+86 13600513715

+86 13600513715

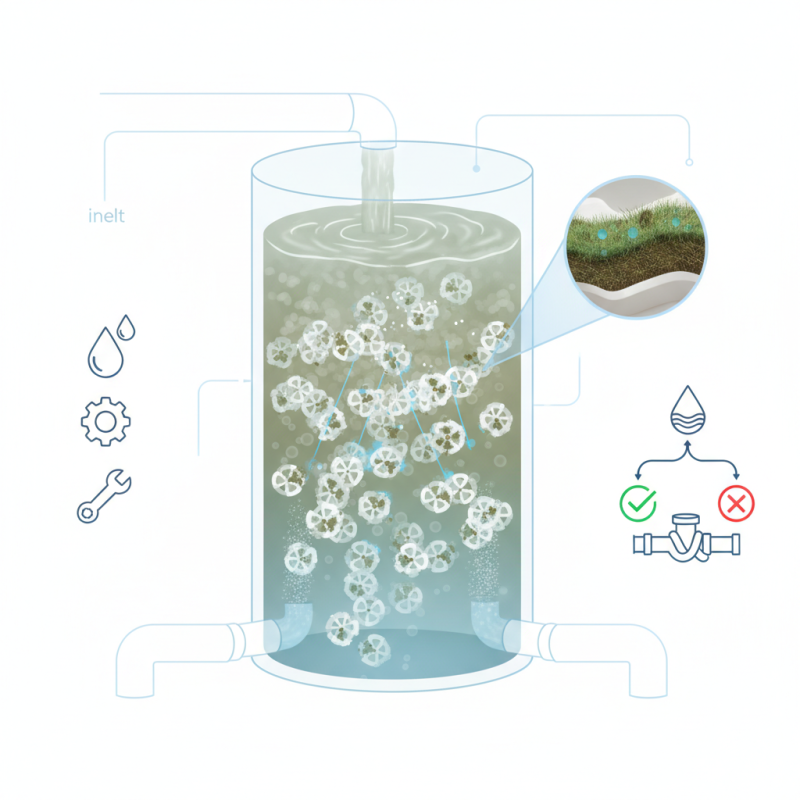

The Mbbr Filter is an innovative solution in wastewater treatment. It combines physical, biological, and chemical processes. This method uses plastic media to enhance microbial growth. As wastewater flows through the filter, it encounters these specialized media. They create a surface for bacteria to thrive.

The efficiency of the Mbbr Filter lies in its design. It allows for higher contact between wastewater and microorganisms. This interaction accelerates the breakdown of organic matter. However, the technology is not without challenges. Proper maintenance is crucial for its effectiveness. Sometimes, clogging can occur, which may hinder performance.

Yet, the potential benefits are promising. Mbbr Filters can significantly improve water quality. They offer flexibility and adaptability for various applications. Understanding how this filter works could lead to better wastewater treatment solutions. Exploring its mechanisms can reveal both strengths and weaknesses in design. Being aware of these factors is essential for optimal use.

MBBR technology is an innovative method used in water treatment. It stands for Moving Bed Biofilm Reactor. This technology employs special plastic carriers to create a biofilm that treats wastewater. The design allows for efficient treatment while minimizing space requirements.

In MBBR systems, wastewater flows through a tank filled with these carriers. The biofilm grows on the surface of the carriers. This setup promotes the growth of microorganisms, which break down contaminants in the water. The process creates a healthy ecosystem for bacteria to thrive and help in purification.

Tips: Maintain an optimal temperature in your MBBR system. Elevated temperatures can benefit bacterial activity. However, too much heat can also harm unwanted microorganisms. Check the flow rate regularly. An uneven flow may lead to inefficient treatment.

While MBBR is effective, some challenges exist. The biofilm can become too thick, leading to a decrease in treatment efficiency. Regular monitoring is essential to prevent this issue, as thin biofilms often perform better. Finding the right balance in biofilm thickness is vital for consistent performance.

Keep in mind that not every wastewater stream is suitable for MBBR technology. It's essential to assess the characteristics of the inflow before implementation. This step is crucial for achieving optimal results.

| Parameter | Description | Value/Range |

|---|---|---|

| Media Type | Type of carrier media used in the MBBR process. | Polyethylene |

| Carrier Size | Diameter of the biofilm carriers. | 10-15 mm |

| Operating Temperature | Optimal range for biological activity. | 10-30 °C |

| Hydraulic Retention Time (HRT) | Time water remains in the reactor. | 2-24 hours |

| Organic Loading Rate (OLR) | Amount of organic matter entering the system. | 0.5-5 kg COD/m³/d |

| Removal Efficiency | Typical removal rates for BOD and TSS. | 75-90% BOD, 70-85% TSS |

| Application | Typical usage scenarios for MBBR filters. | Municipal wastewater treatment, industrial effluents |

