+86 13600513715

+86 13600513715

In the rapidly evolving world of aerodynamics and ventilation systems, the production of an effective Aero Tube Diffuser is critical for enhancing airflow and maintaining optimal indoor environments. Understanding industry standards is essential not only for manufacturers but also for designers and end-users who require reliable and efficient solutions. This blog will provide a comprehensive checklist to guide you through the essential factors to consider when producing Aero Tube Diffusers.

By adhering to these standards, manufacturers can ensure their products deliver consistent performance, meet regulatory compliance, and satisfy customer expectations. From material selection to design considerations, each element plays a pivotal role in the final output, making this checklist a valuable resource for anyone involved in the production of Aero Tube Diffusers. Join us as we delve into the key aspects that contribute to best practices in the industry, paving the way for superior product development.

Designing aero tube diffusers requires a deep understanding of several key principles to ensure optimal performance. One primary factor is the geometry of the diffuser. The shape and size can significantly influence how air is distributed within a space. A well-designed aero tube diffuser typically features an elongated profile that promotes even airflow and minimizes turbulence. By carefully considering the angles and contours of the diffuser, engineers can enhance the efficiency of air distribution, which is critical in HVAC applications.

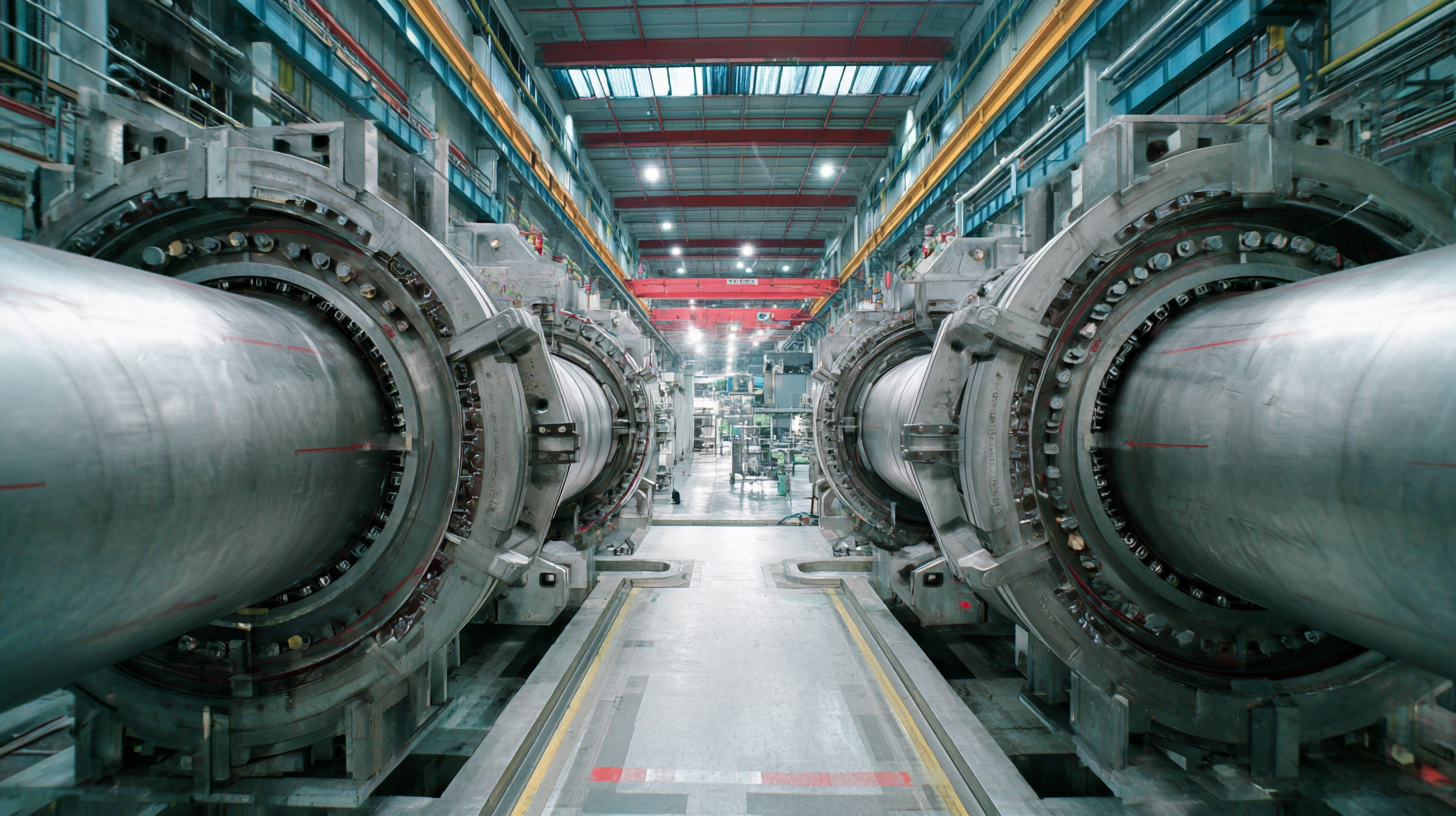

Another essential principle revolves around material selection. The choice of materials for constructing aero tube diffusers affects not only their durability but also their aerodynamics. Lightweight, high-strength materials like aluminum or certain plastics can minimize resistance and improve airflow. Additionally, incorporating features such as smooth internal surfaces helps reduce friction, allowing for a more streamlined air passage. Understanding these components and their interactions is vital for producing diffusers that meet industry standards and ensure user satisfaction in any environment.

