+86 13600513715

+86 13600513715

The effective optimization of Rotating Drum Filters (RDFs) is crucial in various industries, particularly in waste treatment and aquaculture, where efficient filtration plays a key role in operational success. According to a recent industry report by Global Market Insights, the market for water and wastewater filtration systems, including RDFs, is expected to reach over $17 billion by 2025, driven by increasing regulatory requirements and the need for sustainable practices. Enhancing the performance of these systems not only aids in compliance with environmental standards but also significantly reduces operational costs. Studies indicate that optimizing the design and operation parameters of RDFs can lead to a 30% improvement in filter throughput and a reduction in backwash frequency, ultimately increasing throughput and extending the lifespan of the equipment. As the demand for efficient filtration solutions continues to rise, understanding how to optimize the functionality of Rotating Drum Filters becomes imperative for industry leaders aiming to maintain competitive advantages.

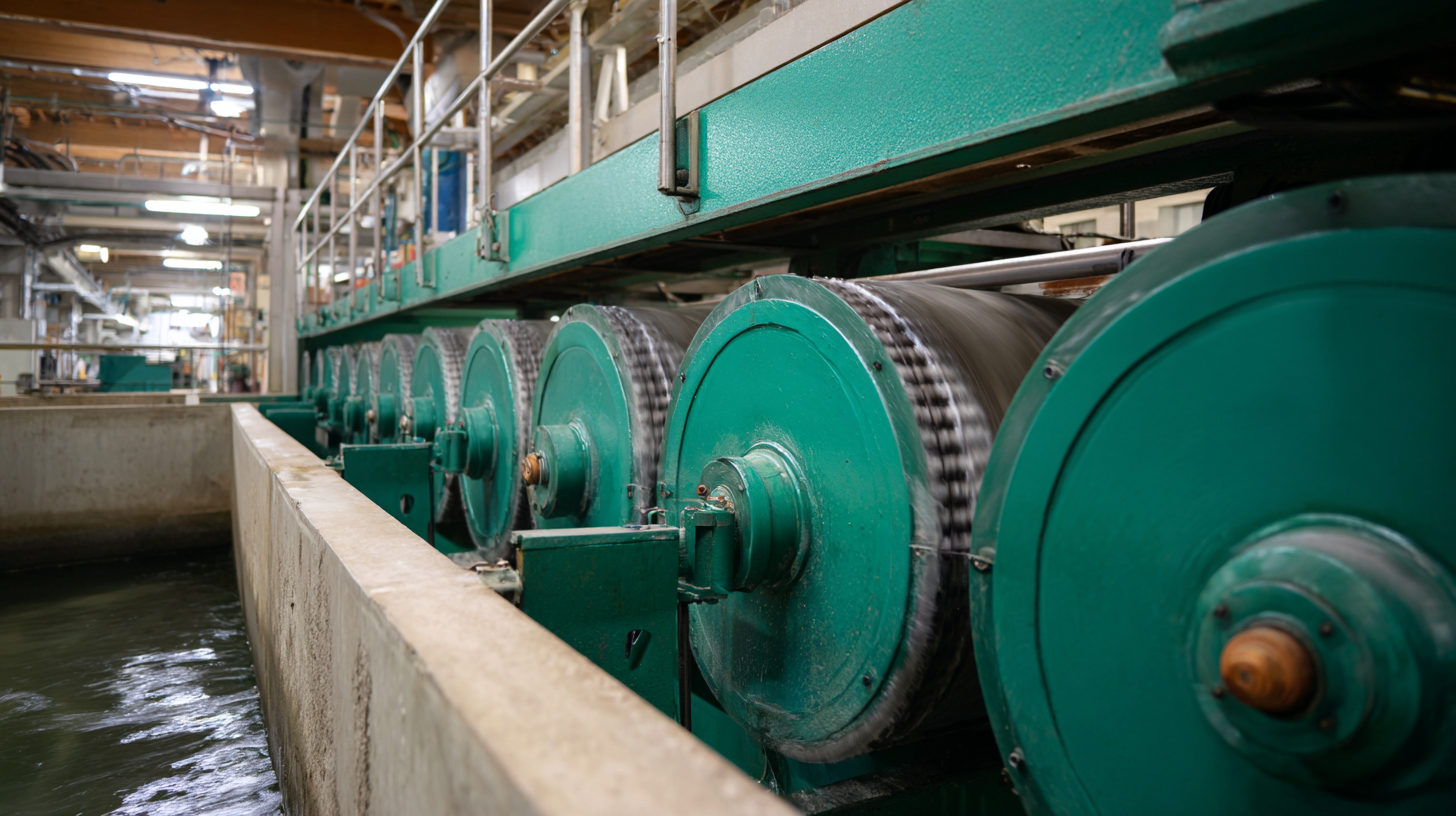

The efficiency of a rotating drum filter greatly depends on its key components. First and foremost, the drum itself plays a critical role. The design and material of the drum should facilitate optimal flow and filtration, ensuring that solids are efficiently removed while allowing filtered water to pass through. Regular inspection and maintenance of the drum surface, including cleaning to prevent clogging, are essential for maintaining performance.

