+86 13600513715

+86 13600513715

Choosing the right Sludge Press Machine is crucial for various industries. Wastewater treatment plants, for example, require efficient dewatering solutions. According to a report by MarketsandMarkets, the global sludge dewatering equipment market is projected to reach nearly $3.5 billion by 2025. This growth underscores the increasing need for effective sludge management.

A Sludge Press Machine can significantly impact operational efficiency and costs. The right machine minimizes residual moisture, leading to lower disposal costs. However, making the wrong choice can result in higher operational costs and increased environmental impact. Data from the Environmental Protection Agency shows that improper sludge handling can lead to regulatory penalties and potential legal issues.

Consider performance, size, and maintenance when selecting a Sludge Press Machine. Each operation has unique needs, and evaluating those factors is essential. It’s not just about the initial purchase. Long-term costs, durability, and flexibility also matter. Rushing this decision may lead to regret down the line. Conduct thorough research and consult with experts in the field for the best outcomes.

When considering sludge press machines, it's vital to understand the types available. There are various models, each with unique features. Plate and frame presses offer high filtration efficiency. They use plates to create chambers. With this design, they can handle thick sludges well.

Belt presses are another option. They are more continuous in operation. This makes them suitable for larger volumes of sludge. However, the quality of dewatering may not match that of plate presses. Each type has its pros and cons.

Choosing the right one can be tricky. Consider the specific needs of your project. Think about the volume of sludge you need to process. Understand the characteristics of the sludge itself. Sometimes, what seems efficient may not be practical. Reflection on these factors is essential before making a decision.

When choosing a sludge press machine, understanding your specific sludge characteristics is essential. Sludge composition varies widely. It can contain various solids, oils, and water content. According to the Water Environment Federation, sludge can have a solids content range between 0.5% and 5%, impacting the dewatering process significantly. This variability demands a tailored approach to machinery selection.

Moisture content is another factor to consider. High moisture content can lead to increased operating costs. Machines may need to run longer to achieve desired dryness levels. Research indicates that achieving less than 80% moisture in the final product is often necessary for effective disposal or reuse. Evaluate the type of sludge and any unique properties it may have, such as viscosity or chemical composition.

Consider the operational environment too. A machine suitable for one setting may not work well in another. Space constraints can also limit your options. Often, users must balance performance and footprint. An article by the Journal of Environmental Engineering noted that inadequate space can lead to poor access for maintenance. Always assess how your specific needs align with the machinery available in the market.

| Sludge Characteristic | Recommended Press Type | Ideal Dewatering Efficiency (%) | Typical Applications |

|---|---|---|---|

| Organic Waste | Belt Filter Press | 85-90 | Food Processing, Agriculture |

| Municipal Sludge | Rotary Screw Press | 90-95 | Wastewater Treatment |

| Industrial Sludge | Plate and Frame Press | 80-85 | Chemical Industry, Pulp & Paper |

| Dairy Waste | Hydraulic Press | 90-92 | Food Processing, Dairy Production |

When selecting a sludge press machine, understanding the press size and capacity is crucial. The ideal size directly correlates to the volume of sludge produced by your operation. According to industry reports, a facility generating 10 tons of sludge per day requires a press with a capacity of at least 1.5 cubic meters per hour. It’s vital to have an accurate estimate of sludge generation.

Another factor to consider is the concentration of solids in the sludge. A higher solid content may necessitate a larger press size to achieve optimal dewatering. Studies show that presses can handle varying concentrations efficiently, but exceeding capacity can lead to poor performance. This inconsistency can result in unnecessarily prolonged processing times and increased operational costs.

Moreover, environmental conditions and space limitations could impact equipment selection. An oversized press takes up valuable space and might require more energy. Miscalculating needs can disrupt workflow, causing frustrations. Regular assessments of sludge characteristics and adjusting the press accordingly can prevent such issues. It's an ongoing process that demands attention.

When selecting a sludge press, energy efficiency becomes crucial. High energy consumption can quickly increase operational costs. Therefore, it’s vital to assess the energy usage of the machine. Some models showcase advanced technologies that reduce energy expenditure significantly. These machines often employ innovative mechanisms that optimize performance while saving electricity. However, the upfront cost may be higher.

Operating costs also play a significant role in decision-making. Regular maintenance, wear and tear, and energy use all add up. Choosing a sludge press with robust materials can minimize wear and prolong lifespan. Nonetheless, maintenance schedules can be overlooked, leading to unexpected expenses. Monitoring the operational performance can help identify areas needing improvement.

Consider the overall efficiency, including both energy consumption and maintenance needs. It’s important to balance initial investment with long-term savings. Sometimes, lower-priced models might lead to higher costs in the long run. Reflect on your specific needs and the unique operational environment. Each decision impacts the overall success of sludge management.

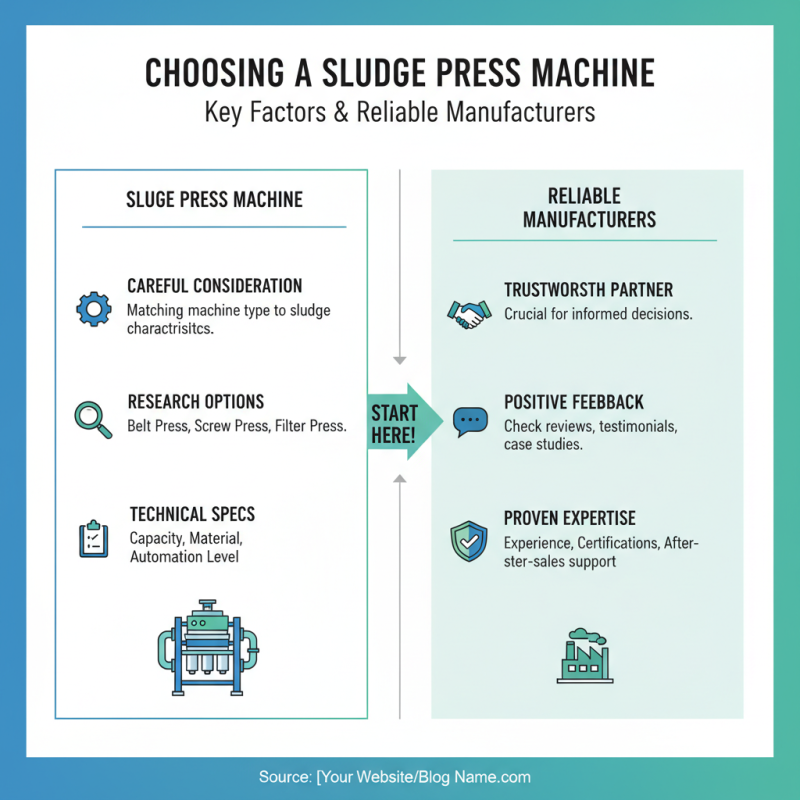

Choosing the right sludge press machine requires careful consideration. Reliable manufacturers play a key role in making an informed decision. Researching various options can be overwhelming. Start by looking for companies with positive customer feedback. This often indicates a trustworthy manufacturer.

Customer support is crucial as well. A responsive team can make a difference when you face issues. You may encounter challenges with installation or maintenance. Identify manufacturers that offer comprehensive guidance. Effective communication is essential for smooth operations. Additionally, check their warranty policies. A solid warranty can reflect the manufacturer's confidence in their product.

Reflect on your specific needs when selecting a machine. Consider the type of sludge and your processing goals. Not all suppliers provide the same level of service. Engaging with customer reviews can provide insights into their support quality. This information helps in narrowing down your choices. Finding the right manufacturer can enhance your operational efficiency.