+86 13600513715

+86 13600513715

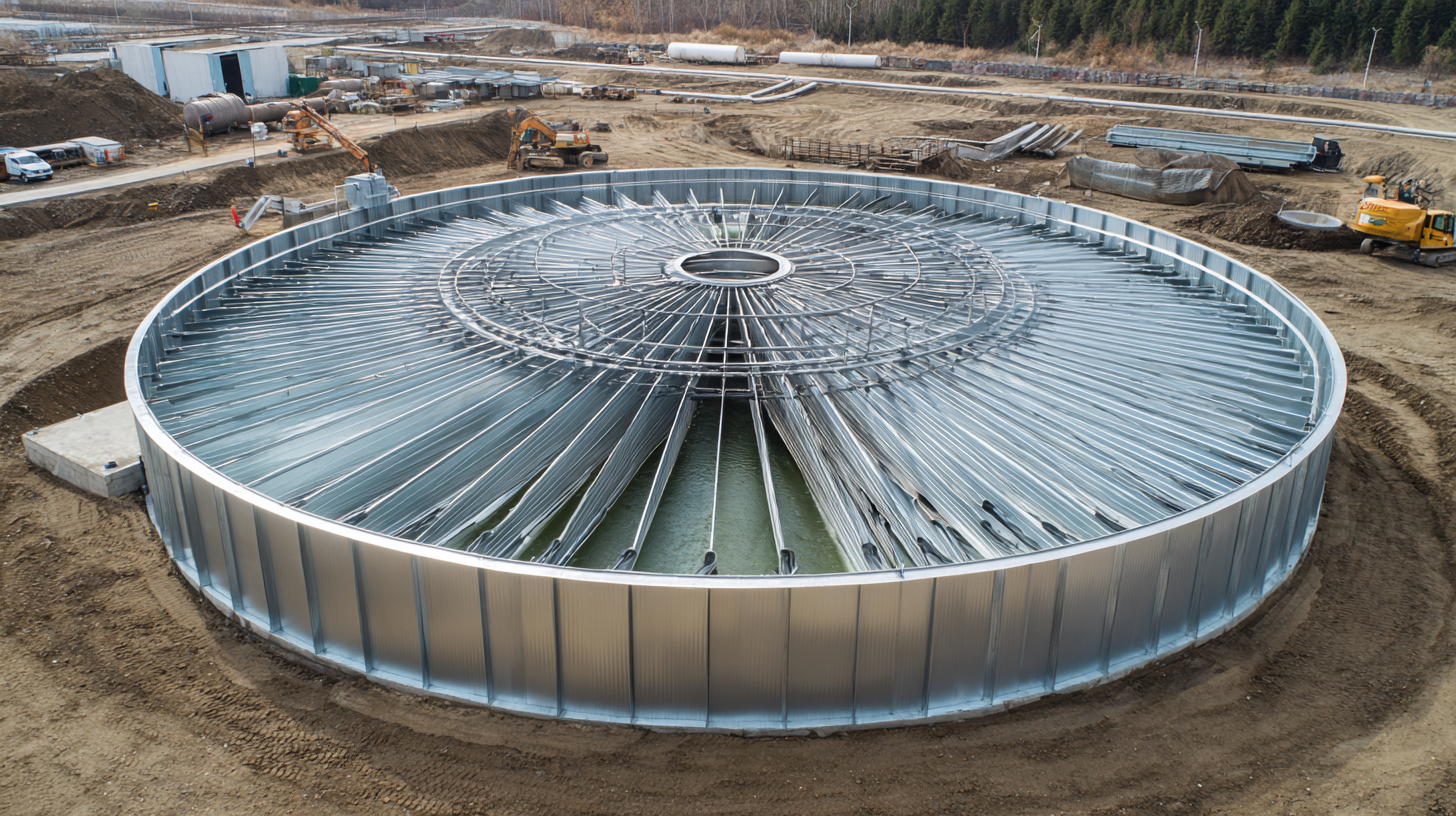

In the quest for enhanced aeration efficiency, the integration of innovative solutions such as the Disc Diffuser Aerator has emerged as a critical focus for wastewater treatment facilities worldwide. According to a report by the Water Environment Federation, optimizing aeration processes can lead to energy savings of up to 30%, significantly affecting operational costs and environmental sustainability. Furthermore, the utilization of Disc Diffuser Aerators allows for improved oxygen transfer efficiency, with studies indicating that these systems can achieve oxygen transfer rates exceeding 10 kg O2/kWh—far superior to traditional aeration methods. As water treatment regulations become increasingly stringent, the demand for efficient and reliable aeration solutions only continues to grow, making the advancement of Disc Diffuser Aerators pivotal in addressing both operational performance and ecological responsibility in the industry.

