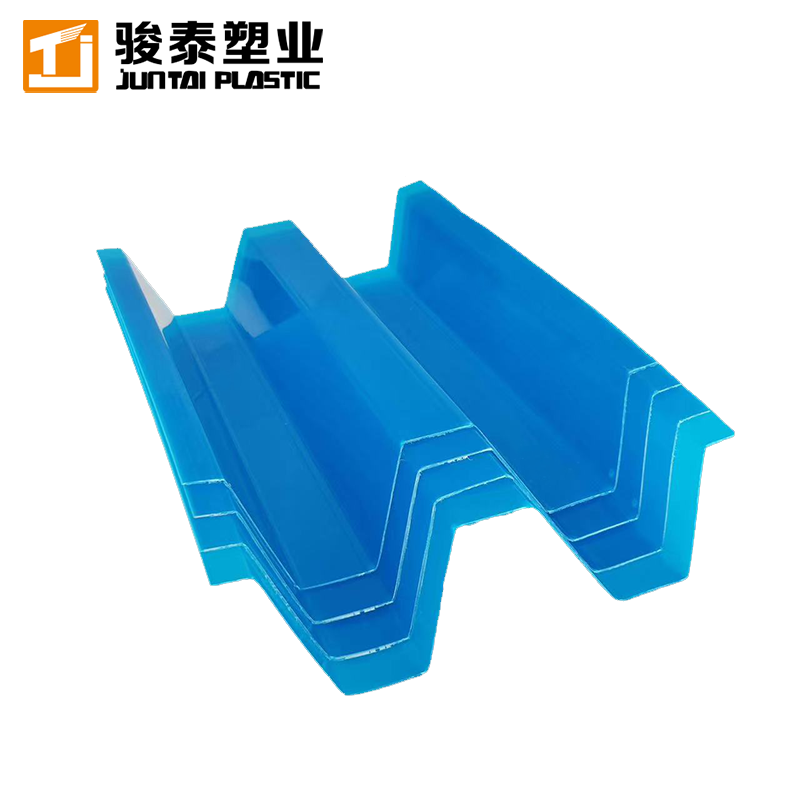

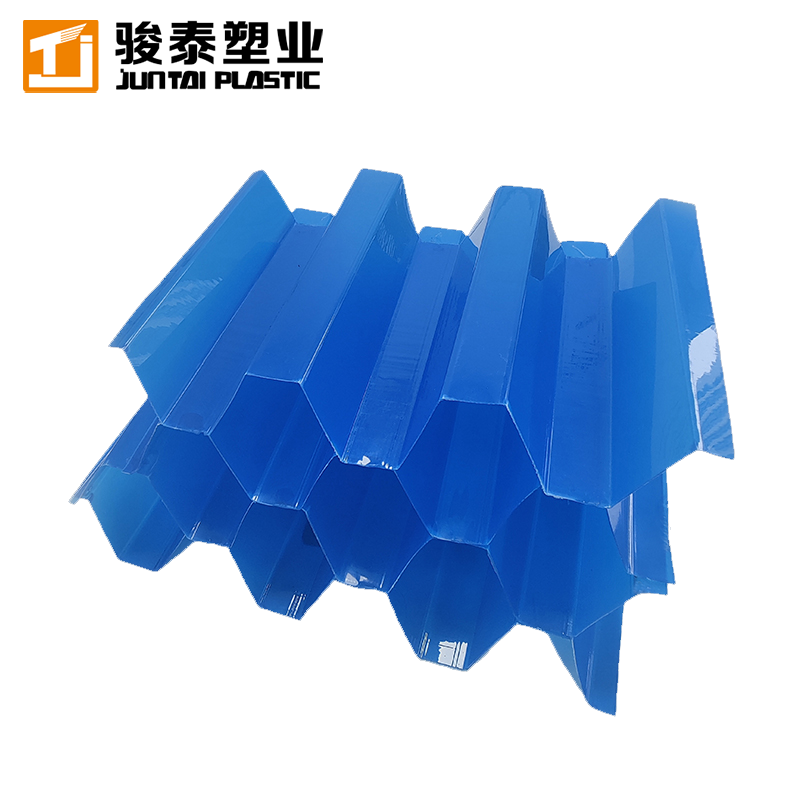

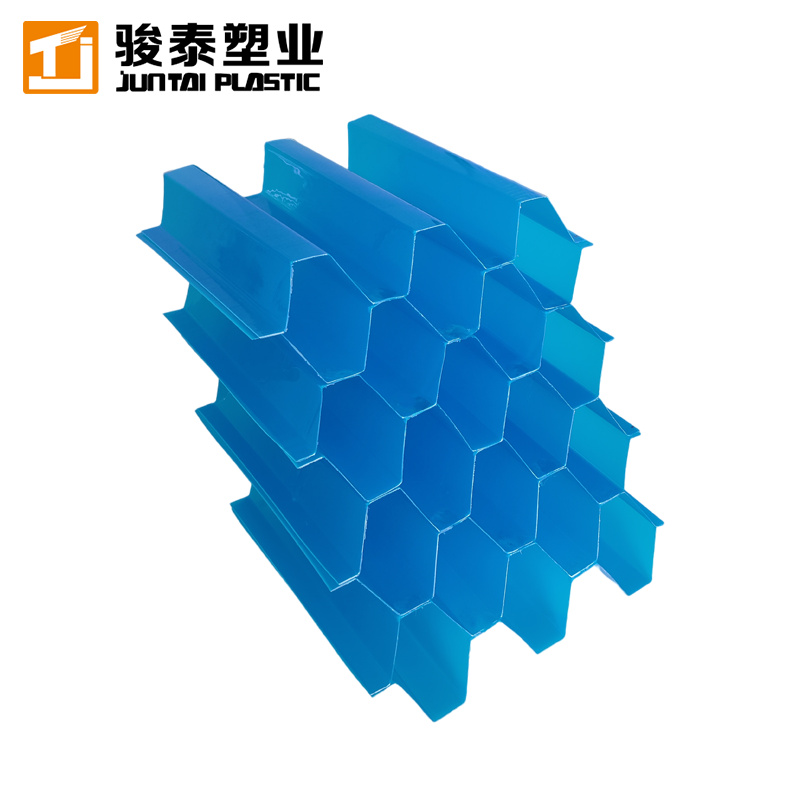

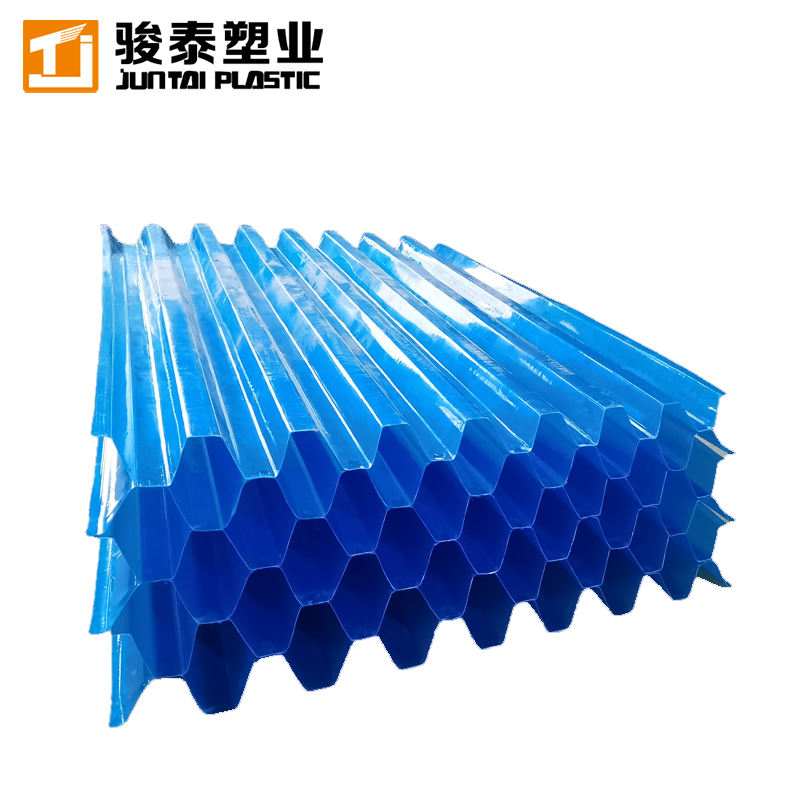

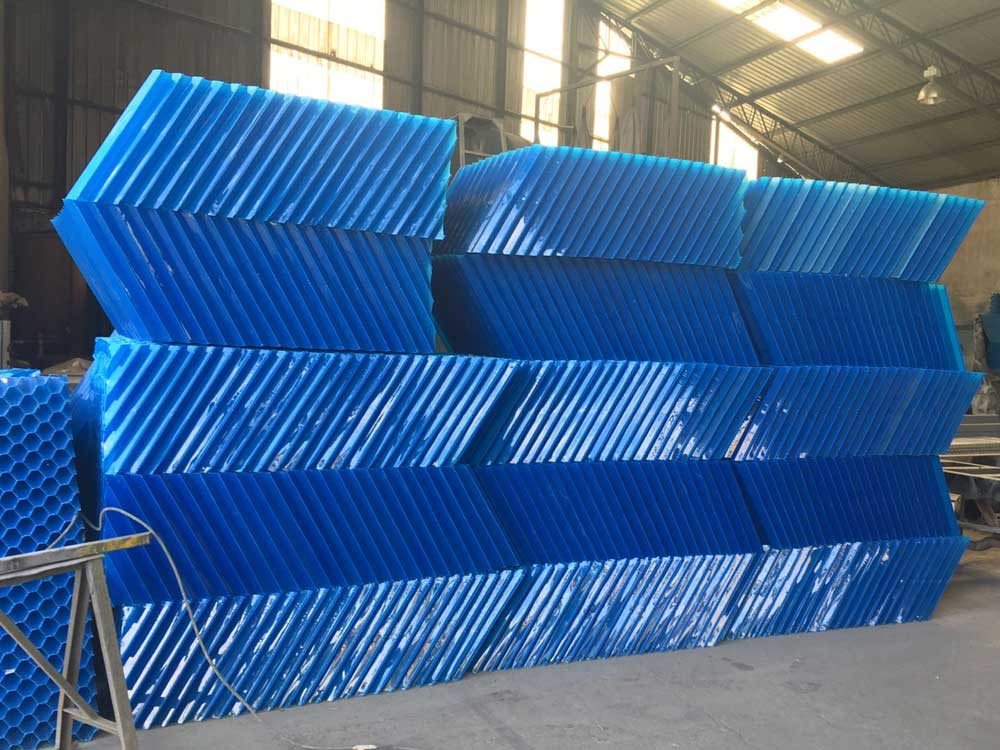

Product Display

product accessories

Benefits of Juntai Tube Settlers

Bionic Hexagonal Structure: Mimicking the mechanics of a honeycomb, this design improves impact resistance by 22%, maximizes the settling surface area, and minimizes the footprint. It provides higher sedimentation capacity in a more compact space.

60° Optimal Angle Design: Verified through fluid simulation, this precise design balances settling speed and sludge sliding efficiency, improving performance by 15% compared to traditional tube settlers.

