+86 13600513715

+86 13600513715

01

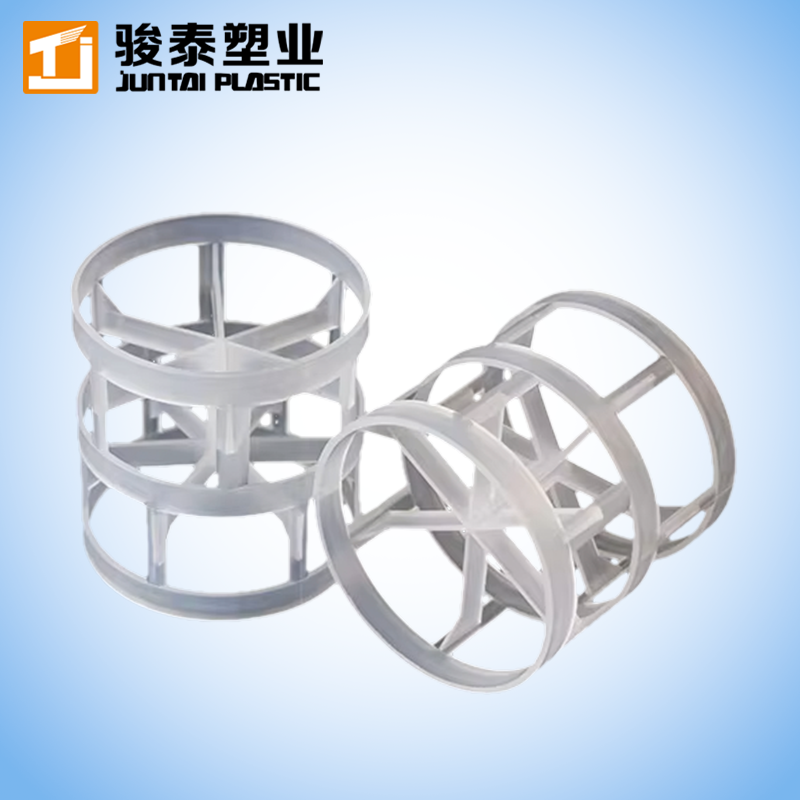

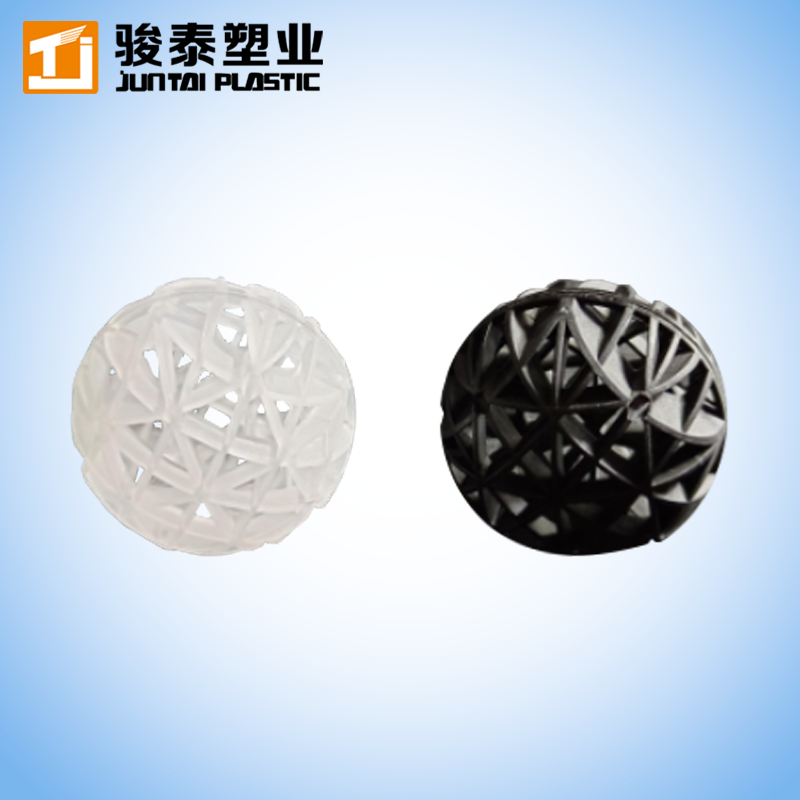

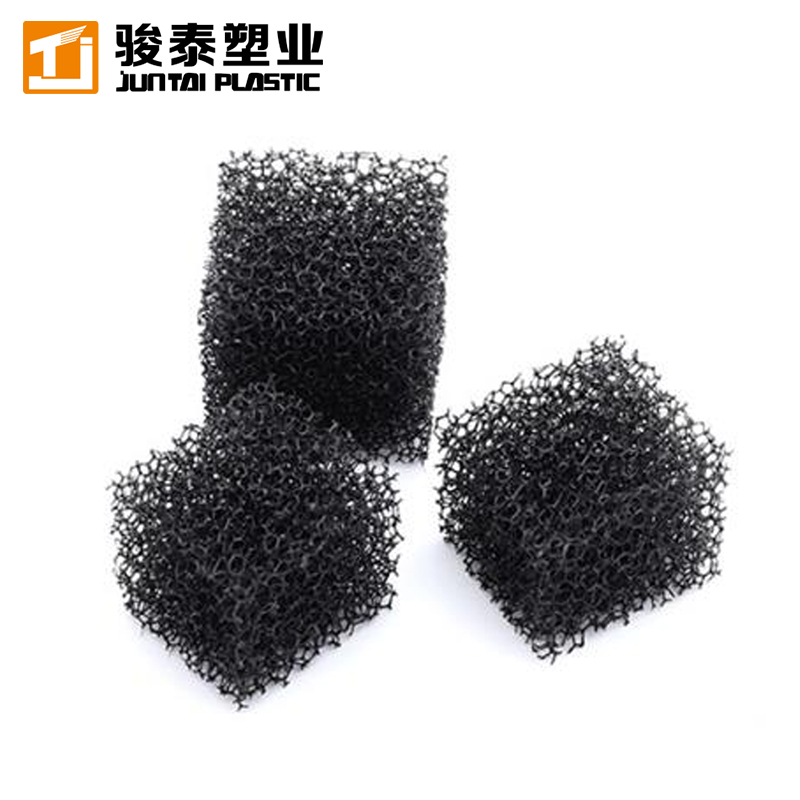

