+86 13600513715

+86 13600513715

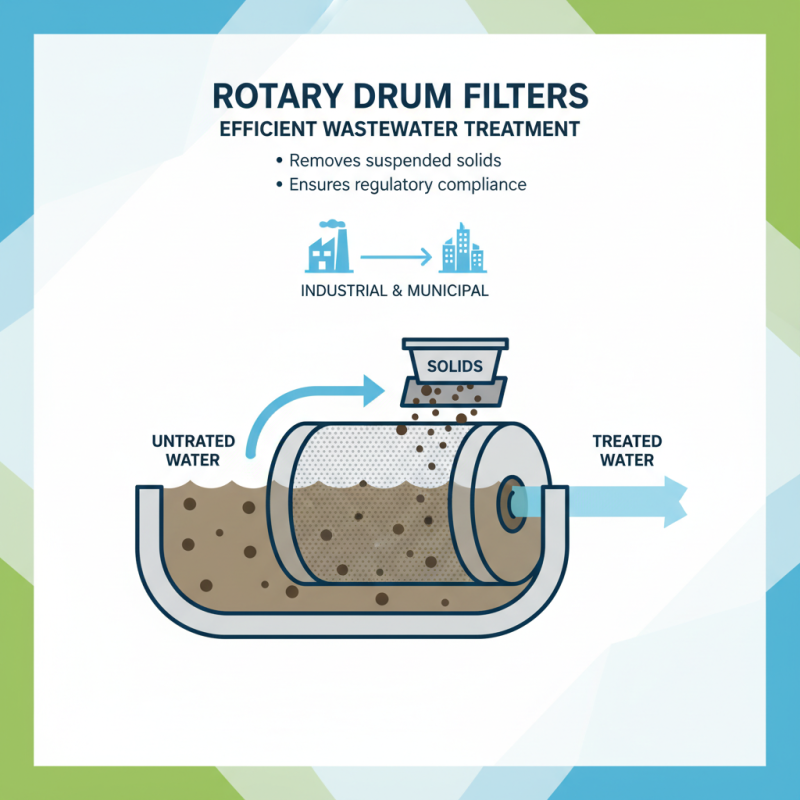

In recent years, the demand for efficient wastewater treatment solutions has escalated, driven by increasing industrialization and stringent environmental regulations. Among the various technologies available, the Rotary Drum Filter has emerged as a premier choice for many industries. This filtration technology operates on a continuous basis, offering advantages in terms of maintenance, efficiency, and operational costs. According to a report by the Environmental Protection Agency (EPA), the implementation of advanced filtration systems like Rotary Drum Filters can lead to a reduction of suspended solids by up to 95%, significantly improving water quality.

Dr. Emily Carter, a leading expert in wastewater management, emphasizes the importance of choosing the right filtration technology. She notes, “The efficiency of a Rotary Drum Filter not only enhances the treatment process but also minimizes the environmental impact, making it a smart investment for industries looking to comply with regulatory standards.” As industries strive to balance operational efficiency with environmental responsibility, the Rotary Drum Filter offers a robust solution that integrates effectively within existing treatment infrastructures. This makes it an optimal choice for those committed to sustainable practices in wastewater management.

Rotary drum filters have emerged as a preferred choice in wastewater treatment due to their efficiency and effectiveness in separating solids from liquids. One of the primary advantages of these filters is their continuous operation, which allows for a steady flow of wastewater while maintaining consistent filtration performance. The design incorporates a rotating cylindrical screen that captures particulate matter, ensuring optimal filtering without interruption. This continuous process not only enhances productivity but also reduces the need for manual intervention, leading to lower operational costs and increased efficiency.

Furthermore, rotary drum filters excel in their ability to handle varying flow rates and varying concentrations of solids. This adaptability makes them suitable for diverse wastewater applications, from municipal treatment plants to industrial effluent management. Their self-cleaning mechanism minimizes maintenance efforts, as the rotation facilitates the removal of trapped solids, preventing clogging and ensuring sustained filtration efficiency. Additionally, the use of rotary drum filters can lead to improved effluent quality, as they provide fine filtration that can significantly reduce suspended solids and solid waste, contributing to better compliance with environmental regulations.

Rotary drum filters are increasingly favored in wastewater treatment facilities due to their impressive efficiency and operational benefits. One standout feature of these systems is their high throughput capacity, allowing for substantial volumes of wastewater to be processed in a compact footprint. This is particularly advantageous in urban areas where space is limited. The continuous filtration cycle of rotary drum filters also minimizes downtime, ensuring consistent operation and optimal system performance.

Additionally, the design of rotary drum filters facilitates effective solids removal, which is crucial for maintaining water quality. The filters employ a mesh screen that separates solids from liquids, while self-cleaning mechanisms prevent clogging, thus enhancing the system's longevity and reducing maintenance needs. Importantly, the automatic backwashing feature ensures that the filter remains in optimal working condition without the need for frequent manual intervention.

Tips: When selecting a rotary drum filter for your wastewater treatment needs, consider factors such as the size of your facility and the volume of wastewater generated. Regular monitoring and maintenance can significantly extend the lifespan of the equipment, ensuring it operates at maximum efficiency. Moreover, training staff on the operational intricacies can lead to even better performance results.