UV-Resistant Patented Technology: The use of UV-resistant masterbatch significantly extends the lifespan of the tube settlers.

Significantly Reduced Tank Size

Large channel opening size reduces the risk of clogging

Easy Installation & Maintenance: Simple to operate and easy to install. Contact us for installation guides for tube settlers.

Suitable for Different Types of Wastewater:

a.Drinking Water: Made from original Polypropylene (PP), certified by SGS, CE, and FDA standards.

b.Industrial Wastewater: Available in Polyvinyl Chloride (PVC), resistant to corrosive media like hydrofluoric acid.

Specifications

| Product | Picture | Diameter | Color | Material | Installation angle(°) | Thickness (mm) | PCS/CBM |

| TL35PP/PVC |  |

35 | Blue/White | PP/PVC with UV resistance | 60 | 0.4-1.5 | 40 |

| TL50PP/PVC |  |

50 | Blue/White | PP/PVC with UV resistance | 60 | 0.4-1.5 | 30 |

| TL80PP/PVC |  |

80 | Blue/White | PP/PVC with UV resistance | 60 | 0.4-1.5 | 20 |

applications

TSS removal and particle separation

Upgrade of existing sedimentation tanks

Tertiary or secondary clarification for municipal WWTP

Drinking water plant clarifiers

Industrial wastewater treatment

Compact Retrofit Program

Process water applications

Examples of process water applications: Desalination, food and beverages, heavy metal, pulp and paper, petrochemical, process water, Pharmaceutical, Chemical, Steel, Machinery, Mining and more