+86 13600513715

+86 13600513715

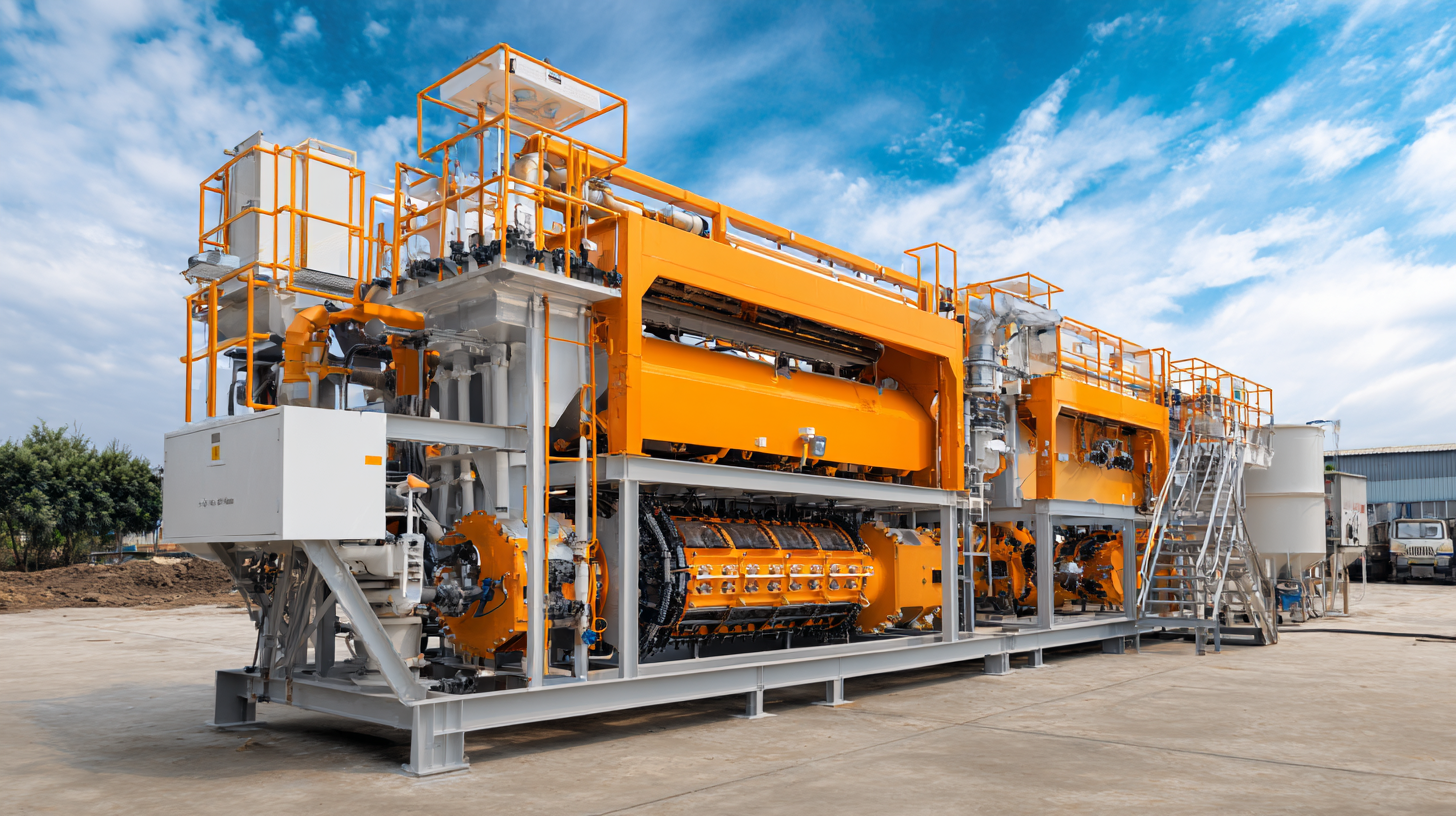

In today's rapidly evolving industrial landscape, the demand for effective wastewater management solutions has reached unprecedented levels. According to a recent report by Global Water Intelligence, the global wastewater treatment market is projected to exceed $600 billion by 2025, driven by increasing environmental regulations and the need for sustainable practices. Among the various technologies available, Screw Press Dewatering has emerged as a leading choice due to its efficiency and reliability. This innovative method not only maximizes water recovery but also minimizes energy consumption, aligning with Chinese manufacturing strengths in quality and competitiveness. With the focus on quality and China's commitment to exporting top-notch technology globally, Screw Press Dewatering stands out as an optimal solution for industries aiming to enhance their operational efficiency while supporting environmental sustainability.

Screw press dewatering technology plays a crucial role in addressing the disposal challenges faced by industries, particularly in the pork, livestock, and food processing sectors. A common issue is the high cost associated with the disposal of solids, which often necessitates investing in advanced dewatering solutions. Understanding the limitations and problems associated with screw presses—such as maintenance challenges, inconsistent feed rates, and the potential for clogging—can significantly improve operational efficiency.