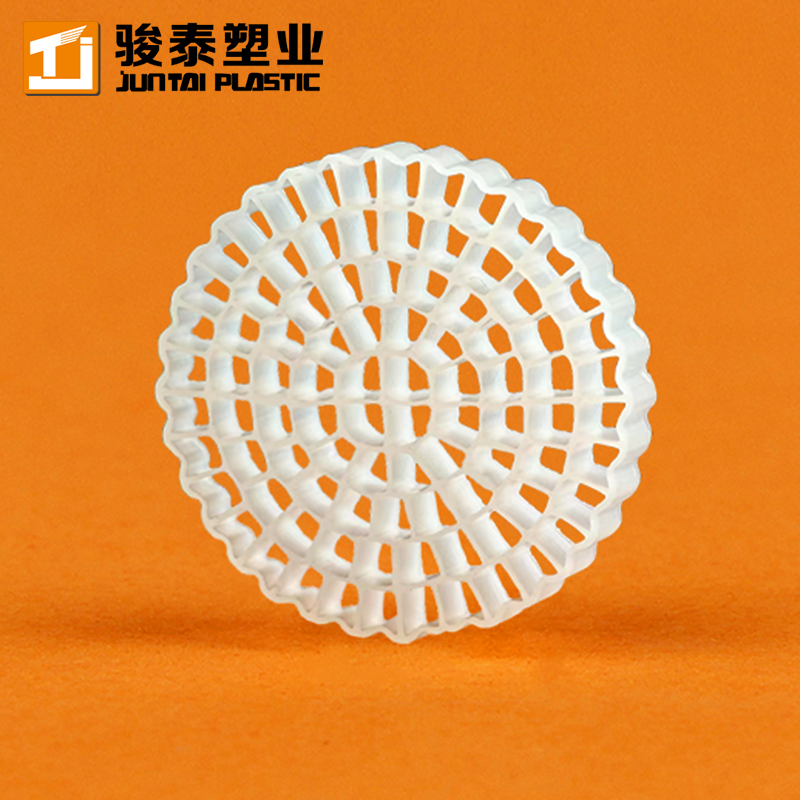

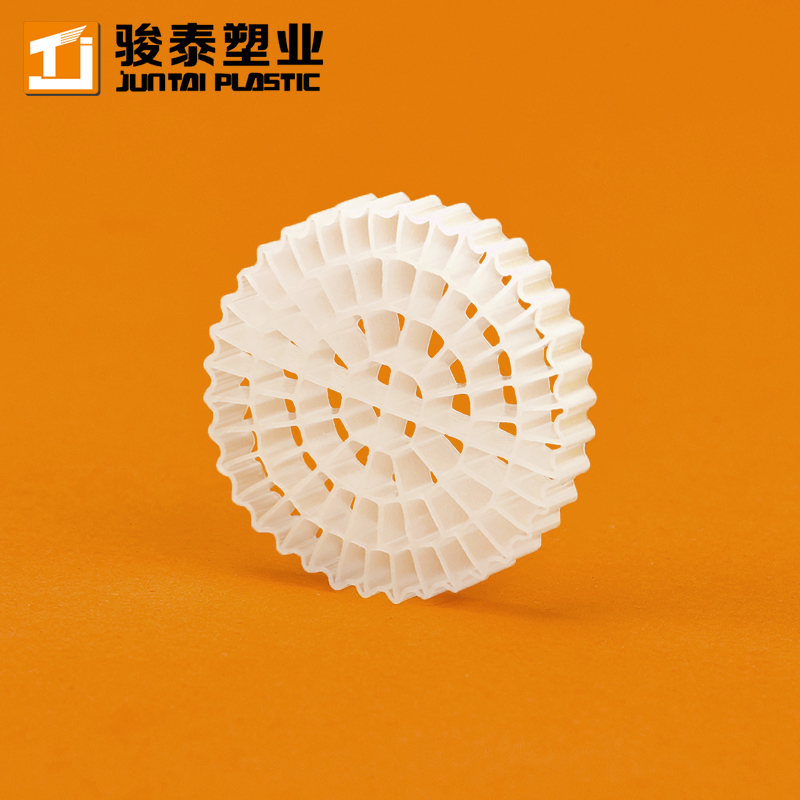

Eco-Friendly Bio Block Filter Media for Aquaculture

Key Features of Bio Block

1.Ultra-High Surface Area

3D Matrix maximizes microbial colonization, boosting treatment capacity by 50% compared to conventional media.