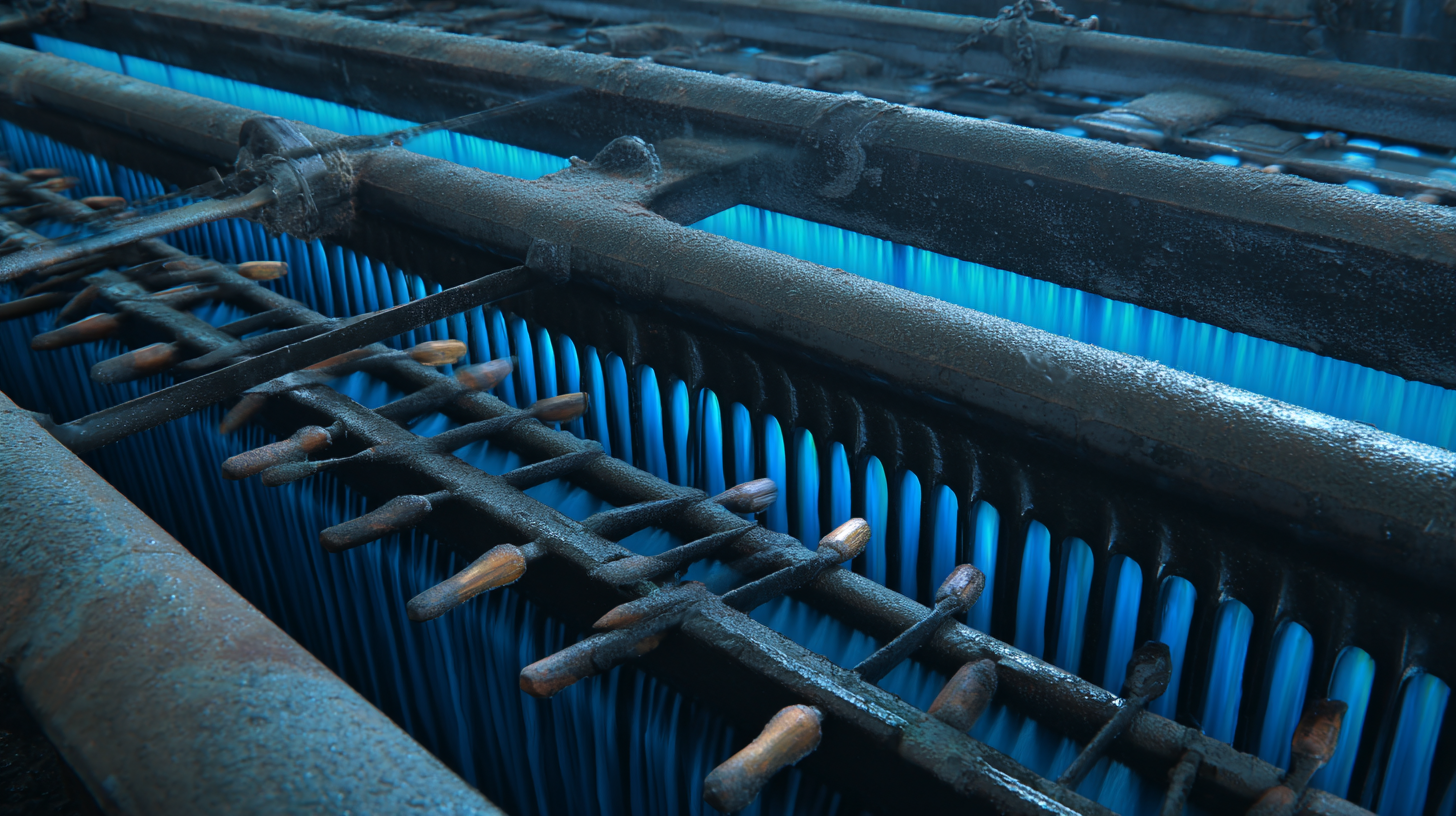

Another vital component is the drive mechanism. The motor and gearbox should be properly calibrated to ensure the drum rotates at an optimal speed, which enhances the filtration process without causing excessive wear or energy consumption. Additionally, the filtration media, which can vary in texture and porosity, should be selected carefully based on the specific application to maximize the filter's effectiveness. By focusing on these elements—drum design, drive mechanism, and filtration media—operators can significantly enhance the efficiency and longevity of their rotating drum filters.