To enhance the effectiveness of screw press dewatering, consider the following tips: First, ensure regular maintenance of your equipment to prevent unexpected downtimes. This includes cleaning and lubricating moving parts, which can help maintain optimal performance. Second, monitor feed quality and flow rates closely. By controlling the input consistency, you can minimize operational hiccups and reduce material waste. Lastly, invest in proper training for your operators; a well-informed team can troubleshoot issues quickly, thereby maintaining a seamless dewatering process.

Addressing common challenges within screw press dewatering not only enhances efficiency but also reduces overall costs, making it a valuable asset for businesses looking to streamline their waste management processes.

When it comes to optimizing dewatering processes with screw press technology, understanding the key factors affecting efficiency is crucial. One significant aspect is the feedstock characteristics. Variations in particle size, moisture content, and composition can greatly influence how effectively the screw press operates. For instance, a homogeneous feed with consistent moisture levels ensures a more predictable and effective dewatering process. Conversely, irregularities can lead to blockages, increased wear on machinery, and overall reduced efficiency.

Another critical factor is the operational parameters of the screw press itself. Adjusting speed, pressure, and temperature can enhance the efficiency of the dewatering process. Higher pressures may lead to better water extraction rates; however, operators must balance this with the potential for increased energy consumption and wear on the equipment. Similarly, the geometry of the screw and the design of the pressing chamber can impact performance. By fine-tuning these elements, operators can achieve significant improvements in throughput and moisture reduction, paving the way for more sustainable and effective waste treatment solutions.

Screw press dewatering technology has revolutionized the way industries manage waste and water treatment. However, like any technology, it comes with its limitations. Understanding these limitations is crucial for optimizing performance and efficiency. One common issue is the inconsistency of material feed. Variations in thickness and moisture content can lead to inefficient dewatering and increased wear on the equipment.

Screw press dewatering technology has revolutionized the way industries manage waste and water treatment. However, like any technology, it comes with its limitations. Understanding these limitations is crucial for optimizing performance and efficiency. One common issue is the inconsistency of material feed. Variations in thickness and moisture content can lead to inefficient dewatering and increased wear on the equipment.

Tip: To mitigate these issues, consider implementing automated feeding systems that can regulate the input material consistently, ensuring a uniform flow rate and minimizing disruptions in operation.

Another challenge is the buildup of solids that can occur within the screw press, affecting its performance over time. This is where innovation comes into play. Integrating self-cleaning mechanisms or utilizing advanced screw designs can help maintain operational efficiency and reduce downtime due to maintenance.

Tip: Regularly schedule maintenance and incorporate real-time monitoring technologies to detect and address blockages before they escalate into major problems, ensuring that your screw press remains effective and reliable.

Inefficient dewatering processes can lead to significant economic losses in various industries, particularly in wastewater treatment and food processing. According to the Water Environment Federation, nearly 30% of operational costs in wastewater treatment plants stem from energy and maintenance related to dewatering. This figure underscores the necessity for organizations to invest in advanced screw press dewatering technology, which offers both enhanced efficiency and reduced operational expenses.

To optimize your dewatering processes, consider implementing a comprehensive monitoring system that evaluates the performance of your equipment in real-time. This approach allows for timely interventions, reducing downtime and minimizing waste. Additionally, regular training for staff on the latest dewatering technologies can further enhance efficiency, potentially lowering overall energy costs by 15-20%, as noted in a report by the International Water Association.

Lastly, exploring partnerships with technology providers can lead to tailored solutions that maximize desiccation rates and minimize sludge volume. Transitioning to screw press systems can yield savings of up to 25% in disposal costs, proving that the upfront investment in advanced dewatering technology can pay off significantly in the long run.

| Dewatering Technology | Initial Cost ($) | Operational Cost/Year ($) | Efficiency Rate (%) | Waste Reduction (%) | Payback Period (Years) |

|---|---|---|---|---|---|

| Screw Press A | 50,000 | 15,000 | 85 | 40 | 3.67 |

| Screw Press B | 60,000 | 12,000 | 88 | 42 | 5.00 |

| Screw Press C | 70,000 | 10,000 | 90 | 45 | 3.33 |

| Screw Press D | 80,000 | 14,000 | 82 | 38 | 6.00 |

As industries continue to emphasize sustainability and resource efficiency, screw press dewatering technology is evolving rapidly. Future trends indicate a shift towards more automated and intelligent systems that not only enhance the efficiency of dewatering processes but also reduce operational costs. Innovations such as AI-based monitoring systems are set to play a significant role in optimizing performance, enabling real-time adjustments based on feed variability. This advancement will allow for better handling of different types of sludges, ensuring maximum water removal and solid recovery.

Moreover, the integration of renewable energy sources into screw press technology is becoming increasingly viable. By leveraging solar or wind energy, companies can reduce their carbon footprint while minimizing energy expenses. Research is also focusing on advanced materials for screw press components, which will enhance durability and resistance to wear, ultimately prolonging equipment life and efficacy. These advancements not only promise to improve process reliability but also align with global sustainability goals, positioning screw press technology as a front-runner in future waste management solutions.