+86 13600513715

+86 13600513715

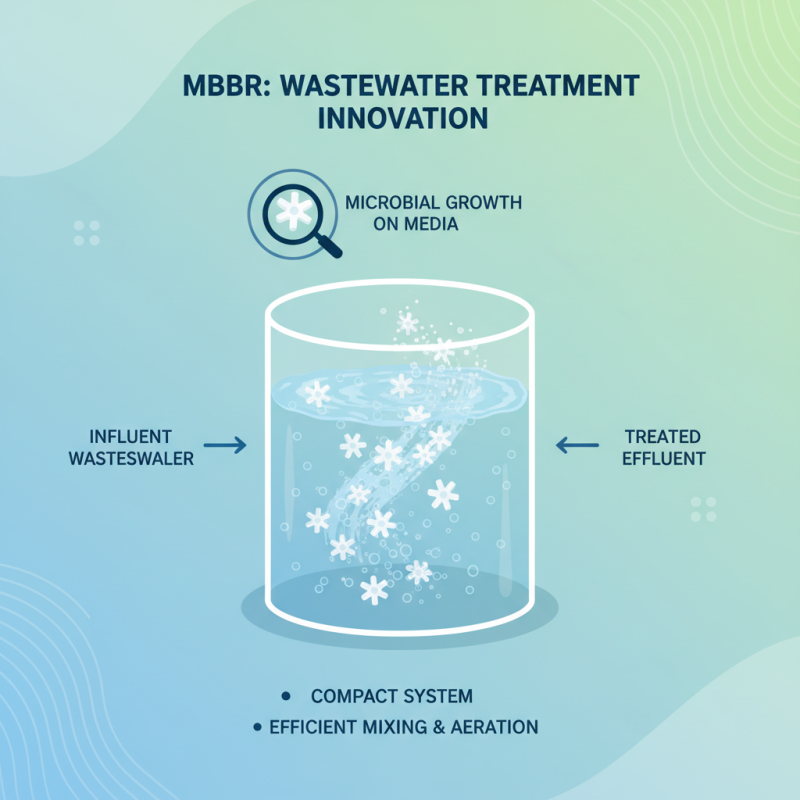

The Moving Bed Bioreactor (MBBR) is gaining attention in wastewater treatment. It uses plastic carriers to support biofilm growth. This technology enhances treatment efficiency while minimizing space requirements.

MBBR systems show promise for various industrial applications. They effectively reduce organic matter and nitrogen levels in wastewater. Many plant operators appreciate their flexibility. However, challenges remain in scaling and operational costs.

Monitoring the biofilm's health is crucial. Overgrowth can lead to poor treatment performance. Yet, the adaptable design of MBBRs offers room for improvement. This innovative approach could reshape wastewater treatment strategies globally.

Moving Bed Bioreactors (MBBRs) have gained attention in wastewater treatment due to their efficiency. They provide a compact design that requires less space than traditional treatment systems. MBBRs can lead to significant reductions in operational costs, with studies indicating a 30% decrease in energy usage compared to other methods. This efficiency can be attributed to their high biomass concentration and effective mixing.

The adaptability of MBBRs is also noteworthy. They can handle varying loads and are suitable for different types of wastewater. Reports show that MBBRs can achieve removal rates of over 90% for organic matter. However, challenges remain, such as biofilm sloughing and the maintenance of optimal conditions for microbial activity. These issues need thoughtful monitoring.

Additionally, the startup period for MBBRs may take longer than expected. It can take weeks for the biofilm to develop properly. Depending on operational parameters, the system might not always perform at its highest efficiency early on. Operators must remain vigilant during this phase to avoid potential setbacks in treatment performance. Overall, while moving bed bioreactors offer numerous advantages, they also require careful consideration and management.

| Advantage | Description | Efficiency | Maintenance |

|---|---|---|---|

| High Treatment Efficiency | Moving bed bioreactors utilize biofilm growth on moving media, leading to higher removal rates of contaminants. | >95% BOD removal | Requires periodic media replacement. |

| Space Efficiency | Compact design requires less area compared to traditional systems. | Smaller footprint | Minimal land requirement. |

| Operational Flexibility | Can be adapted for various types of wastewater with different flow rates. | Handles fluctuations well | Adjustable operating parameters. |

| Reduced Sludge Production | Lower sludge generation due to more efficient enzymatic activity. | Reduced sludge volume | Less frequent disposal needed. |

| Improved Process Stability | Resilience to shock loads and varying conditions increases operational reliability. | Consistent output quality | Low risk of process upset. |

Moving bed bioreactors (MBBRs) offer innovative solutions for wastewater treatment. They outperform traditional methods such as activated sludge systems. In many studies, MBBRs have demonstrated superior removal rates for pollutants, reaching 90% efficiency for BOD and COD. This is a significant improvement over the typical 70-80% efficiency seen in conventional systems.

MBBRs utilize biofilm technology, which enhances microbial growth. This allows for higher concentrations of biomass in a smaller footprint. Traditional systems often require larger tanks and more energy for aeration. A report by the Water Environment Federation indicates a potential energy saving of 30% with MBBR systems. This can contribute to lower operational costs.

Tips: When considering wastewater treatment options, evaluate the space available. MBBRs can fit in tight spaces where traditional tanks may not. Additionally, keep in mind that while MBBRs can be efficient, they require careful monitoring of biofilm health. Overgrowth or underperformance can lead to inconsistent results. Regular maintenance and adjustments are key to maximizing their benefits.

