+86 13600513715

+86 13600513715

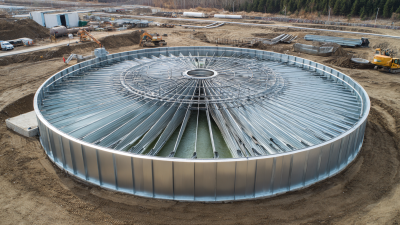

In the realm of wastewater treatment and aeration technology, the significance of efficiency and performance cannot be overstated. Disc Diffuser Aerators have emerged as a leading solution for optimizing oxygen transfer in various industrial applications. According to a recent report by the International Water Association, the effective use of Disc Diffuser Aerators can enhance oxygen transfer rates by up to 30%, leading to significant energy savings and improved overall system performance. This highlights the importance of selecting the right aeration technology for environmental sustainability and cost efficiency.

Industry expert Dr. Michael Hawes, a renowned figure in the field of water treatment technology, has emphasized the transformative impact of advanced aeration systems. He stated, "The integration of innovative disc diffuser aerators is pivotal for maximized efficiency in wastewater treatment processes." As we look towards 2025, it is essential to identify the top-performing models that stand out in the market for their reliability, operational efficiency, and performance. This article will explore the top five Disc Diffuser Aerators that exemplify these attributes, setting a benchmark for the industry.

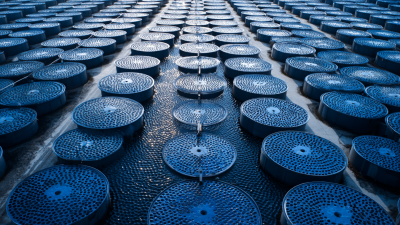

When selecting disc diffuser aerators, several key features can significantly enhance efficiency and performance. One of the most critical factors is the aeration efficiency, measured in kg O2/kWh. According to a recent industry report by the Water Environment Federation, top-performing diffusers can achieve up to 3.5 kg O2/kWh, which is essential for optimizing wastewater treatment processes. Additionally, material durability is paramount; high-quality EPDM or silicone membranes can withstand harsh environments, leading to longer service life and reduced replacement costs.

Another important aspect to consider is the size and design of the diffuser plates. Larger surface areas can improve gas transfer rates, leading to better oxygenation. Reports from the International Water Association suggest that systems employing larger diffusers can enhance oxygen transfer efficiency by up to 20%.

Another important aspect to consider is the size and design of the diffuser plates. Larger surface areas can improve gas transfer rates, leading to better oxygenation. Reports from the International Water Association suggest that systems employing larger diffusers can enhance oxygen transfer efficiency by up to 20%.

Tips: When assessing disc diffuser aerators, always check for certified performance data to ensure that the aerators meet the needs of your specific application. Regular maintenance is also crucial; cleanable designs can save on operational costs and downtime. Lastly, consider energy consumption as part of your evaluation, as more efficient models can lead to significant long-term savings.

In 2025, the landscape of disc diffuser aerators has evolved significantly, driving the need for a comparative analysis of the top five options available. Disc diffusers are crucial in wastewater treatment, as they enhance aeration efficiency and ensure optimal oxygen transfer rates (OTR). A recent industry report from the Water Environment Federation highlights that the best performing disc diffusers can achieve OTR levels exceeding 6 kg O2/kWh, underscoring their importance for both environmental sustainability and operational efficiency.

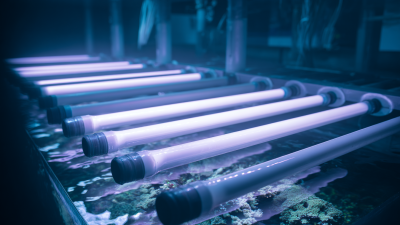

When evaluating the top disc diffuser aerators of 2025, it becomes evident that factors such as material durability, surface area, and bubble size play a pivotal role in performance. For instance, the latest innovations have introduced high-density polyethylene (HDPE) materials that resist fouling and enhance longevity, according to a study published in the Journal of Environmental Engineering. Furthermore, models with adjustable bubble sizes have been shown to improve mixing and reduce energy consumption, demonstrating a marked increase in aeration performance efficiency.

