+86 13600513715

+86 13600513715

Choosing the right Rotary Drum Filter can be challenging. With numerous options available, understanding your specific requirements is crucial. John Smith, a renowned expert in water treatment, once said, "Selecting the perfect filter is about understanding your unique needs."

A Rotary Drum Filter is essential for effective filtration in various industries. It provides superior performance and efficiency. However, not all filters suit every situation. You must consider factors like the intended application and flow rate. Everyone's needs differ.

It's easy to rush this decision. Many users overlook vital aspects. Take time to assess what you require from a Rotary Drum Filter. Is it durability or maintenance frequency? Each choice impacts your operations. Reflecting on these questions can lead to a better selection.

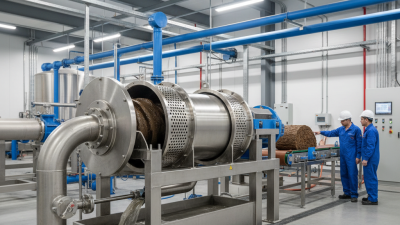

Rotary drum filters are vital for many industrial processes. They help separate solids from liquids in various applications. Understanding their functionality is essential for users. This type of filter consists of a rotating drum covered with a porous material. As the drum rotates, a vacuum draws the liquid through the filter media, leaving solids behind. This process is continuous, making it efficient for large-scale operations.

Designing a setup requires attention to several factors. One must consider the size of the drum and the type of filtration material. It’s critical to match these elements with the specific process needs. What if the wrong size is chosen? The filter may not perform adequately, leading to decreased efficiency. Additionally, the maintenance schedule plays a significant role. Regular cleaning and service are needed to ensure optimal performance.

It's important to recognize the limitations of rotary drum filters. For example, they may not handle highly viscous fluids effectively. Users should also think about space constraints in their facility. Not every setup can accommodate large drum filters. A thorough evaluation of operational requirements is crucial before making a decision. Choosing the right filter is not just about specifications. It requires a deep understanding of the entire process.

This bar chart compares the performance metrics of three different rotary drum filters. Metrics include flow rate, filtration area, power consumption, and maintenance frequency, which are crucial for selecting the best filter for specific needs.

Choosing the right rotary drum filter involves understanding your specific filtration requirements. Filtration needs can vary significantly across industries. For instance, wastewater treatment facilities may require filters that can handle high flow rates and dense solids. According to a recent industry report, 67% of operators prioritize efficiency over capacity. This insight suggests that operators should assess not only the volume of material but also the quality of filtration required.

Different applications demand different filtration mesh sizes. For example, food processing plants often need filters with finer mesh to ensure product safety. In contrast, mining operations might require coarser filters to handle larger particulates. A study highlighted that 75% of industries face issues due to inadequate filtration choices. This statistic emphasizes the importance of evaluating your unique operational challenges.

Dust and fine particles can be overlooked in preliminary assessments. Filtration systems should balance particle retention and flow rate. Evaluating the impact of lost materials can lead to costly mistakes. Regularly reviewing the effectiveness of your filtration system is crucial. The right choice can enhance productivity and reduce downtime, but considerations often shift over time. Filtration needs may evolve, so staying informed and responsive is key.

When evaluating different types of rotary drum filters, it’s essential to consider their specific applications. Some filters excel in wastewater treatment, capturing solids more efficiently. Others may perform better in industrial processes, offering varying filtration levels. Understanding the environment you’re working in can guide your choice.

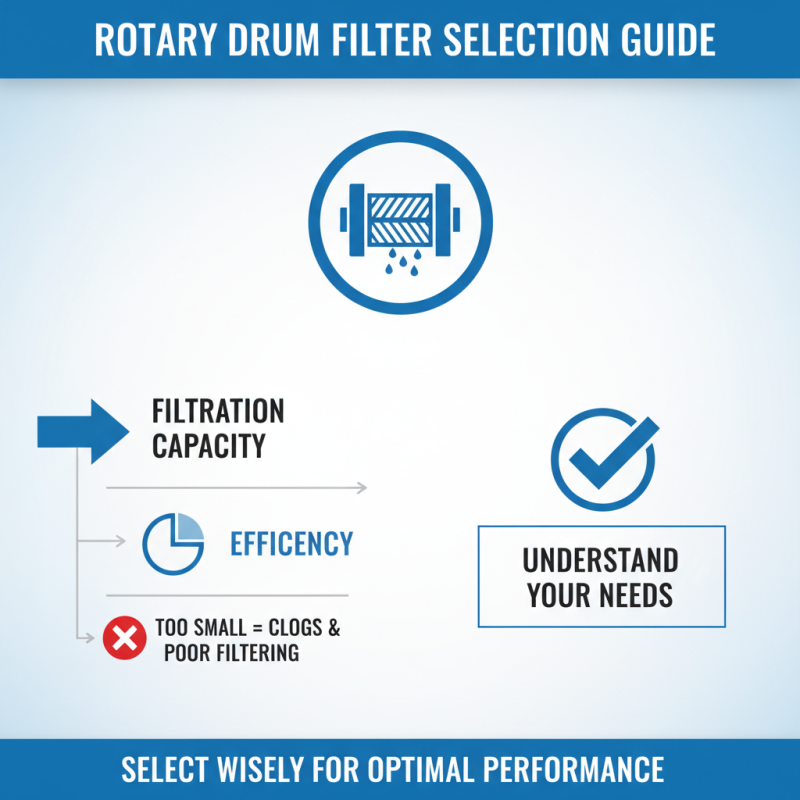

Consider the filtration rate and the size of solids the filter can handle. Options vary widely. A poorly selected filter can lead to clogs or insufficient filtration. It’s crucial to balance efficiency with maintenance needs. Too much maintenance can waste resources and time.

Additionally, materials used in filter construction matter. Some are designed for high durability, while others might not hold up well against corrosive substances. Reflect on the long-term costs of each option. Choosing a filter is not just about initial price; it’s about longevity and performance. Look for user feedback and experiences to guide your decision. This helps illuminate potential shortcomings and benefits.

When selecting a rotary drum filter, consider the filtration capacity. Capacity directly affects efficiency. A filter that is too small will struggle with high volumes. As a result, this can lead to frequent clogs and inadequate filtering. Understand your needs before making a choice.

Next, think about the material quality. Durable materials can reduce maintenance costs. Stainless steel is common, but options vary. Some may not withstand harsh conditions. Research helps in understanding which materials suit your environment best. Also, consider the ease of cleaning. A filter that traps debris easily can save you labor time.

Lastly, evaluate automation features. Some filters offer monitoring systems. These can alert you to blockages or performance issues. However, this technology can be more costly. Balance your budget against potential long-term savings. Reflecting on these features can enhance your decision-making process.

When selecting a rotary drum filter, costs and maintenance are critical factors. The initial purchase price can vary widely. Smaller models may be more affordable, but might not handle larger volumes effectively. Larger filters often provide better efficiency but come with a higher price tag. It's essential to consider your budget and operational needs before making a decision.

Maintenance is another aspect to weigh. Some filters require frequent cleaning, while others have self-cleaning features. Self-cleaning filters reduce labor costs but may have higher upfront costs. Regular maintenance is necessary for all models. Lack of proper care can lead to failure or decreased performance. Think about the time and resources you can dedicate to upkeep. It's vital to find a balance between costs and the level of maintenance you or your team can manage effectively.