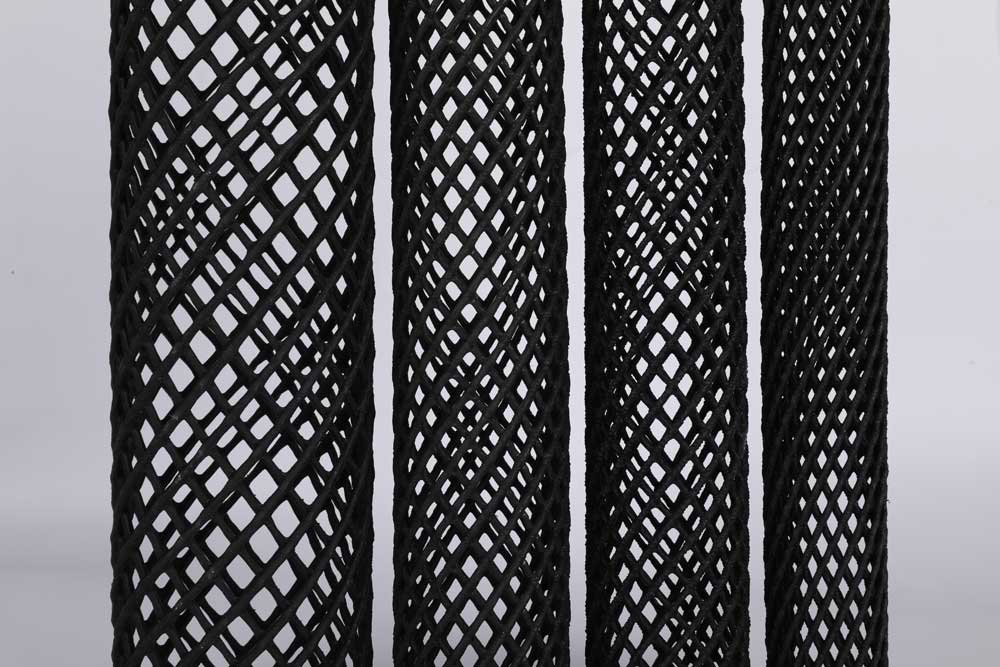

2.Anti-Clogging Open Structure

Dynamic grid design prevents sludge buildup, ensuring stable performance in MBBR, IFAS, and deaeration towers.

3.Corrosion & UV Resistance

Made from virgin HDPE/PP with UV stabilizers, ideal for outdoor lagoons, acidic wastewater, and saltwater aquaculture.

4.Energy-Efficient Design

Low-density floating media reduces aeration energy by 25-30%, lowering operational costs for large-scale plants.

5.Modular & Scalable

Interlocking units allow flexible stacking to fit any tank size, from compact fish farms to industrial bioreactors.

6.Certified Safety

NSF/FDA-compliant materials safe for potable water and sensitive species (e.g., shrimp, salmon).

7.Extreme Temperature Tolerance

Operates reliably in -40°C to 120°C, suitable for biogas plants and cold-climate wastewater facilities.

8.Proven Deaeration Efficiency

Removes 95%+ dissolved gases (CO2, H2S) in RAS systems, enhancing fish health and growth rates.

9.Global Compliance

Meets EU REACH, RoHS, and ISO 9001 standards for eco-friendly manufacturing and export.

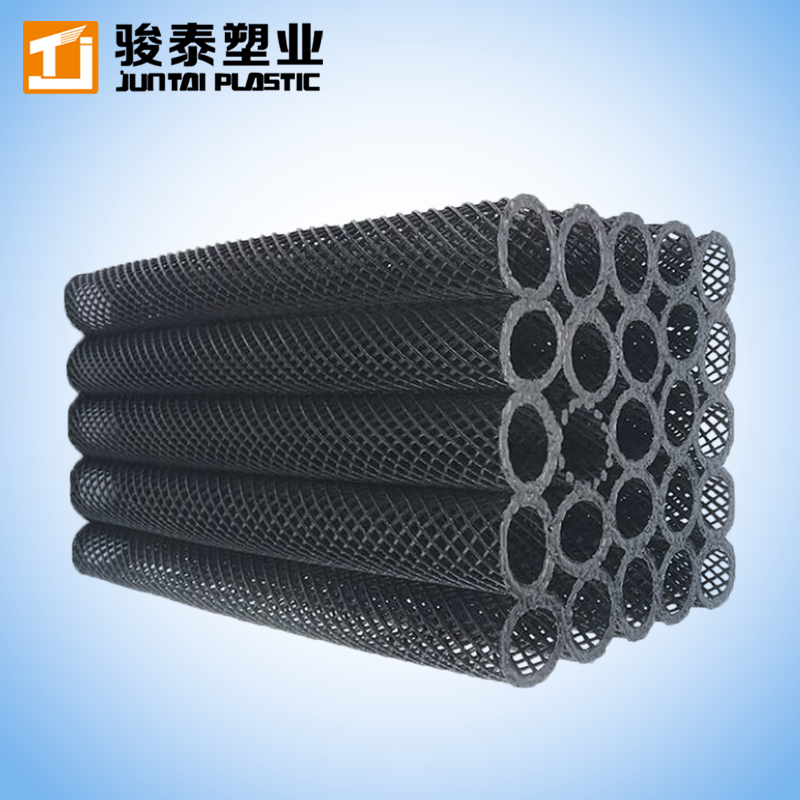

Product Parameters

| Item No. | Tube Size | Surface Area |

| Bio block 36 | 36mm | >300m2/m3 |

| Bio block 50 | 50mm | >250m2/m3 |

| Bio block 55 | 55mm | >200m2/m3 |

| Bio block 60 | 60mm | >195m2/m3 |

| Bio block 65 | 65mm | >185m2/m3 |

| Bio block 70 | 70mm | >150m2/m3 |

Bio Block Applications

1. Municipal Wastewater Treatment Plants

Primary Use: Biological nutrient removal (BNR) in activated sludge processes and MBBR/IFAS systems.