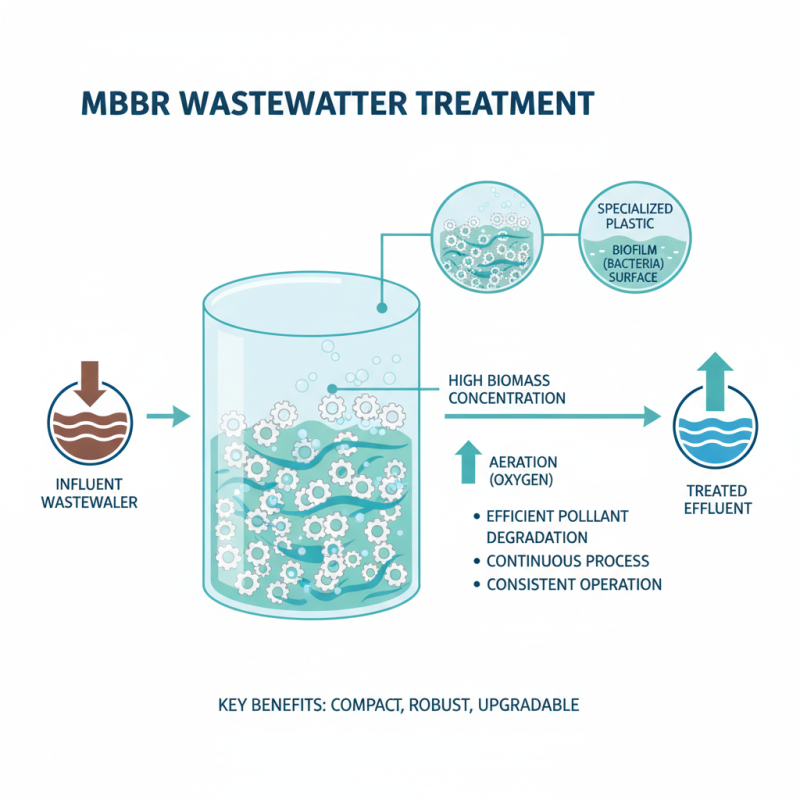

MBBR (Moving Bed Biofilm Reactor) filters are essential in modern wastewater treatment. They use specific design components to achieve effective results. A typical MBBR system consists of a reactor tank, biofilm carriers, and aeration mechanisms. These carriers support microbial growth, creating biofilms that degrade pollutants.

The reactor tank is the heart of the MBBR system. It allows for constant movement of the biofilm carriers. This movement enhances contact between the microorganisms and wastewater. Aeration systems maintain dissolved oxygen levels, crucial for aerobic bacteria. Reports indicate that MBBR systems can achieve over 90% removal of biochemical oxygen demand (BOD) from wastewater, showcasing their efficiency.

Despite their advantages, challenges remain. Biofilm thickness can vary, impacting treatment performance. Uneven aeration can lead to insufficient oxygen in certain areas. Some studies suggest that biofilm carriers may become clogged, reducing their effectiveness. Regular monitoring is necessary, as inconsistent operation can hinder overall system efficiency. It's important to address these issues to optimize MBBR performance.

MBBR filters utilize a unique approach to wastewater treatment. They combine fixed film and suspended growth processes. In this system, plastic carriers are used to support microbial growth. These carriers move freely in the reactor, maximizing contact with wastewater. This leads to more efficient breakdown of pollutants.

During operation, wastewater enters the reactor and comes into contact with the biofilm on the carriers. Microorganisms digest organic material in the water. However, managing the balance of nutrients can be challenging. If the nutrient levels are off, the efficiency drops. Careful monitoring is crucial.

As wastewater flows through, the treated effluent is separated from the carriers. Some remain in the system to maintain a healthy microbial population. Others are periodically removed for maintenance. This can be a complex process. Operators need to ensure proper conditions for optimal performance. It's not always easy, but understanding the system helps achieve better results.

In recent years, the Moving Bed Biofilm Reactor (MBBR) has gained attention as an innovative wastewater treatment method. This technology uses biofilm-coated media that moves freely within the reactor. It offers significant advantages compared to traditional treatment methods like Activated Sludge. For example, the MBBR can reduce the footprint of a treatment plant by up to 50%, according to industry data.

In contrast, traditional methods often require more space and extensive infrastructure. MBBRs can efficiently treat high fluctuations in wastewater flow and load. Some studies suggest that MBBRs can achieve up to 90% removal efficiency for organic matter, outperforming conventional systems in many cases. However, the initial investment for MBBRs can be higher, and operation requires careful management of biofilm growth.

What’s particularly interesting is that while MBBRs show promising removal rates and flexibility, they are not without challenges. Operators may struggle with biofilm detachment and maintenance costs. Reports indicate that operators still need to assess the longevity of media, as wear and tear can affect performance. This highlights the need for ongoing research and adaptive management in MBBR usage. There’s potential, but caution is needed to ensure long-term efficiency.

MBBR systems stand out in wastewater treatment for their efficiency and effectiveness. They utilize specialized plastic media that create a surface for bacteria to thrive. This design enables a higher concentration of biomass, leading to better degradation of pollutants. The process is continuous, promoting consistent operation.

One performance metric to consider is the system's removal efficiency. MBBR systems can achieve high rates of organic material removal. However, they can struggle with variations in wastewater characteristics. Changes can affect microbial activity. Operators must monitor conditions closely to maintain optimal performance.

Effectiveness also hinges on proper design and maintenance. The right balance of flow rate and media surface area is crucial. If miscalculated, some areas may receive too little treatment. Regular assessments and potential adjustments are necessary, reflecting the ongoing need for vigilance in system performance.