+86 13600513715

+86 13600513715

When selecting a submersible mixer, clarity and expertise are essential. According to Dr. Emily Carter, a noted expert in aquatic engineering, "The right submersible mixer can transform a water treatment process." Her insight emphasizes the importance of making a well-informed choice.

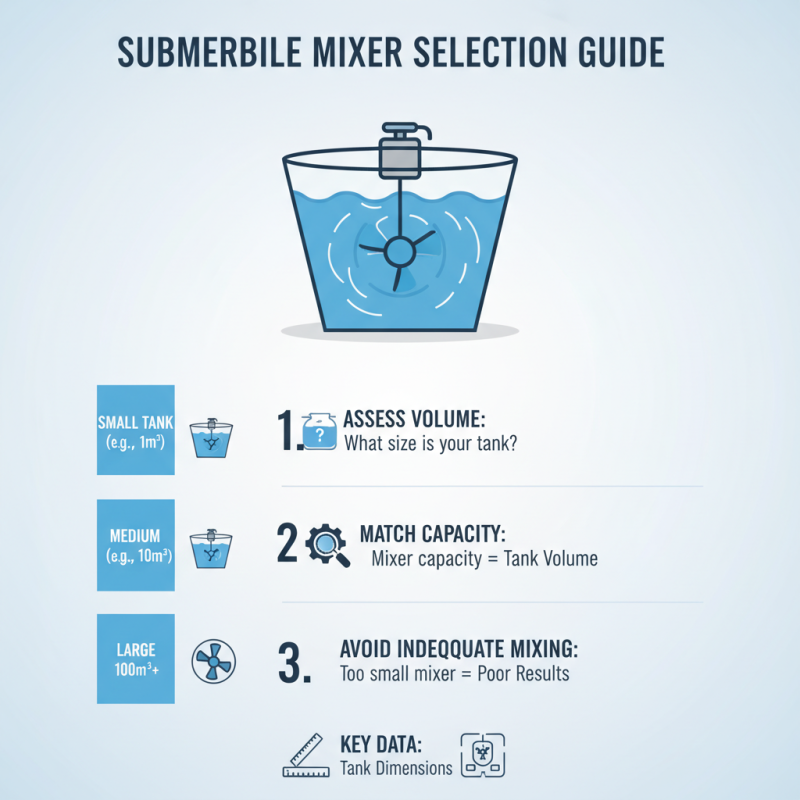

The submersible mixer must fit specific needs. Consider factors such as tank size and water conditions. A wrong selection could lead to inefficiencies, increased costs, and inadequate mixing. It's critical to assess the application's requirements thoroughly. Each project has unique demands that must not be overlooked.

Understanding these elements helps mitigate risks. While it's tempting to opt for the most advanced model, simplicity often proves beneficial. Sometimes, a basic mixer outperforms a high-end version, creating a need for reflection. Striking the right balance between technology and practicality is key in navigating choices in the submersible mixer market.

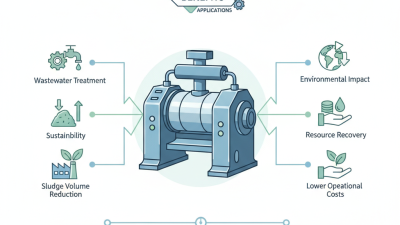

Submersible mixers are vital in various industries, including wastewater treatment and food processing. They help create a uniform mixture of fluids, aiding in efficient chemical reactions. There are different types of mixers, such as hydraulic and electric, each with specific applications. According to a 2022 market report, the global submersible mixer market is expected to grow by 5.4% annually. This growth highlights the increasing demand for these devices.

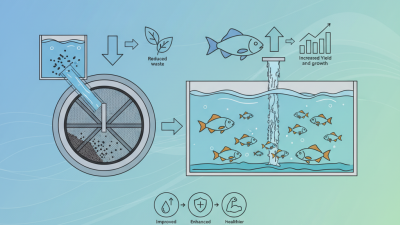

Hydraulic mixers are often used in large tanks. They can handle thick sludge effectively. Electric submersible mixers are more common in compact applications like aquaculture. While choosing a mixer, consider the viscosity of the materials you will mix. Different mixers perform better with different fluid types. A mismatch can reduce efficiency.