Aeration is a critical component of water treatment processes, playing a pivotal role in enhancing the efficiency of biological treatment systems. It significantly improves the dissolution of oxygen in water, thus supporting aerobic microorganisms that break down organic pollutants. According to the Water Environment Federation, effective aeration can increase the removal of biochemical oxygen demand (BOD) by up to 90%, making it essential for maintaining water quality and meeting regulatory standards.

Disc diffuser aerators have emerged as a superior option compared to traditional methods for enhancing aeration efficiency in wastewater treatment systems. Unlike conventional methods that often rely on coarse bubbles for oxygen transfer, disc diffusers utilize fine bubble technology, which creates a larger surface area for gas exchange. Recent studies indicate that fine bubble diffusers can increase oxygen transfer efficiency by up to 40% compared to coarser alternatives, implying that less energy is consumed for the same aeration needs.

Furthermore, the membrane bubble aeration units demonstrate significant enhancements in both lab-scale and full-scale system performances. Research highlights that the low solubility of oxygen in water presents a challenge for effective gas transfer at the gas/liquid interface. However, innovations in disc diffuser design, such as engineered membrane materials and optimized bubble sizes, can mitigate this limitation. This not only improves the operational efficiency of wastewater treatment facilities but also contributes to reduced operational costs and lower energy consumption—critical factors in a world increasingly focused on sustainability and efficiency in water management practices.

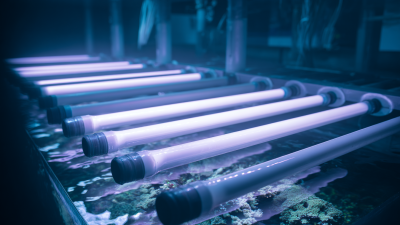

Innovative disc diffuser aerator solutions are at the forefront of enhancing aeration efficiency in various water treatment applications. One of the key design features is the use of advanced materials that maximize durability while minimizing fouling. By utilizing robust, corrosion-resistant materials, these diffusers maintain their performance over extended periods, reducing the need for frequent maintenance and replacements.

Another significant design aspect is the strategic placement and configuration of the diffuser discs. This arrangement ensures optimal air distribution and enhances oxygen transfer efficiency. The design allows for finer, more uniform bubbles to be produced, which not only improves the overall oxygen transfer rate but also promotes better mixing within the water column. Additionally, many innovative designs incorporate modular features, making installation and adjustments easier, ultimately leading to lower operational costs and better overall performance.

To optimize aeration efficiency with disc diffusers, it is essential to understand the key factors that influence their performance. First, selecting the right type of disc diffuser tailored to the specific needs of the wastewater treatment process can greatly enhance oxygen transfer rates. Utilizing high-quality materials and innovative designs can increase durability and reduce maintenance requirements, allowing for a more efficient operational lifespan.

Another strategy is to regularly monitor and adjust the aeration system. Implementing advanced monitoring technologies can provide real-time data on dissolved oxygen levels and ensure that aeration is optimized according to varying load conditions. Furthermore, periodic cleaning and maintenance of the diffusers help prevent clogging, which can diminish efficiency and lead to increased energy consumption. By focusing on these strategies, facilities can achieve significant improvements in aeration efficiency, resulting in better treatment outcomes and lower operational costs.

Innovative disc diffuser aerators are transforming the landscape of wastewater treatment and aquaculture with their ability to enhance aeration efficiency. In real-world applications, such as municipal wastewater treatment plants, these systems have demonstrated remarkable effectiveness in improving oxygen transfer rates. A notable case study from a facility in California illustrated a 30% reduction in energy consumption after implementing disc diffusers, which not only optimized the aeration process but also resulted in significant cost savings over time.

In aquaculture, the integration of innovative disc diffuser aerator solutions has shown to bolster fish health and growth rates. A farm in Asia reported a 20% increase in fish yield following the adoption of these systems. The uniform distribution of micro-bubbles created by disc diffusers promotes better oxygenation throughout the water column, leading to improved water quality and a healthier aquatic environment. As these case studies exemplify, the implementation of advanced aeration technologies is reshaping operational efficiency and sustainability across various sectors.