+86 13600513715

+86 13600513715

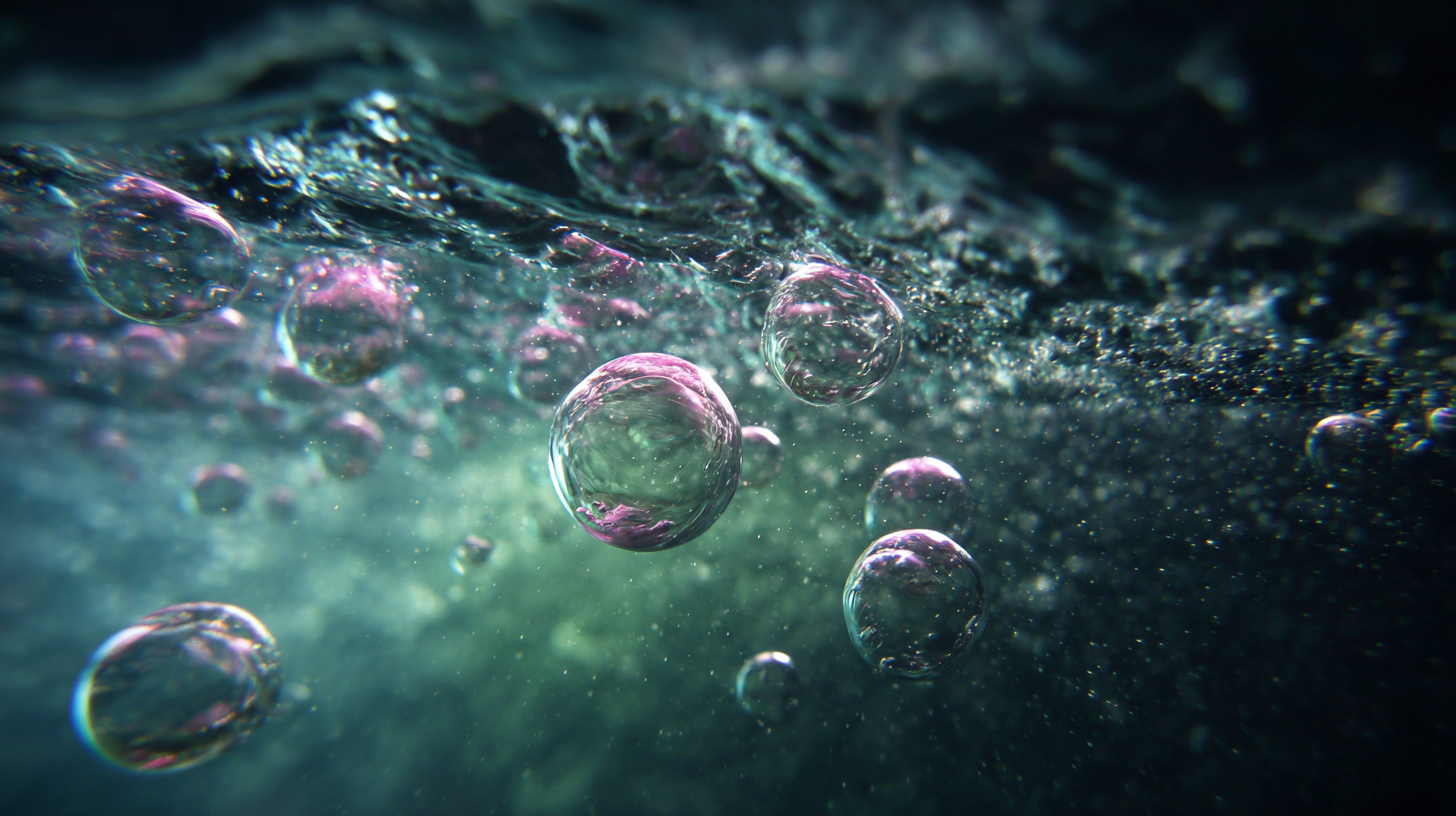

In the world of wastewater treatment and aquaculture, the choice of aeration systems is critical for ensuring optimal performance and efficiency. Among various aeration technologies, the Fine Bubble Tube Diffuser has gained significant attention due to its ability to maximize oxygen transfer efficiency by generating smaller bubbles that dissolve more effectively in water. According to the Environmental Protection Agency (EPA), the efficiency of aeration systems can limit energy consumption by up to 30% when equipped with high-performance diffusers. As the demand for sustainable and cost-effective solutions rises, understanding the essential factors in selecting the right Fine Bubble Tube Diffuser becomes paramount for operators aiming to enhance system efficacy while reducing operational costs. In this blog, we present five essential tips that will guide you through the selection process, ensuring you make an informed decision that meets your specific needs.