Key Benefit: Achieves 95%+ ammonia reduction in municipal sewage, meeting strict EPA/WHO discharge standards.

2. Industrial Effluent Treatment

Industries Served: Chemical, pharmaceutical, textile, and food processing plants.

Key Benefit: Resists corrosive acids/alkalis while degrading COD levels by 85%+ in high-load wastewater.

3. Recirculating Aquaculture Systems (RAS)

Species Supported: Salmon, shrimp, tilapia, and other high-density marine/freshwater farms.

Key Benefit: Removes 90%+ dissolved CO2/H2S to optimize water quality and boost fish survival rates.

4. Biogas Deaeration & Purification

Process Integration: Anaerobic digesters and biogas scrubbers.

Key Benefit: Enhances methane purity by stripping 98%+ H2S from biogas for energy generation.

5. Aquaponics & Hydroponics

System Compatibility: NFT, DWC, and media-based setups.

Key Benefit: Provides dual-phase biofiltration for nitrate stabilization, ensuring healthy crop-fish symbiosis.

6. Landfill Leachate Treatment

Challenge Addressed: High-ammonia, heavy-metal-contaminated runoff.

Key Benefit: Sustains microbial activity in pH 2-12 environments for consistent pollutant breakdown.

7. Marine Aquaculture (Offshore Cages)

Environment: Saltwater ponds and open-ocean net pens.

Key Benefit: UV-stabilized HDPE withstands seawater corrosion and typhoon conditions.

8. Petrochemical Refineries

Target Pollutants: Hydrocarbons, phenols, and sulfides.

Key Benefit: Temperature-resistant (up to 120°C) media for SBR reactors in oil wastewater treatment.

9. Municipal Drinking Water Reservoirs

Certification: NSF/ANSI 61-approved for potable water pre-treatment.

Key Benefit: Eliminates iron/manganese oxidation without chemical additives.

10. Eco-Friendly Golf Course Ponds

Aesthetic Solution: Submerged biofiltration to maintain crystal-clear water while preserving natural landscapes.

How Bio Block Works?: The Science Behind Superior Biofiltration

1. Biofilm Formation & Microbial Colonization

Step: Bio Block’s 3D high-surface-area matrix provides a scaffold for beneficial bacteria, fungi, and protozoa to attach and multiply.

Key Process: Hydrophilic surface modification accelerates biofilm growth within 24-48 hours, even in low-nutrient environments.

2. Organic Pollutant Degradation

Aerobic Treatment: In oxygen-rich zones (e.g., aeration tanks), microbes break down BOD/COD into CO2 and H2O.

Example: Removes 90%+ organic waste in municipal sewage within 6-8 hours.

Anaerobic Digestion: In biogas reactors, methanogens convert organic matter into methane, aided by Bio Block’s anti-clogging channels.

3. Nitrification/Denitrification

Nitrification: Ammonia (NH3) → Nitrites (NO2⁻) → Nitrates (NO3⁻) via autotrophic bacteria in aerobic conditions.

Denitrification: Nitrates → Nitrogen gas (N2) in anoxic zones, facilitated by Bio Block’s stratified pore structure.

Result: Achieves 95%+ ammonia removal in aquaculture RAS systems.

4. Gas-Liquid Separation (Deaeration)

Mechanism: The open-grid design creates turbulent flow to release dissolved gases (CO2, H2S) from water.

Efficiency: Reduces H2S levels by 98% in biogas scrubbers, preventing corrosion in pipelines.

5. Sludge Reduction & Energy Savings

Self-Cleaning Action: Dynamic water flow through Bio Block’s non-clogging channels minimizes sludge accumulation.

Low-Density Advantage: Requires 30% less aeration energy vs. traditional media, cutting operational costs.

Advantages of Bio Block

1.Superior Biofilm Growth

3D High-Surface-Area Design maximizes microbial colonization for faster BOD/COD removal in wastewater and aquaculture systems.