Moving Bed Bioreactors (MBBRs) are gaining popularity in wastewater treatment. They provide an efficient way to enhance biological processes. In MBBRs, small plastic media move freely in the tank, offering a larger surface area for microbial growth. This allows for the treatment of wastewater while maintaining a compact system. The moving media ensures effective mixing, which is essential for aeration and nutrient distribution.

There are several operational mechanics that make MBBRs effective. The moving bed creates a dynamic environment where microorganisms attach to the media. This leads to higher biomass concentrations without clogging issues. The design minimizes sedimentation and keeps particles suspended. Additionally, the gentle movement of the media prevents the formation of dead zones, enhancing treatment efficiency.

Tip: Regularly monitor the media for wear and tear. Over time, media can degrade and affect performance. Keep your system well-maintained.

Operational challenges can occur with MBBRs. For example, ensuring the right balance of flow and biomass retention can be tricky. If too much media is added, it may lead to inadequate treatment. Adjusting air supply and monitoring microbial health is crucial.

Tip: Conduct routine inspections of your system. Identifying issues early can prevent bigger problems down the line. Be mindful of your operational parameters for optimal performance.

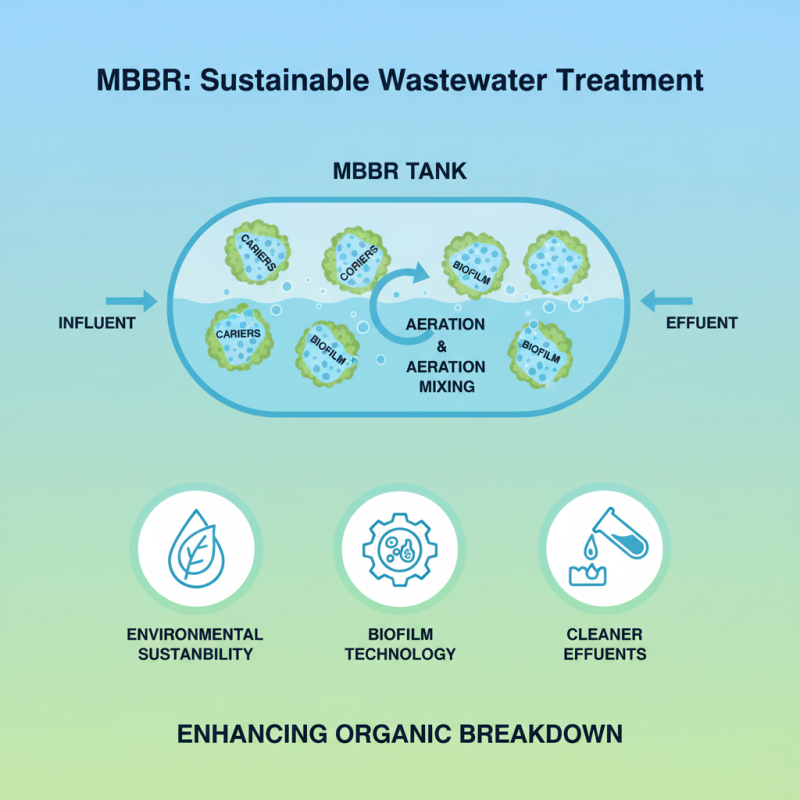

Moving Bed Bioreactors (MBBRs) are gaining attention for their effectiveness in wastewater treatment. These systems provide significant contributions to environmental sustainability. By utilizing biofilm technology, they enhance the breakdown of organic materials. This process results in cleaner effluents released into water bodies.

Resource recovery is another vital aspect of MBBRs. These reactors not only treat wastewater but also help in recovering valuable resources. For instance, they can facilitate nutrient recovery, particularly nitrogen and phosphorus. This capability is essential in combatting nutrient pollution in aquatic ecosystems. With rising concerns about water quality, finding sustainable solutions becomes critical.

However, challenges remain. The initial setup costs can be high. Moreover, the efficiency of MBBRs can vary based on operational conditions. Achieving uniform biofilm development requires careful monitoring. This variability leads to questions about long-term performance. Addressing these challenges is necessary for broader adoption of MBBRs. Ultimately, the potential for sustainability and resource recovery makes them a worthy option for the future.

Moving Bed Bioreactors (MBBRs) offer flexibility in wastewater treatment. They support diverse applications, making them a popular choice. For instance, an MBBR can treat municipal wastewater effectively. In one case study, a city improved its effluent quality significantly using this technology. Additionally, an industrial park faced challenges with high nutrient concentrations. After implementing an MBBR, they observed a remarkable reduction in nitrates and phosphates.

Tips: Monitor the flow rate regularly. This information helps optimize the process.

Another compelling application involves food processing plants. These facilities generate large volumes of organic waste. An MBBR can handle this while reducing sludge production. One plant reported a 30% decrease in activated sludge build-up after its implementation. However, some operators struggled with fouling issues. Regular maintenance is crucial to avoid disruptions.

Tips: Always inspect the media. This can prevent potential blockages.

MBBR systems are also beneficial for remote areas. They are compact and easy to install. In such cases, operators must ensure proper aeration. A case study revealed that improper aeration led to poor treatment outcomes. Hence, adjustments might be necessary. Operators should be vigilant and adapt as required.

This chart illustrates the removal efficiencies of various pollutants using Moving Bed Bioreactors (MBBRs) in wastewater treatment. The MBBR technology is known for its effectiveness in reducing Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), and Total Suspended Solids (TSS).