Regular maintenance practices are essential to ensure the longevity and optimal performance of your rotating drum filter. By implementing a structured maintenance schedule, operators can significantly reduce the risk of unexpected failures and extend the service life of the equipment. Routine tasks such as inspecting the drum for wear, cleaning the filter media, and checking the alignment and operational settings can help maintain efficiency. Additionally, keeping an eye on the mechanical components can prevent minor issues from escalating into costly repairs.

Recent advancements in rotary screen technology have emphasized the importance of easy maintenance. Innovations like a pivot mount design have simplified maintenance procedures, making it easier for operators to perform necessary upkeep with minimal downtime. This not only streamlines the maintenance process but also enhances the overall effectiveness of municipal wastewater treatment systems. By adopting such innovations and prioritizing regular maintenance, facilities can achieve better performance from their drum filters while ensuring reliable operation in the long run.

To achieve optimal filtration performance with a rotating drum filter, it is essential to focus on adjusting operational parameters that directly influence its efficiency. The filtration rate is greatly affected by the speed of the drum. By fine-tuning the rotation speed, operators can find a balance that allows for adequate retention time of the wastewater against the filter mesh, ensuring that solids are effectively captured while minimizing energy consumption.

Another critical parameter is the backwashing frequency, which helps maintain the filter's clarity. A well-timed backwashing process prevents clogging and ensures that the filter remains operational without excessive downtime. Operators should monitor the pressure differential across the filter media regularly to adjust the backwash cycles aptly. Additionally, maintaining the correct chemical dosing in the feed can enhance particle removal and improve the overall filtration efficiency, making it vital to analyze the characteristics of the incoming wastewater continuously. By adjusting these parameters, operators can optimize the performance of their rotating drum filter, ensuring consistency and reliability in their wastewater treatment processes.

Rotating drum filters are essential in various industries for maintaining water quality and efficient wastewater treatment. However, troubleshooting common issues can be critical to ensuring optimal performance. One prevalent problem is clogging, which can occur due to excessive solids load. According to a report from the Water Environment Federation, around 30% of operational inefficiencies in drum filters stem from improper maintenance and clogging. Regularly checking and adjusting the filtration mesh size can help mitigate this issue, ensuring that only suitable solids pass through the system.

Another challenge is inconsistent flow rates, often caused by mechanical failures or wear and tear. The International Journal of Water Management indicates that maintaining consistent flow is vital; deviations can lead to subpar filtration and increased operational costs. Regular inspections and timely component replacements can significantly reduce downtime.

**Tips:** To enhance performance, implement a routine maintenance schedule. By cleaning the filter media weekly, you can prevent buildup and prolong the lifespan of the system. Additionally, consider investing in automated monitoring technologies to track flow rates and identify any irregularities promptly. This proactive approach can save both time and resources while maintaining optimal filter performance.

This chart illustrates key performance metrics for optimizing the effectiveness of rotating drum filters. The data points show typical values for flow rate, pressure drop, filtration efficiency, and maintenance frequency, helping to identify areas for potential improvement.

Investing in technology upgrades is essential for optimizing the performance of rotating drum filters, particularly in the context of increasing environmental challenges such as microplastic pollution. Recent studies highlight that microplastics significantly affect marine ecosystems, prompting a demand for advanced filtration solutions. Implementing technological enhancements such as AI-powered monitoring systems can boost filter effectiveness by enabling real-time data analysis, ultimately leading to improved filtration efficiency. Reports indicate that organizations adopting innovative filtration technologies are experiencing a transformation in operational efficacy, with some achieving up to a 30% reduction in water resource wastage.

Moreover, public-private partnerships play a crucial role in driving sustainable innovations in water treatment technologies. Collaborative efforts can enhance financing options for advanced filtration systems, making them more accessible to industries facing strict environmental regulations. By leveraging the latest technological advances, such as automated filtration systems integrated with IoT capabilities, organizations can improve their ability to combat pollution while also maximizing their investment. According to industry analyses, sustainable upgrades in water treatment facilities can yield a return on investment of up to 15%, underscoring the economic viability of such technology investments in the long run.