+86 13600513715

+86 13600513715

Choosing the right Moving Bed Bioreactor (MBBR) can be a crucial step in optimizing your wastewater treatment processes or enhancing your biological treatment systems. With various options available in the market, selecting the most suitable model can be overwhelming. This ultimate checklist aims to simplify your decision-making by providing detailed technical specifications and practical insights on how to assess and select the best MBBR for your specific needs.

Whether you are considering factors like aeration efficiency, surface area for biofilm growth, or ease of maintenance, understanding the core aspects of MBBRs will empower you to make an informed choice that aligns with your operational goals. Let’s dive in and explore the essential criteria to keep in mind as you embark on your journey to finding the ideal Moving Bed Bioreactor.

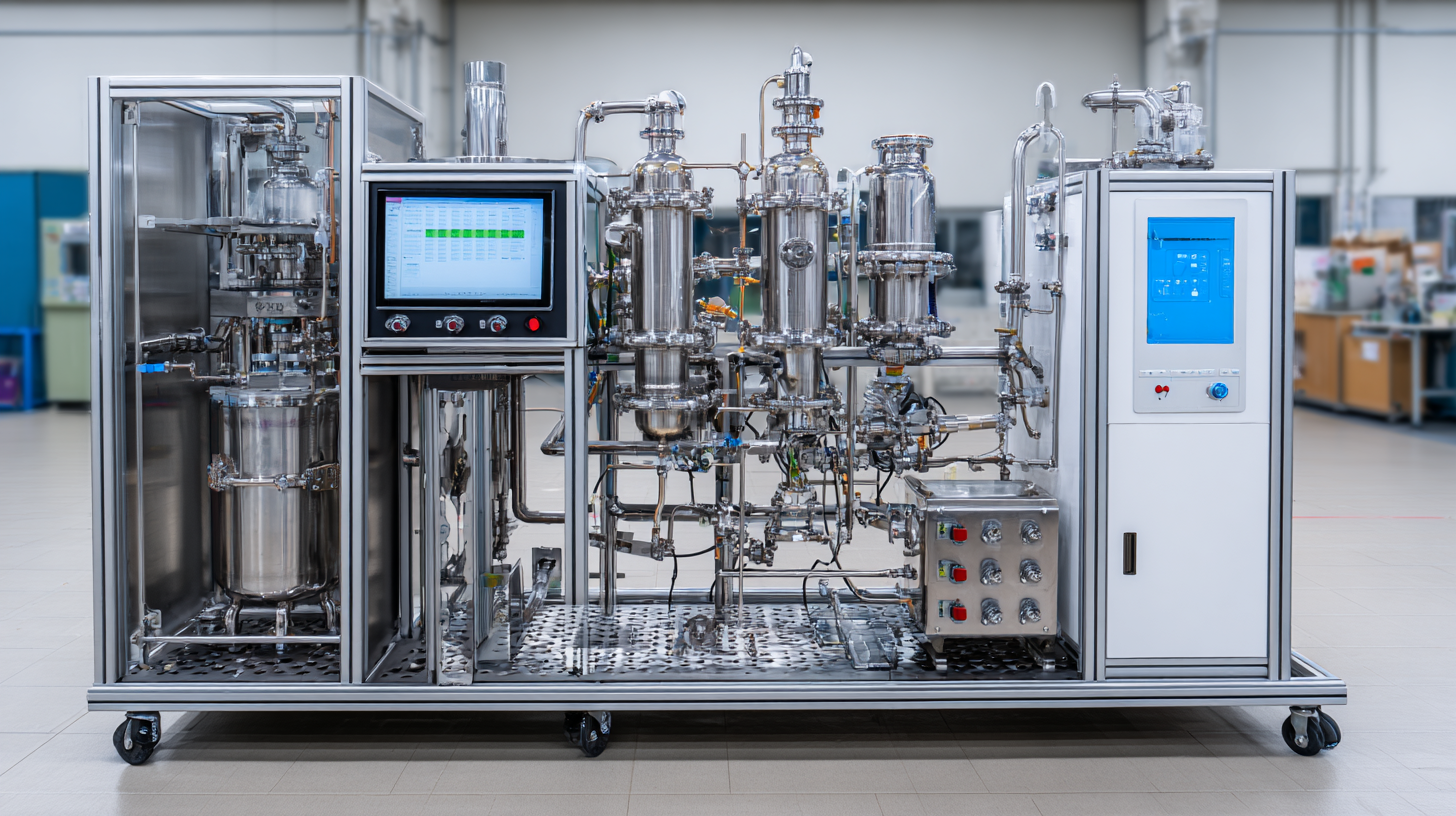

When selecting a moving bed bioreactor (MBBR) that best suits your needs, several key features should be taken into account. First and foremost, the reactor's design and materials are crucial. Look for reactors made from high-quality, durable materials that can withstand varying temperature and chemical conditions. The surface area of the media, as well as its shape and size, also play a significant role in the effectiveness of the bioreactor. A larger surface area allows for greater biofilm development, enhancing the overall efficiency of the treatment process.