| Dimension | Material Type | Airflow Efficiency (%) | Pressure Drop (Pa) | Noise Level (dB) |

|---|---|---|---|---|

| 600mm x 200mm | Aluminum | 85 | 120 | 45 |

| 800mm x 300mm | Steel | 90 | 110 | 42 |

| 1000mm x 400mm | Plastic | 80 | 130 | 50 |

| 1200mm x 500mm | Composite | 88 | 115 | 43 |

| 1400mm x 600mm | Alloy | 92 | 105 | 40 |

When it comes to aero tube diffusers, the choice of materials plays a crucial role in determining their durability and efficiency. Selecting high-quality materials not only enhances the performance of the diffuser but also extends its lifespan. Materials like polypropylene, aluminum, and certain engineered plastics are often favored for their resistance to corrosion and ability to withstand varying environmental conditions. It is essential to consider both the operational context and the specific requirements of the application to make an informed decision on material selection.

**Tip 1:** Always opt for materials that offer a balance between strength and weight. Lightweight materials like aluminum can reduce the overall load, improving energy efficiency, while maintaining the structural integrity needed for optimal performance.

Another factor to consider is the impact of surface finish and texture on airflow dynamics. A smooth surface can minimize drag and turbulence, leading to more efficient airflow. Conversely, some textured surfaces may be beneficial in certain applications, promoting better mixing and distribution of air.

**Tip 2:** Conduct tests or simulations to assess how different materials and finishes affect airflow. This data can guide you in choosing the best combination to enhance performance while ensuring durability.

In the competitive landscape of aero tube diffuser production, innovation in manufacturing techniques plays a crucial role. Today’s manufacturers are leveraging advanced technologies such as 3D printing, precision machining, and smart automation. These innovations not only enhance the efficiency of production processes but also ensure superior quality and consistency in every diffuser produced. By optimizing these techniques, manufacturers can significantly reduce waste and lead times, resulting in a more sustainable and cost-effective operation.

Tips: To stay ahead in the industry, focus on adopting new software tools that streamline design and production workflows. Implementing real-time monitoring systems can also help identify areas for improvement in the manufacturing process. Additionally, invest in training for your workforce to ensure they are well-versed in the latest technologies and methodologies, fostering a culture of continuous improvement.

As the industry evolves, staying updated with the latest standards and innovations is vital. Engaging with industry experts and participating in workshops can provide valuable insights into emerging manufacturing trends. By aligning production strategies with these innovations, manufacturers can create high-quality aero tube diffusers that meet or exceed industry expectations, reinforcing their position in the market.

In the production of Aero Tube Diffusers, adhering to industry standards is essential to ensure both quality and performance.

Quality control practices play a pivotal role in this process. Reports from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicate that products meeting strict quality benchmarks show a 30% improvement in efficiency compared to those that do not.

Robust quality control measures, including comprehensive testing and compliance checks, are vital for maximizing output and minimizing defects.

To effectively implement quality control practices, manufacturers should focus on several key areas. First, regular audits of production processes can help identify potential weaknesses. Implementing statistical process control (SPC) allows for real-time monitoring and enables prompt corrective actions.

Tip: Ensure all employees are trained in quality management protocols; a knowledgeable workforce is crucial for maintaining high standards.

Secondly, utilizing advanced technologies such as laser scanning for dimensional verification not only boosts accuracy but also enhances consistency across products.

Tip: Invest in modern testing equipment to streamline data collection and improve overall quality assessment.

By following these practices, manufacturers can ensure their Aero Tube Diffusers meet the rigorous industry standards necessary for success in the marketplace.

The aero tube diffuser technology is rapidly evolving, driven by the need for enhanced energy efficiency and improved indoor air quality. Recent reports indicate that the global market for diffusers is projected to grow at a compound annual growth rate (CAGR) of 8.5% from 2023 to 2028. This growth is largely attributed to advancements in design and materials that increase the performance of these systems. Innovative designs now incorporate features such as variable directions of airflow and adjustable flow rates, allowing for greater flexibility and efficiency in various applications, from residential to commercial spaces.

Moreover, sustainability has become a critical focus within the industry. A survey by the International Society of Indoor Air Quality & Climate revealed that approximately 65% of manufacturers are investing in eco-friendly materials and production processes for aero tube diffusers. This shift not only addresses environmental concerns but also aligns with the growing consumer demand for sustainable products. As building codes and regulations increasingly emphasize energy conservation and reduced carbon footprints, the implications of these emerging trends are profound, setting the stage for a new era in the design and implementation of HVAC systems that leverage the benefits of advanced aero tube diffuser technology.