Understanding Fine Bubble Tube Diffusers: What You Need to Know

Fine bubble tube diffusers have become a critical component in wastewater treatment processes and aquaculture due to their efficiency in oxygen transfer. According to the Water Environment Federation's 2021 report, fine bubble technologies can achieve oxygen transfer efficiencies of over 80%, significantly higher than traditional coarse bubble systems, which typically range around 30-50%. The small size of fine bubbles increases the surface area for gas exchange, allowing for better oxygenation, which is essential for aerobic microbial activity in wastewater treatment.

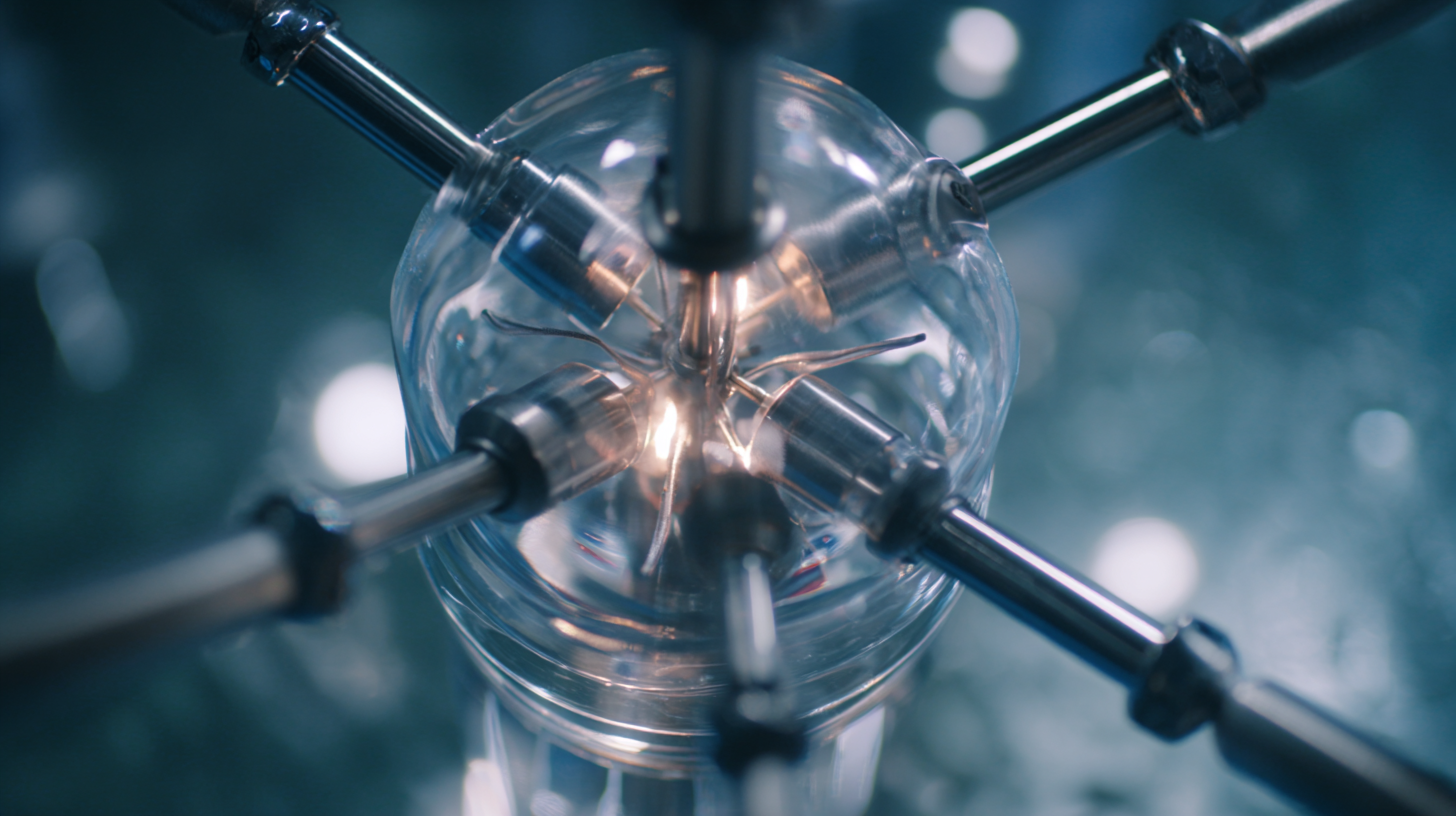

When selecting a fine bubble tube diffuser, it’s crucial to consider materials and design to ensure optimal performance and durability. Reports indicate that diffusers constructed from materials such as EPDM or silicone can enhance lifespan and operational efficiency, with some models lasting over 15 years under optimal conditions. Furthermore, understanding the application-specific requirements, such as the depth of installation and flow rates, can greatly impact the overall effectiveness. The American Society of Civil Engineers emphasizes the importance of matching diffuser specifications with the operational parameters of the treatment facility to maximize aeration efficiency and reduce energy costs.