Another important consideration is the hydraulic retention time (HRT) and the loading rates of the reactor. It’s essential to choose a system that offers adaptability in these parameters to accommodate varying waste loads and treatment goals. Additionally, the ease of maintenance and operation cannot be overlooked. A user-friendly design that allows for straightforward cleaning and media replacement can save time and costs in the long run. Keep these features in mind to ensure that your moving bed bioreactor operates efficiently and effectively for your specific applications.

| Feature | Importance | Considerations | Recommended Specifications |

|---|---|---|---|

| Material of Construction | High | Corrosion resistance, compatibility with media | Stainless Steel, PVC, or HDPE |

| Reactor Volume | Medium | Scalability and application requirements | 50L to 5000L |

| Bed Media Type | High | Influences biofilm growth and reaction kinetics | Plastic media, ceramics, or stainless steel |

| Hydraulic Retention Time | Medium | Impact on treatment efficiency | 1 to 24 hours, depending on application |

| Pressure Drop | High | Affects energy use and operational costs | Low pressure drop is preferred. |

| Aeration Method | Medium | Impacts oxygen transfer efficiency | Fine bubble, coarse bubble, or membrane aeration |

| Control Systems | High | Automation enhances operational efficiency | SCADA or PLC systems |

When selecting the best moving bed bioreactor (MBBR) for your needs, evaluating manufacturers’ reputation and industry experience is crucial. A well-established manufacturer typically indicates a reliable product, as longevity in the market often reflects consistent quality and robust engineering practices. Start by researching potential manufacturers’ track records: look for customer reviews, case studies, and any awards or certifications they may have received. This information can provide insight into their reliability and the performance of their products in real-world applications.

Industry experience can also significantly influence the functionality of the MBBR systems they design. Companies that have been in the industry for a considerable length of time are likely to understand the evolving technologies, regulatory changes, and the specific needs of different markets. Look into how their products have adapted over the years and whether they are at the forefront of innovation within the field. Engage with their technical support teams to gauge their expertise and responsiveness, as knowledgeable and experienced staff are essential for addressing any concerns you may encounter during installation and operation.

This bar chart illustrates the evaluation criteria and their importance when selecting a moving bed bioreactor. The key dimensions considered are 'Manufacturer Reputation', 'Industry Experience', 'Technical Support', 'Maintenance Services', and 'Cost Efficiency'.

When selecting a moving bed bioreactor, customization and flexibility play crucial roles in ensuring optimal performance and meeting specific operational needs. Each wastewater treatment process is unique, influenced by factors such as influent characteristics, treatment goals, and regulatory requirements. Therefore, a one-size-fits-all approach can limit efficiency and effectiveness. Customizing the bioreactor – from the design of the media to the dimensions and layout of the system – allows operators to tailor solutions that align perfectly with their specific conditions.

Moreover, flexibility in the bioreactor’s design allows facilities to adapt to changing requirements over time. For instance, seasonal variations in wastewater flow or shifts in treatment standards necessitate adjustments in system operations. A moving bed bioreactor that offers modular designs or scalable components can be easily modified without extensive downtime or costly upgrades. Such adaptability not only enhances operational resilience but also supports long-term sustainability by minimizing resource use and optimizing treatment efficiency.

Emphasizing customization and flexibility in bioreactor selection ensures that facilities can respond dynamically to the challenges faced in wastewater management.

When considering a moving bed bioreactor (MBBR), it is crucial to assess the cost versus benefits effectively. According to a recent study from Environmental Science & Technology, the implementation of MBBR systems can lead to operational savings of 20-30% compared to conventional methods. These savings stem from reduced energy consumption and lower chemical needs, making the initial investment a worthwhile consideration. However, potential buyers should weigh these operational efficiencies against the upfront costs, which can vary significantly, ranging from $100,000 to over $1 million, depending on system capacity and technology.

Tip: When evaluating bioreactors, consider the total cost of ownership (TCO), which includes installation, maintenance, and operational costs over the system's lifespan. This holistic view allows for a more informed decision.

Investing in a bioreactor will also depend on the specific application and desired output. Reports suggest that for wastewater treatment applications, MBBRs can enhance removal rates by 30-50%, leading to improved environmental compliance and potential regulatory savings. Understanding the specific requirements of your operation will help in aligning costs with expected benefits.

Tip: Engage with multiple vendors to compare performance metrics and long-term operational data, ensuring alignment with your facility's environmental goals and financial constraints.

When selecting the best moving bed bioreactor (MBBR) for specific applications, one pivotal factor to consider is the level of technical support and maintenance offered by suppliers. A recent industry analysis reveals that continuous support can significantly influence the operational efficiency and longevity of bioreactor systems. Suppliers that provide comprehensive maintenance packages—including routine inspections, troubleshooting services, and prompt access to replacement parts—can help minimize downtime and maintain optimal performance.

Moreover, data suggests that the overall market for MBBRs is thriving, driven by the growing demand for wastewater treatment solutions. In fact, the global market is expected to reach a valuation of over $5 billion by 2025, underlining the importance of choosing a supplier that not only meets the technical specifications of your project but also offers robust support systems. With innovations in MBBR technology continually evolving, having a supplier that can provide ongoing training and technical assistance becomes essential for operators looking to stay ahead in this competitive space.