+86 13600513715

+86 13600513715

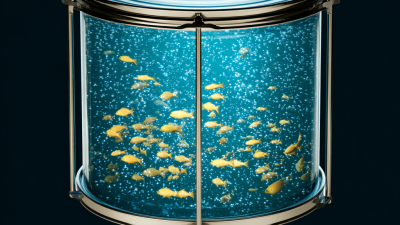

In the world of aquaculture and wastewater treatment, the efficiency of oxygen transfer is critical for optimal performance, and one of the key players in this process is the Tube Diffuser. This ultimate guide is designed to provide you with a comprehensive checklist to master the use of tube diffusers, ensuring that every aspect of their operation maximizes your system's potential. From understanding the various types of tube diffusers available in the market to their installation and maintenance, this guide will walk you through the essential steps needed to enhance performance and efficiency. Whether you're a seasoned professional or new to the field, our detailed insights and straightforward checklist will equip you with the knowledge required to harness the full capabilities of tube diffusers, thereby promoting healthier aquatic environments and more effective wastewater management.

Tube diffusers are essential components in various applications, notably in aeration systems for wastewater treatment and aquaculture. Understanding the different types and technologies of tube diffusers is crucial for achieving optimal performance. The most common types include membrane diffusers, ceramic diffusers, and perforated pipe diffusers, each offering unique advantages. Membrane diffusers are known for their efficiency in oxygen transfer and adaptability to changing conditions, while ceramic diffusers showcase durability and resistance to fouling, making them ideal for harsher environments. Perforated pipe diffusers, on the other hand, provide a cost-effective solution for large-scale operations.

Tube diffusers are essential components in various applications, notably in aeration systems for wastewater treatment and aquaculture. Understanding the different types and technologies of tube diffusers is crucial for achieving optimal performance. The most common types include membrane diffusers, ceramic diffusers, and perforated pipe diffusers, each offering unique advantages. Membrane diffusers are known for their efficiency in oxygen transfer and adaptability to changing conditions, while ceramic diffusers showcase durability and resistance to fouling, making them ideal for harsher environments. Perforated pipe diffusers, on the other hand, provide a cost-effective solution for large-scale operations.

In recent years, advancements in technology have led to the development of more sophisticated tube diffuser systems. Innovations such as fine bubble technology allow for increased surface area for oxygen absorption, significantly enhancing the efficiency of aeration processes. Additionally, the integration of smart monitoring systems enables real-time performance tracking, which helps in fine-tuning operations and reducing energy consumption. By understanding the nuances of these technologies, operators can select the appropriate tube diffuser model to meet specific project goals, ensuring long-term sustainability and efficiency in their processes.

When evaluating the efficiency of tube diffusers, it's crucial to focus on various performance metrics that determine their effectiveness in aeration processes. First, the Oxygen Transfer Efficiency (OTE) is a primary metric, reflecting how well the diffuser transfers oxygen from the air into the water. A higher OTE indicates that less energy is needed for aeration, directly impacting operational costs and energy efficiency. Additionally, the System Type and its configuration play significant roles, as some setups naturally optimize the performance of tube diffusers more than others.

Moreover, Bubble Size Distribution (BSD) is another vital performance metric to consider. Smaller bubbles generally enhance surface area, leading to better gas exchange and faster oxygen absorption rates. Therefore, understanding how different tube designs and materials influence BSD is essential for achieving optimal performance. Additionally, monitoring the fouling rates can provide insights into long-term efficiency; when diffuser surfaces become clogged with biofilm, performance decreases sharply. Regular maintenance and selection of appropriate materials can mitigate these issues, ensuring sustained performance of tube diffusers in various applications.

In the realm of wastewater treatment, the choice of aeration system can significantly impact the biological decomposition process of organic compounds. A comparative analysis of aeration performance across different diffuser types reveals that fine bubble diffusers generally offer superior oxygen transfer efficiency compared to larger bubble systems. Notably, intermittent aeration strategies have emerged as a more sustainable option than their continuous counterparts, promoting energy conservation while maintaining effective biological activity.

Tips for optimizing aeration performance include regularly monitoring dissolved oxygen (DO) levels to ensure aerobic conditions are met. It's essential to adjust the airflow rates in accordance with the specific requirements of your treatment system and the characteristics of the wastewater being processed. Additionally, exploring advanced technologies like AI-driven predictive models can enhance the efficiency of aeration strategies by providing data-driven insights for better decision-making.

Understanding the oxygen-transfer capacity and its relationship with different diffuser setups allows operators to make informed choices. Experimenting with different aeration methods, such as membrane bubble units, can help identify the best fit for specific treatment goals, ultimately leading to improved performance and sustainability in wastewater management.

| Diffuser Type | Oxygen Transfer Efficiency (%) | Pressure Drop (mbar) | Optimal Operating Depth (m) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Ceramic Diffuser | 45-55 | 20 | 3-5 | 12 |

| Membrane Diffuser | 30-40 | 15 | 2-4 | 6 |

| Sintered Metal Diffuser | 50-60 | 25 | 3-5 | 24 |

| Plastic Tube Diffuser | 25-35 | 10 | 1-3 | 18 |

| Rotary Atomizer | 55-65 | 30 | 4-6 | 36 |

The choice of material in tube diffusers is crucial for optimizing both performance and longevity, particularly in activated sludge systems. Recent studies on Shell Fiber Reinforced Polyester (SFRP) have demonstrated its effectiveness in enhancing diffuser lifespan while minimizing fouling. SFRP's durability allows it to withstand harsh operational environments, reducing maintenance costs and downtime often associated with material degradation. By utilizing advanced composite materials, facilities can ensure that their diffusers maintain consistent performance over extended periods, leading to improved aeration efficiency.

Moreover, the impact of biofilm growth on diffuser performance cannot be overlooked. As biofilm accumulates, it affects airflow and oxygen transfer rates, ultimately influencing the overall effectiveness of the aeration system. Research has established a robust connection between biofilm DNA concentrations and the reduction in aeration efficiency, suggesting that monitoring bioload can serve as a predictive tool for maintenance scheduling. By understanding these relationships, operators can take proactive measures to manage biofilm formation, thus enhancing the operational reliability of fine-pore diffusers in their wastewater treatment processes.

When considering the integration of tube diffusers in your system, a cost-benefit analysis becomes essential to ensure optimal performance without overspending. Research indicates that investing in high-quality tube diffusers can yield a significant return on investment. For instance, a study conducted by the Water Environment Federation reports that systems equipped with advanced tube diffusers can achieve oxygen transfer efficiencies of up to 90%, compared to 70% in traditional systems. This improvement not only enhances the treatment capacity of wastewater facilities but also reduces energy consumption, providing long-term operational savings.

Moreover, the selection of tube diffusers should also factor in their lifespan and maintenance costs. According to industry data from the American Society of Civil Engineers, the average lifespan of a tube diffuser can range from 5 to 15 years, with proper maintenance extending this period significantly. Choosing the right diffuser can impact not just the initial setup costs but also the ongoing expenses related to repairs and replacements. Therefore, conducting a thorough cost-benefit analysis that includes these elements will enable facilities to make informed decisions that align their operational goals with budgetary constraints. By understanding the financial implications of different options, you can select a tube diffuser that maximizes both performance and economic value.