+86 13600513715

+86 13600513715

Screw Press Dewatering has emerged as a critical technology in various industries, particularly in waste treatment and resource recovery processes. According to a recent report by the Global Water and Wastewater Treatment Market, the adoption of efficient dewatering technologies could enhance operational efficiency and reduce sludge disposal costs by up to 50%. Additionally, industry studies indicate that Screw Press Dewatering systems not only improve solid-liquid separation but also require significantly less energy compared to traditional methods, translating to substantial cost savings.

As organizations increasingly prioritize sustainable practices and operational efficiency, optimizing Screw Press Dewatering systems becomes paramount. This optimization involves refining the mechanical and operational parameters to achieve the best performance outcomes, which not only conserves resources but also aligns with industrial goals of minimizing environmental impact.

Through targeted strategies, facilities can harness the full potential of Screw Press Dewatering, driving both economic and ecological advancements in their operations.

As organizations increasingly prioritize sustainable practices and operational efficiency, optimizing Screw Press Dewatering systems becomes paramount. This optimization involves refining the mechanical and operational parameters to achieve the best performance outcomes, which not only conserves resources but also aligns with industrial goals of minimizing environmental impact.

Through targeted strategies, facilities can harness the full potential of Screw Press Dewatering, driving both economic and ecological advancements in their operations.

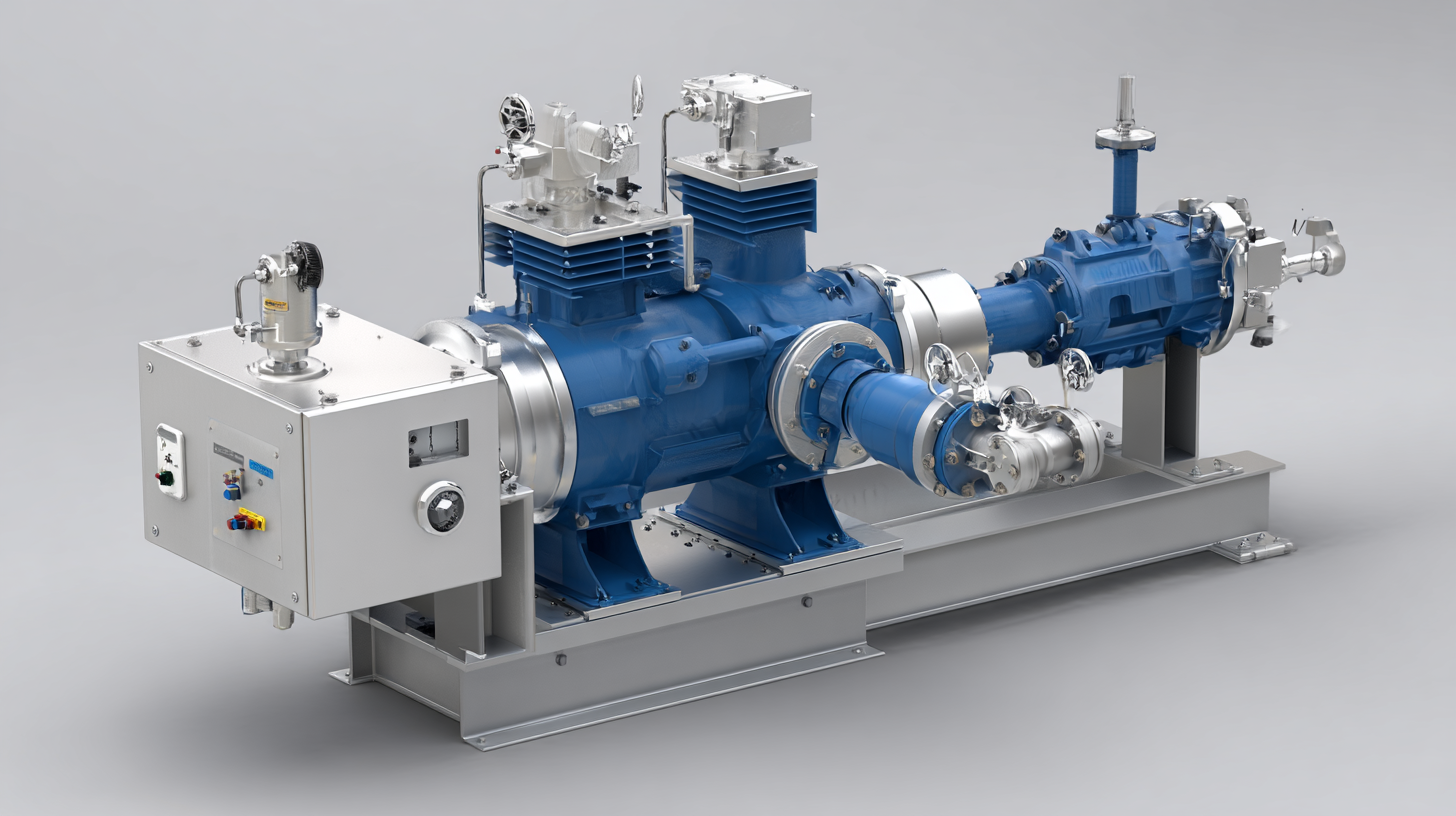

Screw press dewatering technology has emerged as a pivotal solution for industries looking to maximize efficiency and reduce operational costs. At its core, the screw press uses a rotating screw to separate liquids from solids in a continuous process. This mechanism capitalizes on the application of pressure, enabling efficient dewatering while minimizing energy consumption. Understanding the fundamental principles behind this technology is crucial for those seeking to enhance their systems.