When selecting a fine bubble tube diffuser, it’s essential to consider several key factors that can significantly impact its performance. One of the main aspects is the material and construction of the diffuser. Look for durable and corrosion-resistant materials that can withstand the harsh conditions typically found in aquaculture or wastewater treatment applications. A well-built diffuser will ensure longevity and efficiency in gas exchange.

Another critical factor to keep in mind is the bubble size and distribution. Different applications may require specific bubble sizes to achieve optimal performance. Fine bubbles tend to increase surface area and improve oxygen transfer rates, but the ideal size can depend on the type of system you are operating. Conducting tests with various diffusers can help identify the best option for your needs.

Lastly, consider the maintenance and cleaning requirements of the diffuser. A design that allows for easy inspection and cleaning can save time and resources in the long run. Regular maintenance will ensure that the diffuser continues to operate effectively, enhancing the overall efficiency of your system. Making informed choices based on these tips can lead to more successful outcomes in your applications.

| Tip | Description | Considerations |

|---|---|---|

| 1. Check the Bubble Size | Choose a diffuser that produces the right bubble size for your application. | Smaller bubbles offer better oxygen transfer but require more maintenance. |

| 2. Material Quality | Consider diffusers made from durable materials that resist fouling. | Silicone and EPDM are popular; they can affect longevity. |

| 3. Flow Rate Compatibility | Ensure the diffuser suits the flow rate of your aeration system. | Too high or too low flow can affect performance. |

| 4. Maintenance and Cleaning | Select a diffuser that is easy to clean and maintain. | Regular maintenance ensures optimal performance and longevity. |

| 5. Cost vs. Performance | Evaluate the cost in relation to the performance benefits. | A higher initial investment may lead to savings in energy and maintenance. |

When selecting a fine bubble tube diffuser, the material used in its construction can significantly impact efficiency and longevity. Generally, diffusers are made from materials like EPDM, silicone, and ceramic. EPDM diffusers are known for their durability and resistance to harsh environments, making them ideal for industrial applications. They can effectively handle varying water chemistry, ensuring optimal performance over time. On the other hand, silicone diffusers offer excellent flexibility and are often used in aquaculture and aquarium settings, where gentle aeration is required to protect delicate aquatic life.

Ceramic diffusers are another popular choice, particularly for their fine bubble production and ease of cleaning. They tend to provide a longer lifespan and a higher oxygen transfer rate, making them suitable for wastewater treatment plants where efficiency is paramount. However, the initial investment can be higher compared to other materials. It's crucial to consider the specific needs of your application, including water conditions, required airflow, and the budget. By comparing these materials thoughtfully, you can make a more informed decision that optimally meets your aeration needs.

When it comes to selecting the right fine bubble tube diffuser, evaluating its performance is crucial, especially in terms of efficiency and flow rates. One of the primary aspects to consider is the oxygen transfer efficiency (OTE). This metric tells you how well the diffuser can convert the air supplied into dissolved oxygen in the water. Higher OTE values indicate more effective diffusion, making it an essential parameter for any aquatic system, whether you're managing a large-scale aquaculture operation or an ornamental pond.

Another important factor is the flow rate. This determines how much air can be introduced into the water at a time, impacting the overall performance of the diffuser. A well-chosen flow rate should match the specific needs of your system, as too high a flow can lead to excessive turbulence, while too low a flow might not meet oxygen demands. To accurately assess these parameters, it’s advisable to consult product specifications and perform field tests where possible, ensuring that the selected diffuser delivers optimal performance tailored to your specific requirements.

When investing in a fine bubble tube diffuser, proper maintenance is crucial for ensuring its longevity and optimal performance. According to the Water Environment Federation, regular maintenance can reduce the operational lifespan of a diffuser by up to 30% if neglected. Therefore, routine inspections should be conducted to check for clogging or scaling, which can significantly impede airflow and reduce efficiency. Utilize a soft brush or a gentle cleaning technique to remove debris without damaging the diffuser.

Additionally, maintaining appropriate water quality is essential. A report by the International Water Association indicates that fine bubble diffusers perform best in conditions where total dissolved solids (TDS) and alkalinity are monitored. High levels of TDS can lead to faster fouling of the diffuser membranes. By routinely testing water parameters and ensuring chemical treatments are applied when necessary, operators can extend the diffuser’s lifespan and enhance its efficiency, maintaining a consistent oxygen transfer rate.