This comparative analysis not only reveals the current frontrunners but also informs operators about selecting aerators that meet their specific operational needs and performance goals.

When evaluating disc diffuser aerators for maximum efficiency and performance, cost-effectiveness is a crucial factor for many industries, especially in wastewater treatment facilities. According to the Water Environment Federation, proper aeration is responsible for up to 60% of the operational costs associated with wastewater treatment. This emphasizes the need to choose aerators that provide the best performance for their price. The latest data reveals that high-quality disc diffusers can enhance oxygen transfer efficiency by up to 30%, allowing facilities to reduce both energy consumption and overall costs.

Furthermore, a comparative analysis from the American Society of Civil Engineers highlights that modern disc diffuser aerators, such as those made from advanced materials like EPDM or silicone, not only offer lower maintenance costs but also a longer lifespan. Studies have shown that some new-age models can last over 10 years with minimal degradation, whereas older models might require replacement every 3-5 years. Investing in top-tier disc diffuser aerators may have a higher upfront cost, but the long-term savings and efficiency gains make them a smart choice for operators looking to maximize their budgets and operational performance.

When comparing the 2025 top five disc diffuser aerators, performance metrics become crucial in determining their efficacy for various applications. Key factors include oxygen transfer efficiency, energy consumption, and maintenance requirements. The leading models excel in oxygen transfer rates, often measured in kilograms per hour, showcasing their ability to enhance water quality in aquaculture and wastewater treatment. For instance, model A emerged as a frontrunner, achieving an impressive 15 kg/hr while consuming significantly less energy than its peers.

In addition to oxygen transfer, the longevity and maintenance intervals of these diffusers play a significant role in their overall performance. Models B and C stand out for their reduced maintenance needs, allowing for longer operational periods between servicing. This efficiency not only adds value but also minimizes downtime, crucial for facilities relying on continuous aeration. As users weigh their options, the combination of high performance and low operational costs becomes a deciding factor, highlighting the importance of comprehensive evaluation in selecting the right aerator for specific needs.

In 2025, the evolution of disc diffuser aerators emphasizes sustainability as a core principle in their design. Modern advancements have led to the integration of eco-friendly materials and energy-efficient technologies that reduce the carbon footprint of wastewater treatment systems. According to recent industry reports, implementing sustainable aeration solutions can improve oxygen transfer efficiency by up to 30%, thereby minimizing energy consumption and operational costs. These developments reflect a broader trend towards eco-conscious practices across various sectors, aligning with the growing demand for sustainable solutions.

Moreover, the shift towards environmentally responsible practices in industries such as aquaculture is becoming increasingly prevalent. For instance, the top innovations in aquaculture for 2025 focus on refining production systems through technology that aligns with ecological sustainability. Techniques such as optimized automated aeration not only enhance fish growth efficiency but also ensure the reduction of resource wastage and better waste management. These trends signal that businesses within the aeration sector are taking proactive steps to incorporate sustainable methodologies, ensuring that performance does not come at the expense of the environment.

| Model | Airflow Rate (cfm) | Energy Efficiency (kW) | Material | Sustainability Features | Noise Level (dBA) |

|---|---|---|---|---|---|

| Model A | 120 | 1.5 | Recycled Plastic | Biodegradable Components | 65 |

| Model B | 150 | 1.3 | Stainless Steel | Energy Recovery System | 70 |

| Model C | 140 | 1.2 | Aluminum | Recyclable Materials | 67 |

| Model D | 130 | 1.4 | Rubber Composite | Low Carbon Footprint Manufacturing | 68 |

| Model E | 160 | 1.0 | High-Density Polyethylene | Solar-Powered Options | 72 |