To optimize screw press dewatering systems, it is essential to evaluate the design of the screw press, the material properties, and the operational parameters. Factors such as the screw diameter, pitch, and rotation speed directly influence dewatering performance. Moreover, pre-treatment processes, like screening and conditioning, can significantly affect the volume and consistency of the feed material, ultimately impacting the efficiency of the dewatering operation. By mastering these basics, operators can implement targeted improvements that lead to significant cost savings and enhanced productivity in their dewatering processes.

When optimizing screw press dewatering systems, it is essential to assess key performance indicators (KPIs) to ensure maximum efficiency and cost savings. KPIs such as moisture content of the dewatered cake, throughput rate, and energy consumption are critical metrics that help operators gauge the effectiveness of their systems. For instance, industry studies suggest that maintaining an optimal moisture content of around 80% can significantly enhance the dry solids recovery, thus reducing disposal costs.

Additionally, monitoring the throughput rate is crucial; it is reported that increasing this rate by just 10% can lead to a 15% reduction in operational costs.

Energy consumption is another vital KPI that should not be overlooked. Data indicates that modifications in the process, including the implementation of variable frequency drives, can reduce energy usage by up to 20%, thus contributing to overall cost savings. By focusing on these KPIs, facilities can achieve not only enhanced performance in their screw press dewatering systems but also long-term sustainability in their operations.

Regular maintenance practices are essential for optimizing screw press dewatering systems, ensuring maximum efficiency while minimizing downtime and costs. By implementing a structured maintenance schedule, facilities can proactively identify potential issues before they escalate into costly breakdowns. Routine inspections, cleaning, and timely replacements of worn components play a crucial role in maintaining the operational integrity of these systems. Emphasizing preventative measures reduces the likelihood of unplanned outages, thereby enhancing productivity and saving significant costs associated with emergency repairs.

Regular maintenance practices are essential for optimizing screw press dewatering systems, ensuring maximum efficiency while minimizing downtime and costs. By implementing a structured maintenance schedule, facilities can proactively identify potential issues before they escalate into costly breakdowns. Routine inspections, cleaning, and timely replacements of worn components play a crucial role in maintaining the operational integrity of these systems. Emphasizing preventative measures reduces the likelihood of unplanned outages, thereby enhancing productivity and saving significant costs associated with emergency repairs.

Additionally, integrating advanced monitoring technologies can further streamline maintenance practices. Utilizing IoT solutions allows for real-time data collection and analysis, offering insights into system performance. This capability enables maintenance teams to make informed decisions, optimizing the timing of maintenance activities based on actual operating conditions rather than relying solely on predetermined schedules. As industries strive for higher efficiency and cost-effectiveness, adopting these innovative maintenance strategies will prove vital in sustaining competitive advantage in the market.

Advanced control systems play a pivotal role in optimizing the operation of screw press dewatering systems, significantly enhancing process management and improving overall efficiency. According to a report by the American Society of Agricultural and Biological Engineers, integrating advanced automation technologies can increase dewatering efficiency by up to 30%. These systems utilize real-time data monitoring and adaptive algorithms to adjust operational parameters dynamically, ensuring that the screw press operates at peak performance under varying load conditions.

Moreover, employing predictive maintenance techniques through advanced control systems can lead to substantial cost savings. A study from the Water Environment Federation highlights that predictive maintenance can reduce system downtime by 20-30% and lower maintenance costs by approximately 15%. By leveraging data analytics and machine learning, facilities can forecast potential failures and optimize maintenance schedules, further enhancing the longevity and reliability of screw press systems. Thus, investing in advanced control technologies not only boosts operational efficiency but also provides a significant return on investment through cost savings and improved process outcomes.

This chart compares the energy consumption and water output of different screw press dewatering systems. It highlights the efficiency in terms of energy used per cubic meter of water processed, providing insights for optimizing operations.

Energy consumption is a critical factor in the overall cost efficiency of screw press dewatering systems. By evaluating the energy usage patterns, operators can identify key areas where energy efficiencies can be achieved. This involves closely monitoring the power ratings of the motors used in the system and assessing the operational times to understand how energy consumption correlates with varying loads and sludge characteristics. Implementing energy-efficient motors and optimizing operational schedules can lead to significant reductions in energy costs without compromising the performance of the dewatering process.

Moreover, regular maintenance of the equipment plays a pivotal role in minimizing energy wastage. Dirty or worn-out components can lead to increased friction and subsequently higher energy consumption. By ensuring that the screw press and its ancillary systems are well-maintained, facilities can operate at peak efficiency. Additionally, integrating technology, such as variable frequency drives (VFDs), can further enhance control over energy use, allowing systems to adjust to the demand dynamically. Each of these strategies contributes to a more sustainable and cost-effective operation, showcasing that careful evaluation of energy use is not just beneficial but essential in optimizing screw press dewatering systems.