Maintenance is crucial but often overlooked. Regular checks can prevent breakdowns and prolong mixer life. The right mixer can also minimize energy consumption. According to a 2023 study, energy-efficient models can save up to 30% in operating costs. Choosing the wrong type, however, can lead to higher expenses because of increased wear and tear. Be cautious and weigh your options carefully.

| Type of Mixer | Application | Motor Power (HP) | Speed (RPM) | Max Depth (m) |

|---|---|---|---|---|

| Inline Submersible Mixer | Wastewater Treatment | 5 | 1500 | 10 |

| Propeller Mixer | Sludge Mixing | 10 | 1200 | 8 |

| Jet Mixer | Biogas Plants | 7.5 | 1600 | 12 |

| Submersible Agitator | Chemical Mixing | 3 | 1800 | 15 |

| Dual Mixer | Pond Aeration | 5 | 1400 | 9 |

Choosing the right submersible mixer can be challenging. There are several key factors to consider. The type of liquid you are mixing greatly affects your selection. For instance, thick sludge requires a powerful mixer. In contrast, thin liquids may not need as much force. Understanding the viscosity of your fluid is essential. Reports indicate that nearly 30% of mixer failures stem from improper design choices.

Another critical aspect is the mixing depth. Some applications need deeper mixing capabilities. Therefore, checking your mixer’s specifications is vital. Proper depth ensures efficient mixing, reducing energy consumption. A poorly chosen mixer may lead to uneven distribution. This can affect overall performance and increase operational costs.

**Tip:** Always review user feedback when selecting a mixer. Practical insights from professionals can help you avoid common pitfalls.

Furthermore, consider the environment where the mixer will operate. Conditions like temperature and chemical exposure can impact performance. Make sure the mixer materials are compatible with your fluids. This minimizes corrosion risks.

**Tip:** Perform a cost-benefit analysis. Weigh initial investment against long-term maintenance costs. This helps in making an informed decision.

When selecting a submersible mixer, it's crucial to assess your mixing requirements. The first thing to consider is volume. Define the size of the tank where the mixer will operate. A small tank needs a different mixer than a large one. The mixer’s capacity should match the volume to ensure effective mixing. If the volume is too large, mixing may be inadequate. Data on tank dimensions can help in making the right choice.

Viscosity is another key factor. Different materials, like sludge or thick liquids, require varying levels of mixing power. A high-viscosity substance may need a more powerful mixer to achieve a homogenous mix. There are times when the mixing action may not disperse the material evenly. This can lead to settling or clumping. Experimenting with different speeds and designs can yield better results.

Don't forget the specific application. Each industry has unique requirements. Some mixers work better in certain environments than others. You may find some models work well in laboratory settings but struggle in industrial applications. Assessing the environment and potential challenges will refine your selection. Reflect on past experiences. Have you faced issues with previous mixers? Learning from them can guide your next purchase.

Choosing the right submersible mixer involves understanding energy efficiency and maintenance needs. Energy efficiency is critical. According to a report by the U.S. Department of Energy, energy consumption in treatment facilities can account for up to 30% of operational costs. Selecting a mixer with a high-efficiency motor can significantly reduce this expense. Look for models with variable frequency drives, which adapt to flow rates and save energy when demand is low.

Maintenance is another key factor. Operators should consider the ease of serviceability. A study from the Water Environment Federation indicates that poorly maintained mixers can result in up to 20% productivity loss. Regular inspections and accessible parts can minimize downtime. Also, remember to reflect on the environment where the mixer will operate. Corrosive materials may increase wear and require more frequent maintenance checks. An effective mixer should balance durability and efficiency to meet specific operational needs.

When budgeting for a submersible mixer, it’s vital to consider initial costs versus long-term savings. The price of a submersible mixer can range from $2,000 to $10,000 depending on size, capacity, and features. According to industry reports, energy-efficient mixers can save facilities up to 30% on operational costs. This highlights the importance of choosing the right mixer, as a higher upfront cost may lead to significant savings over time.

Maintenance costs also play a crucial role. Many facilities overlook these expenses. Routine maintenance can average around $500 annually. In contrast, neglect can lead to costly repairs and downtime. A study shows that improper mixer usage can increase energy costs by 15%. Understanding these aspects is vital for effective budgeting.

Considering the lifetime of the mixer is another factor. High-quality mixers can last over a decade with proper care. However, choosing cheaper options might result in frequent replacements. This cycle can inflate overall costs. A well-thought-out investment now can lead to fewer headaches and better efficiency later.