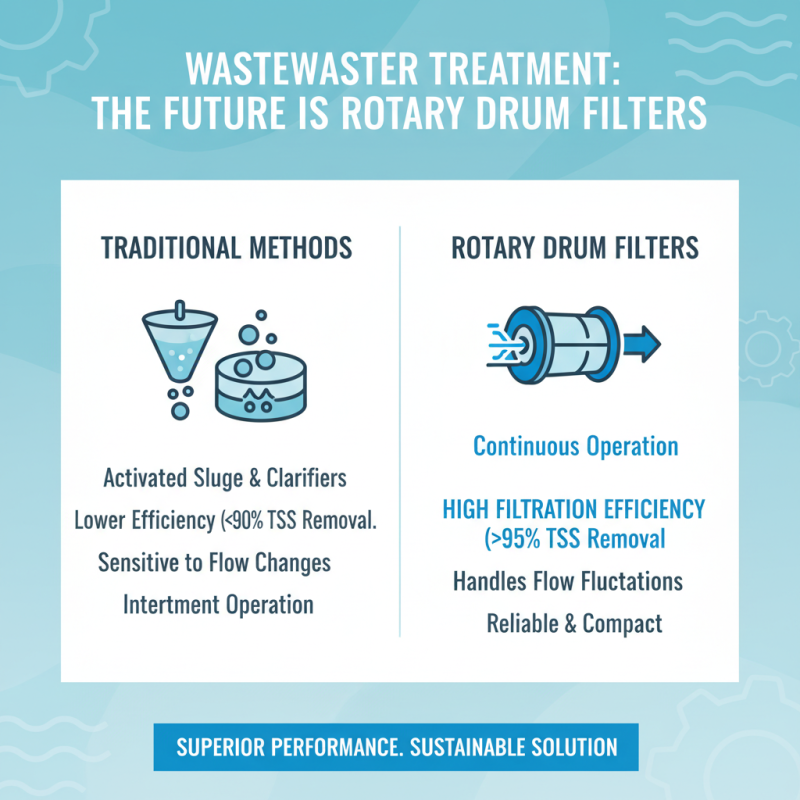

Rotary drum filters are increasingly becoming the favored choice for wastewater treatment, particularly when compared to traditional methods such as activated sludge and clarifiers. One of the major advantages of rotary drum filters is their ability to provide continuous operation and high filtration efficiency. According to a report by the Water Environment Federation, rotary drum filters can achieve solids capture rates exceeding 95%, significantly outperforming some conventional methods which can struggle to achieve similar efficiency, especially in varying flow conditions. This ability to manage fluctuations in influent quality makes rotary drum filters a reliable option for modern wastewater treatment facilities.

Moreover, rotary drum filters have a smaller footprint compared to traditional treatment processes. This is particularly beneficial for municipalities facing space constraints. The compact design allows for easier integration into existing systems or new installations. Additionally, the automatic cleaning mechanisms employed in rotary drum filters reduce the operational costs and labor associated with manual cleaning required by some traditional methods. According to industry studies, facilities that switched to rotary drum technology noted a decrease in maintenance costs by up to 30% over a five-year period.

Tip: When evaluating wastewater treatment solutions, consider not just the upfront costs but also the long-term operational efficiency and maintenance requirements. The initial investment in rotary drum filters may yield substantial savings over time due to reduced labor and enhanced performance. Another tip is to analyze the specific requirements of your facility, as the size and scale of operations can greatly influence the suitability of rotary drum filters versus traditional methods.

Rotary drum filters play a pivotal role in wastewater treatment across various industries due to their efficiency and adaptability. In municipal wastewater treatment plants, these filters are used to remove suspended solids and other contaminants, ensuring that the treated water meets regulatory standards for discharge. By utilizing a rotating drum covered with a filter medium, these systems can continuously separate solids from liquids, allowing for a more streamlined and effective cleaning process.

In industrial applications, rotary drum filters are essential for sectors such as food and beverage, pharmaceuticals, and mining. In the food industry, for instance, they efficiently filter out solids from wastewater generated during production, maintaining hygiene and quality standards. The pharmaceutical sector benefits from their ability to produce high-quality effluent that aligns with strict environmental regulations. Additionally, in mining operations, these filters assist in reclaiming water from tailings, ensuring that valuable resources are not wasted while minimizing environmental impact. The versatility and reliability of rotary drum filters make them a preferred choice for enhancing operational efficiency across multiple industries.

Regular maintenance is crucial for ensuring the optimal performance of rotary drum filters in wastewater treatment systems. One of the primary maintenance considerations involves monitoring the filter's screen integrity. Over time, the mesh can become clogged with debris, leading to reduced filtration efficiency and potential system overloads. Routine inspections should include checking for tears or blockages in the screen, as well as cleaning procedures to remove accumulated solids. Effective cleaning methods, such as backwashing or manual scraping, can help maintain high flow rates and extend the lifespan of the filter.

Another key aspect of maintenance is the lubrication of moving parts. Rotary drum filters typically involve mechanical components that require regular lubrication to minimize wear and ensure smooth operation. Operators should establish a lubrication schedule based on the manufacturer's guidelines and environmental conditions. Additionally, monitoring the motor and drive system for unusual vibrations or noises can prevent unexpected breakdowns. By prioritizing these maintenance practices, facilities can enhance the reliability and efficiency of rotary drum filters, ultimately leading to improved wastewater treatment outcomes.