2.Engineered Durability

Made from 100% virgin HDPE/PP materials with UV stabilization and chemical resistance, ensuring 10+ years of performance in harsh environments.

3.Anti-Clogging Technology

Open-grid structure prevents sludge accumulation, reducing maintenance costs and downtime in MBBR/IFAS systems.

4.Versatile Application

Ideal for wastewater treatment plants (STPs), aquaculture RAS systems, biogas deaeration towers, and industrial effluent polishing.

5.Eco-Certified Safety

FDA/NSF-compliant materials ensure safe use in potable water and sensitive aquaculture environments (e.g., shrimp farming).

6.Energy & Cost Efficiency

Low-density design reduces aeration energy consumption by up to 30% compared to traditional ceramic/rock media.

7.Customizable Solutions

Modular units allow easy stacking and retrofitting for tanks of all sizes, from compact fish farms to large municipal plants.

8.Proven Performance

Achieves 95%+ ammonia removal efficiency in nitrification/denitrification processes, validated by third-party lab reports.

9.Global Compliance

Meets EU REACH, RoHS, and ISO 9001 standards for sustainable manufacturing and international export.

10.24/7 Technical Support

Free engineering consultation to optimize your biofiltration system design and ROI.

Why Choose Juntai for Bio Block?

As a leading manufacturer of wastewater treatment products, Juntai is committed to providing high-quality, reliable, and sustainable solutions to meet the diverse needs of our customers. Here are several compelling reasons why Juntai should be your trusted partner for Bio block:

1. Proven Expertise in Water Treatment Solutions

With years of experience in the water treatment industry, Juntai has built a reputation for delivering innovative and efficient solutions. Our team of experts understands the challenges of wastewater management and aquaculture, and we design products that meet the highest standards of performance and reliability.

2. High-Quality Manufacturing Standards

At Juntai, we use only the best materials to manufacture our Bio block products. Made from durable, corrosion-resistant plastic, our Bio blocks are built to withstand harsh water conditions, providing long-lasting performance in both wastewater treatment and aquaculture systems.

3. Customized Solutions for Diverse Applications

We recognize that each project is unique, which is why we offer tailored solutions to meet the specific needs of our clients. Whether you are dealing with municipal wastewater treatment, industrial waste, or aquaculture systems, Juntai provides Bio blocks designed to deliver optimal results in your environment.

4. Superior Performance and Efficiency

Our Bio block products are engineered to deliver outstanding performance. With their high surface area, they support the growth of beneficial microorganisms, accelerating the breakdown of pollutants and enhancing the efficiency of water treatment processes. In aquaculture, they help optimize oxygen transfer, improving the health and growth of aquatic species.

5. Commitment to Sustainability

Sustainability is at the core of our business. By choosing Juntai, you are investing in an environmentally responsible solution. Our Bio blocks are designed to promote cleaner water, reduce the environmental impact of wastewater, and contribute to the overall health of aquatic ecosystems.

6. Cost-Effective Solutions

Juntai’s Bio blocks provide a cost-effective solution for wastewater treatment and aquaculture. By enhancing the efficiency of your systems and reducing operational costs, our products deliver long-term savings, making them an ideal choice for businesses looking to optimize their water management systems.

7. Easy Installation and Low Maintenance

We design our Bio blocks for ease of installation and minimal maintenance. With their self-cleaning properties and durable structure, they require less frequent attention, allowing your systems to run smoothly with minimal downtime.

8. Reliable Global Presence

As a trusted supplier in the global market, Juntai has a strong presence across several countries. Our products are used in a wide range of industries worldwide, from municipal water treatment plants to aquaculture farms. We provide excellent customer support and ensure timely delivery of our products to meet your project needs.

9. Innovative Product Development

We continuously invest in research and development to improve the performance and efficiency of our products. Our Bio blocks are the result of ongoing innovation and technological advancements, ensuring that our customers receive the most effective solutions available.

10. Strong Customer Support

Juntai is committed to providing exceptional customer service. Our team is always available to offer technical support, answer your questions, and assist with product selection and system integration. We work closely with our clients to ensure that their projects are successful from start to finish.